Color-changing polyurethane acrylic dyestuff resin and preparation method

A polyurethane acrylic and dye resin technology, applied in dyeing, textile and papermaking, etc., can solve the problems of high hardness, poor solvent resistance, low tensile strength, etc., and achieve bright colors, good color fastness, non-toxic use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

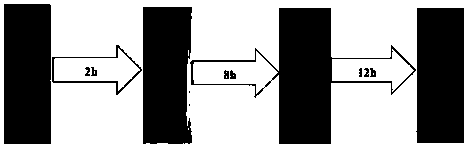

Method used

Image

Examples

Embodiment 1

[0021] Take 0.15 mol of polytetrahydrofuran glycol 800 and add it to a four-necked flask equipped with a thermometer, agitator, reflux condenser and dropping funnel. The temperature is raised to 110°C and dehydrated. After 1 hour, nitrogen is introduced to cool to 80°C, and 0.30 mol is added. Isophorone diisocyanate (IPDI) and 0.0003mol stannous octoate (T 9 ), keep for 3h, add 40ml methyl ethyl ketone to adjust the viscosity, cool to 60℃, add 0.12mol Sudan orange G, heat up 90℃, and react for about 3h. Reduce the temperature to 85°C, add 0.035mol hydroxypropyl acrylate (HPA), react for about 3h, add 40ml acetone to adjust the viscosity. Reduce the temperature to 70°C, add 0.1 mol acrylate, 0.1 mol methyl methacrylate, and azobisisobutyronitrile in batches, with an interval of 20 minutes each time, about 3 hours to complete the addition, and keep the temperature for 5 hours. The temperature is increased to 110°C, the solvent is removed in a vacuum, and it is naturally lowered t...

Embodiment 2

[0024] Take 0.15 mol of polyoxypropylene glycol and add it to a four-necked flask equipped with a thermometer, agitator, reflux condenser and dropping funnel. The temperature is raised to 110°C and dehydrated. After 1 hour, the temperature is reduced to 80°C by nitrogen gas, and 0.30 mol is added. 4,4-Diphenylmethane diisocyanate (MDI) and 0.0003mol dibutyltin dilaurate (T 12 ), heat preservation for 3h, add 40ml methyl ethyl ketone to adjust the viscosity, reduce the temperature to 60℃, add 0.12mol Sudan orange G, increase the temperature at 80℃, and react for about 3h. Add 0.035mol of hydroxypropyl acrylate (HPA), react for about 3h, and add 40ml of acetone to adjust the viscosity. Reduce the temperature to 70°C, add 0.1 mol methyl methacrylate, 0.1 mol styrene, and azobisisobutyronitrile in batches, with an interval of 20 minutes each time, about 3 hours to complete the addition, and heat preservation for 6 hours. The temperature is increased to 110°C, the solvent is removed...

Embodiment 3

[0027] Take 0.16 mol of polytetrahydrofuran glycol 1000, add it to a four-necked flask equipped with a thermometer, stirrer, reflux condenser and dropping funnel, heat it up to 110℃, dehydrate, after 1h, blow in nitrogen to cool to 90℃, add 0.30 mol Hexamethylene diisocyanate (HDI) and 0.0003mol stannous octoate (T 9 ), heat preservation for 3h, add 40ml methyl ethyl ketone to adjust the viscosity, cool to 60℃, add 0.05mol solvent orange 3 and 0.05 Sudan orange G, increase the temperature at 90℃, and react for about 3h. Add 0.045 mol of hydroxyethyl methacrylate (H E M A), react for about 3 hours, and add 40 ml of acetone to adjust the viscosity. Reduce the temperature to 70°C, add 0.1 mol acrylate, 0.1 mol methyl methacrylate, and benzoyl peroxide in batches, with an interval of 20 minutes each time, approximately 3 hours to complete the addition, and keep the temperature for 5 hours. The temperature is increased to 110°C, the solvent is removed in a vacuum, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com