Photosensitive compositions, hardened film, color filter, interlayer insulation film, and coating type polarizer

A technology of photosensitive composition and hardened film, which is applied in the direction of optical filters, photosensitive materials used in optical mechanical equipment, optics, etc., can solve problems such as cracks, high exposure, and transparency without consideration, and achieve bending resistance The effect of excellent performance and excellent resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

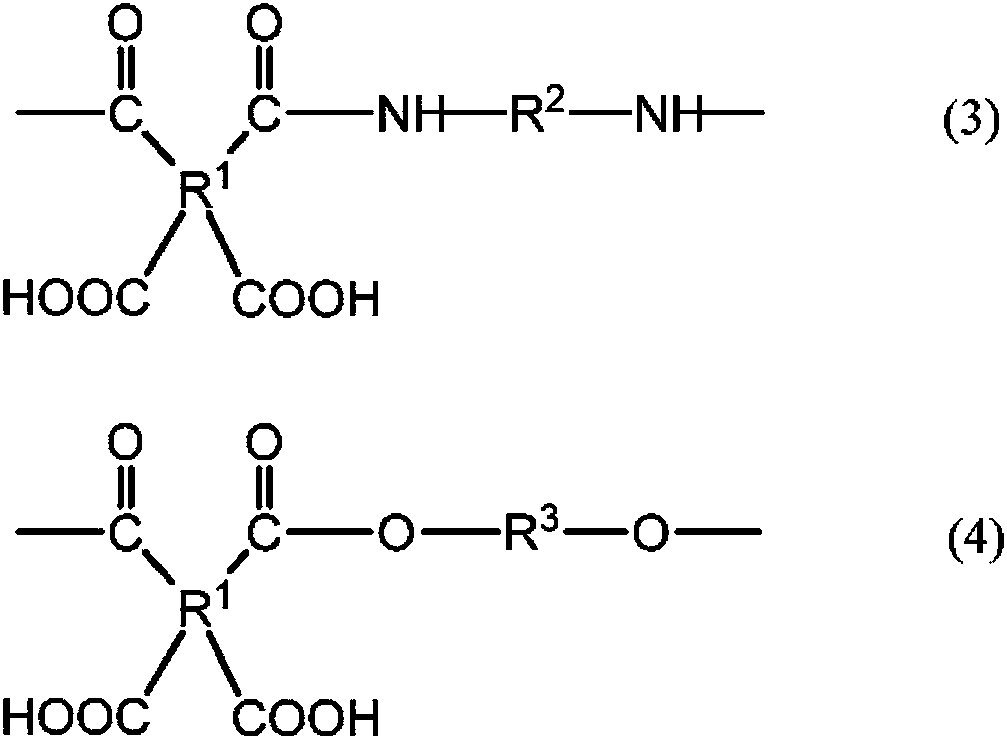

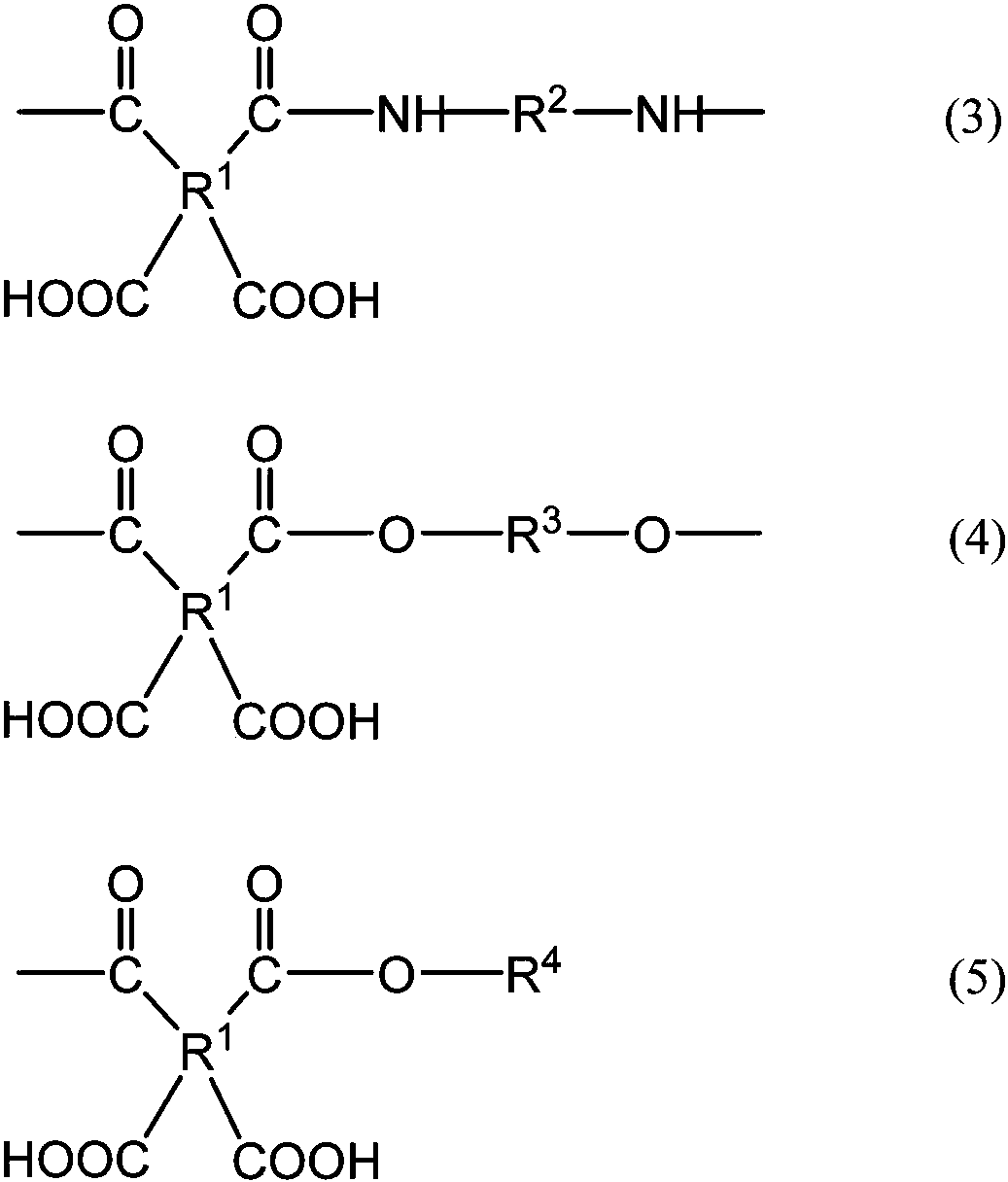

[0201] Next, the present invention will be specifically described by way of synthesis examples, examples, and comparative examples, but the present invention is not limited by these examples. First, the polyester amic-acid solution (synthesis example 1 - synthesis example 7) containing reaction products, such as a tetracarboxylic dianhydride, diamine, a monohydroxy compound, and a polyhydric hydroxy compound, was synthesize|combined as follows.

Synthetic example 1

[0202] [Synthesis Example 1] Synthesis of Polyester Amic Acid (A1) Solution

[0203] In a four-necked flask with a stirrer, dehydrated and purified methyl 3-methoxypropionate (methyl3-methoxypropionate, hereinafter referred to as "MMP"), 3,3', 4,4 '-diphenylether tetracarboxylic dianhydride (3,3',4,4'-diphenylethertetracarboxylicdianhydride, hereinafter referred to as "ODPA"), 1,4-butanediol, benzyl alcohol, under dry nitrogen flow, 125°C Stirring was carried out for 2 hours (first stage of synthesis).

[0204]

[0205] Thereafter, the reaction solution was cooled to 25°C, and 3,3'-diaminodiphenylsulfone (hereinafter referred to as "DDS") and MMP were added in the following weight, and stirred at 20°C to 30°C for 2 hours Thereafter, stirring was performed at 125° C. for 1 hour (the second stage of synthesis).

[0206] DDS 3.26g

[0207] MMP 21.00g

[0208] [Z / Y=3.0, (Y+Z) / X=0.8]

[0209] The solution was cooled to room temperature to obtain a 30% by weight solution of ...

Synthetic example 2

[0210] [Synthesis Example 2] Synthesis of Polyester Amic Acid (A2) Solution

[0211] In a four-necked flask with a stirrer, dehydrated and purified propylene glycol monomethyletheracetate (PGMEA), 1,2,3,4-butanetetracarboxylic dianhydride were loaded sequentially with the following weights: (1,2,3,4-butanetetracarboxylicdianhydride) (BT-100), SMA1000P (trade name; styrene-maleic anhydride copolymer, Chuanyuan Petrochemical Co., Ltd.), 1,4-butanediol, benzyl alcohol, Stirring was carried out at 125° C. for 2 hours under a stream of dry nitrogen (first stage of synthesis).

[0212]

[0213] Thereafter, the reaction solution was cooled to 25° C., DDS and PGMEA were charged in the following weights, and stirred at 20° C. to 30° C. for 2 hours, and then at 125° C. for 1 hour (synthesis second stage).

[0214] DDS 1.20g

[0215] PGMEA 16.51g

[0216] [Z / Y=2.7, (Y+Z) / X=0.9]

[0217] The solution was cooled to room temperature to obtain a 30% by weight solution of a pale yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com