Preparation method for modified aniline terpolymer/water-based resin composite anti-corrosive coating

A technology of aniline terpolymer and phenylenediamine terpolymer, which is applied in the field of preparation of modified aniline terpolymer/water-based resin composite anti-corrosion coatings, can reduce rigidity and conjugation effect, improve dispersibility, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

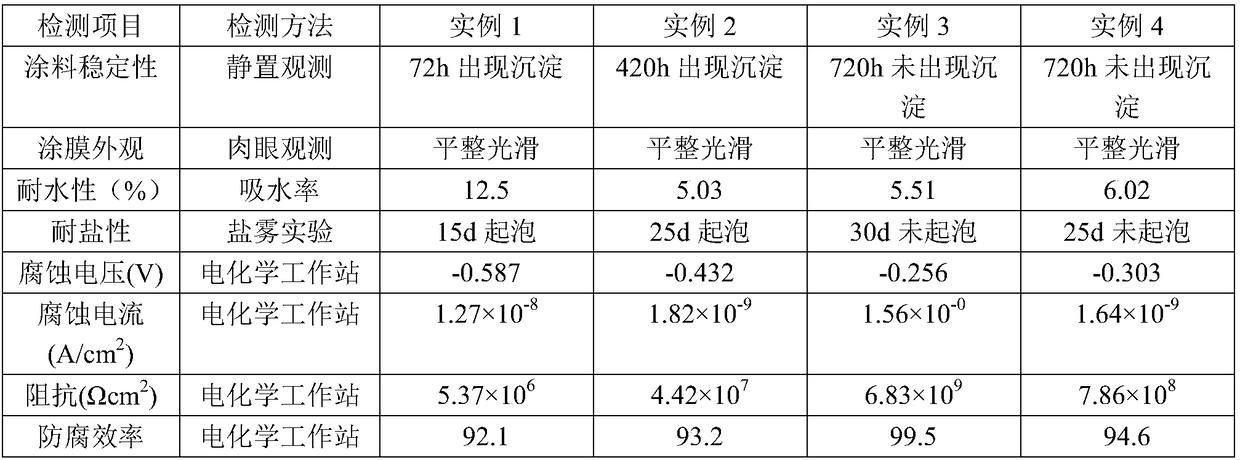

Examples

preparation example Construction

[0027] A preparation method of modified aniline terpolymer / water-based resin composite anticorrosion coating, the preparation steps are as follows:

[0028] Step 1) prepare modified aniline terpolymer

[0029] a. In parts by weight, first ultrasonically disperse 0.5 to 1.5 parts of o-hydroxyaniline and 2 to 3.8 parts of surfactants with sulfonic acid groups into 80 to 150 parts of doped acid solutions with a concentration of 1mol / L, and The dispersed aqueous solution is moved into a reactor and stirred in an ice bath for 20-40 minutes to obtain a mixed liquid A; wherein, the surfactant with a sulfonic acid group is p-toluenesulfonic acid or anthraquinone disulfonic acid. The doping acid is hydrochloric acid or citric acid. The oxidizing agent is ammonium persulfate or potassium persulfate.

[0030] b. Weigh 3 to 5 parts of aniline, and dissolve 4 to 7 parts of oxidizing agent in 80 to 150 parts of doping acid solution to prepare oxidizing agent / acid solution, then add anilin...

Embodiment 1

[0038] In parts by weight, first ultrasonically disperse 0.5 parts of o-hydroxyaniline and 2 parts of p-toluenesulfonic acid into 80 parts of hydrochloric acid solution with a concentration of 1mol / L, move the dispersed aqueous solution to the reactor and stir in an ice bath Mixed solution A was prepared in 20 minutes; 3.5 parts of aniline were weighed, and 4 parts of ammonium persulfate were dissolved in 150 parts of hydrochloric acid solution to obtain ammonium persulfate / acid solution, and then in mixed solution A, aniline and Ammonium persulfate / acid solution, the dropping time is 1 hour; subsequently, weigh 0.3 parts of p-phenylenediamine and dissolve it in 8 parts of absolute ethanol, and add the dissolved p-phenylenediamine solution dropwise to the reaction After the dropwise addition is completed, the reaction system continues to react in an ice-water bath for 3 hours to obtain an aniline-o-hydroxyaniline-p-phenylenediamine terpolymer solution; vacuum filter the terpoly...

Embodiment 2

[0042] In parts by weight, first 1.2 parts of o-hydroxyaniline and 3.8 parts of p-toluenesulfonic acid are ultrasonically dispersed into 150 parts of citric acid solution with a concentration of 1mol / L, and the dispersed aqueous solution is moved to the reactor and placed in an ice bath. Stir for 40 minutes to prepare mixed solution A; weigh 4 parts of aniline, and dissolve 5 parts of potassium persulfate in 80 parts of citric acid solution to prepare potassium persulfate / acid solution, and then add dropwise to mixed solution A Aniline and potassium persulfate / acid solution, the dropping time is 1.2 hours; subsequently, weigh 1.3 parts of p-phenylenediamine and dissolve it in 15 parts of absolute ethanol, and add the dissolved p-phenylenediamine solution dropwise into the reactor; after the dropwise addition was completed, the reaction system continued to react in an ice-water bath for 4 hours to obtain an aniline-o-hydroxyaniline-p-phenylenediamine terpolymer solution; the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com