Granular compound fertilizer produced by utilizing phosphoric acid residue and production method of granular compound fertilizer

A technology of phosphoric acid slag acid and compound fertilizer, which is applied in the direction of urea compound fertilizer, application, nitrogen fertilizer, etc., can solve the problems of difficult discharge of phosphogypsum, low production economic benefit, high production cost, etc., to achieve comprehensive utilization of resources and improve economic benefits of enterprises , Improve the effect of fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

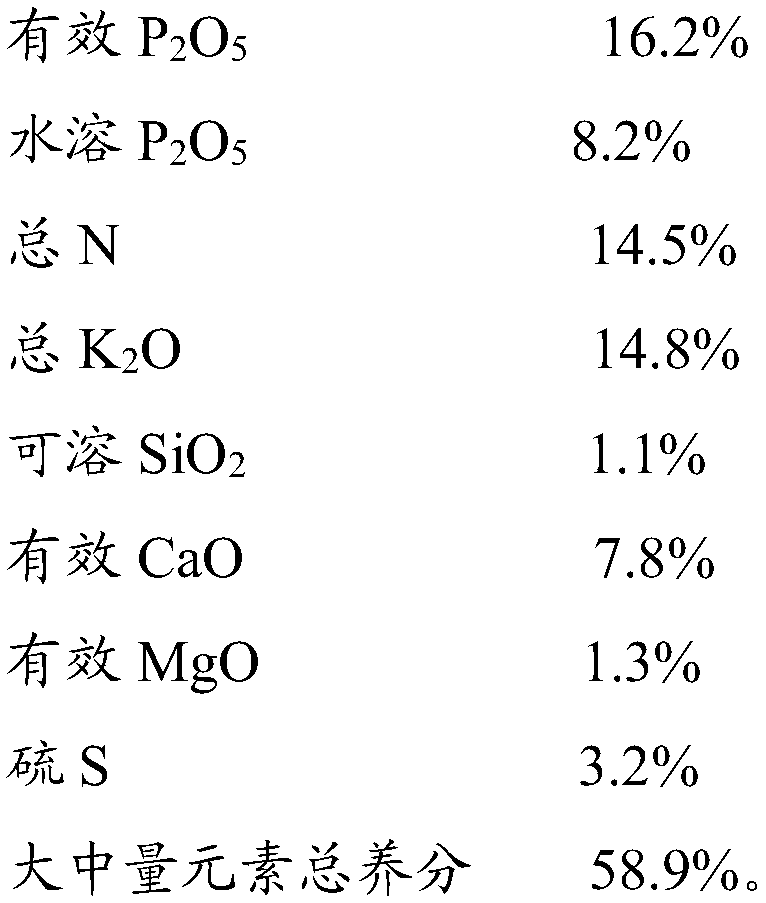

Embodiment 1

[0067] Embodiment 1: produce functional compound fertilizer with phosphoric acid slag acid

[0068] The steps of this method are as follows:

[0069] A. Preparation of urea sulfuric acid solution

[0070] Solid urea, sulfuric acid with a concentration of 98% by weight and water are mixed and dissolved according to a mass ratio of 6.6:5.8:1.0 to obtain a urea-sulfuric acid solution, and the solution is kept at a temperature of 75°C;

[0071] B. Decomposition of phosphate rock

[0072] Will P 2 o 5 The phosphate rock with a content of 6% by weight is crushed into phosphate rock powder with a particle size of 0.147 mm; and then water is used to make the phosphate rock powder with a concentration of 70% by weight of phosphate rock slurry;

[0073] According to the mass ratio of solid urea and phosphate rock slurry 1:2.0, add the phosphate rock slurry to the urea sulfuric acid solution obtained in step A, mix well, and react at a temperature of 80°C for 3.3h; then follow the so...

Embodiment 2

[0080] Embodiment 2: produce functional compound fertilizer with phosphoric acid slag acid

[0081] The steps of this method are as follows:

[0082] A. Preparation of urea sulfuric acid solution

[0083] Solid urea, sulfuric acid with a concentration of 98% by weight and water are mixed and dissolved according to the mass ratio of 6.4:5.2:1.0 to obtain a urea-sulfuric acid solution, and the solution is kept at a temperature of 80°C;

[0084] B. Decomposition of phosphate rock

[0085] Will P 2 o 5 The phosphate rock with a content of 22% by mass is crushed into phosphate rock powder with a particle size of 0.175 mm; and then water is used to make the phosphate rock powder with a concentration of 60% by weight of phosphate rock slurry;

[0086] According to the mass ratio of solid urea and phosphate rock slurry 1:1.8, add the phosphate rock slurry to the urea sulfuric acid solution obtained in step A, mix well, and react at a temperature of 75°C for 3.0h; then follow the s...

Embodiment 3

[0093] Embodiment 3: produce functional compound fertilizer with phosphoric acid slag acid

[0094] The steps of this method are as follows:

[0095] A. Preparation of urea-sulfuric acid solution

[0096] Solid urea, sulfuric acid with a concentration of 98% by weight and water are mixed and dissolved according to a mass ratio of 6.8:5.6:1.0 to obtain a urea-sulfuric acid solution, and the solution is kept at a temperature of 85°C;

[0097] B. Decomposition of phosphate rock

[0098] Will P 2 o 5 The phosphate rock with a content of 10% by mass is crushed into phosphate rock powder with a particle size of 0.125mm; and then water is used to make the phosphate rock powder with a concentration of 65% by mass into a phosphate rock slurry;

[0099] According to the mass ratio of solid urea and phosphate rock slurry 1:2.2, add the phosphate rock slurry to the urea sulfuric acid solution obtained in step A, mix well, and react at a temperature of 85°C for 4.0h; then follow the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com