Toilet paper and preparation method thereof

A technology for toilet paper modification, which is applied in the field of toilet paper preparation, and can solve problems such as unsatisfactory antibacterial and antifungal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

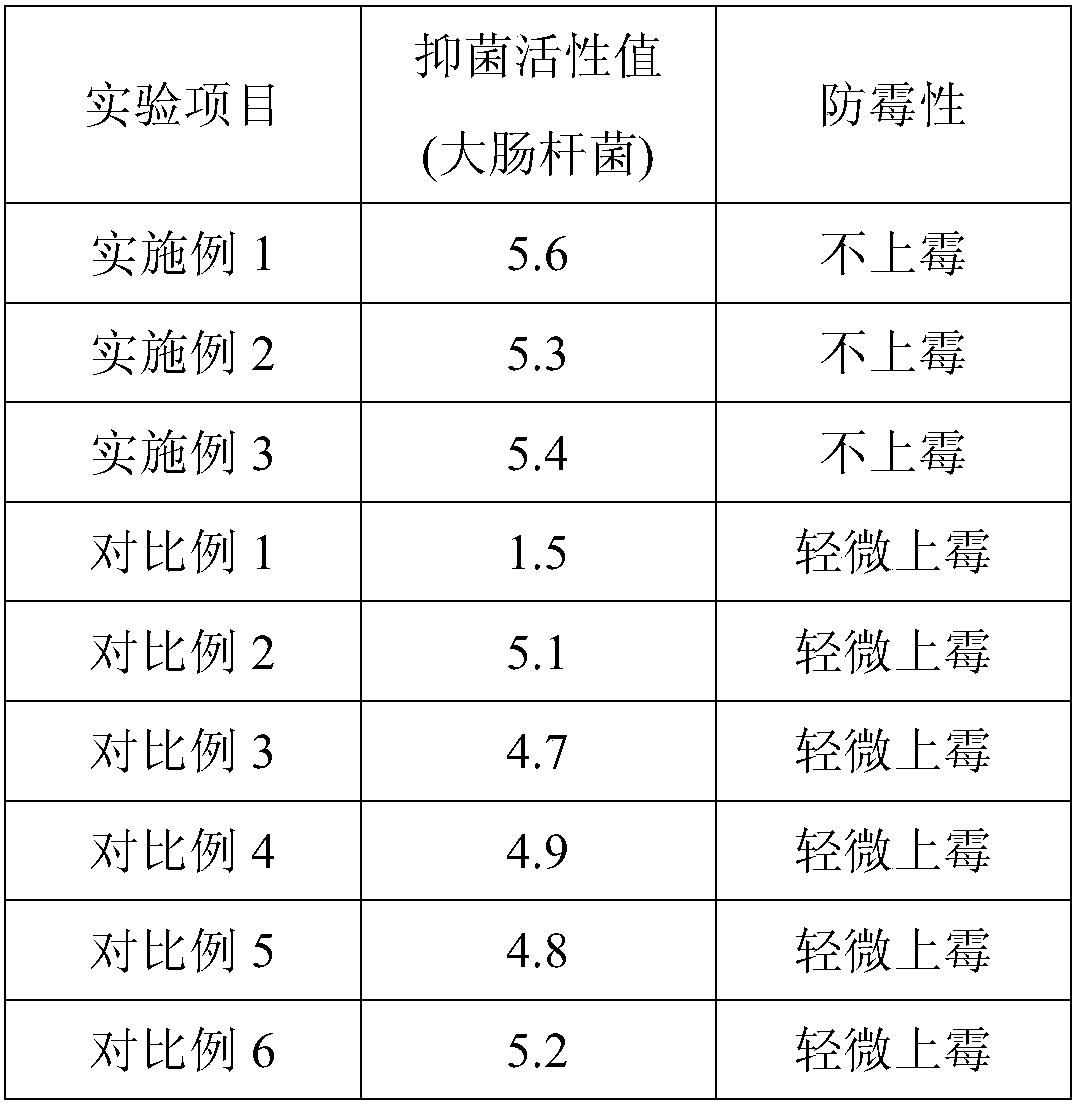

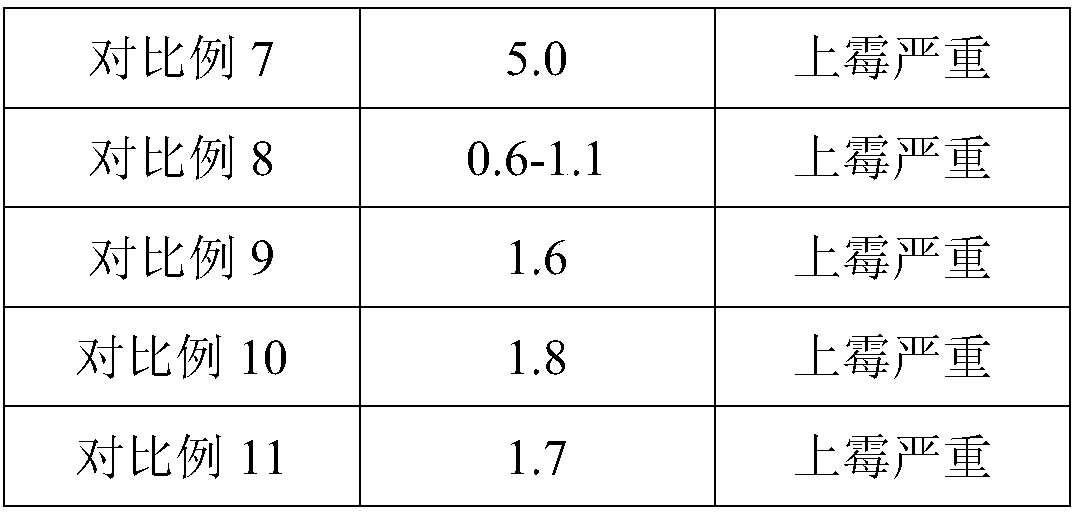

Examples

preparation example Construction

[0028] The preparation method of described toilet paper, comprises the following steps:

[0029] S1: Mix polylactic acid and melamine resin evenly, heat up to 80-90°C, keep warm for 10-20min, then add bamboo charcoal fiber, antibacterial modification additive and anti-mildew modification additive and mix evenly, at 1500-2500r / min Stir at 1600-1800r / min for 20-40min, heat up to 110-120°C, keep warm for 15-25min, then add 1,3-butanediol and mix evenly, stir at 1600-1800r / min for 20-40min, cool to room temperature to obtain the modified material;

[0030] S2: Add paeonol, potato extract, lemon extract, mugwort oil and Houttuynia cordata into grass pulp, stir at 300-600 rpm for 15-20 minutes, then add modified material, polyethyleneimine Stir with balsam pear juice evenly, then produce large rolls of toilet paper according to the conventional method, so that the moisture content of the toilet paper is above 8%, and then cut, seal and pack to obtain toilet paper.

Embodiment 1

[0032] A toilet paper, in parts by weight, comprising the following raw materials: 28.9 parts of paeonol, 14.6 parts of potato extract, 6.8 parts of lemon extract, 11.3 parts of mugwort oil, 16.9 parts of Houttuynia cordata, 2.4 parts of polyethyleneimine, balsam pear 5.2 parts of juice, 6.8 parts of polylactic acid, 5.6 parts of bamboo charcoal fiber, 19.7 parts of antibacterial modified additives, 14.5 parts of anti-mildew modified additives, 8.4 parts of melamine resin, 3.2 parts of 1,3-butanediol.

[0033] The antibacterial modified auxiliary agent is prepared according to the following process: 14 parts by weight of urea, 5.8 parts of polyvinylpyrrolidone and 26.8 parts of deionized water are mixed evenly, and then 5.7 parts of sodium chloride and 6.9 parts of emulsified silicone oil are added and stirred for 23.4min , then add 5.7 parts of zinc oxide to obtain material a; mix 7.4 parts of natural zeolite and 13.4% sodium chloride solution with a mass fraction of 13.4%, st...

Embodiment 2

[0039] A toilet paper, in parts by weight, comprising the following raw materials: 15 parts of paeonol, 15 parts of potato extract, 4 parts of lemon extract, 12 parts of mugwort oil, 15 parts of Houttuynia cordata, 3 parts of polyethyleneimine, balsam pear 4 parts of juice, 9 parts of polylactic acid, 4 parts of bamboo charcoal fiber, 25 parts of antibacterial modified auxiliary agent, 10 parts of anti-mildew modified auxiliary agent, 9 parts of melamine resin, 2 parts of 1,3-butanediol.

[0040] The antibacterial modified auxiliary agent is prepared according to the following process: mix 10 parts of urea, 8 parts of polyvinylpyrrolidone and 15 parts of deionized water in parts by weight, then add 8 parts of sodium chloride and 4 parts of emulsified silicone oil and stir for 30 minutes, Then add 3 parts of zinc oxide to obtain material a; 8 parts of natural zeolite and 5% sodium chloride solution are mixed evenly, stirred for 3 hours, filtered and dehydrated, dried, then roast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com