B,N-codoped porous carbon nanosheet and preparation method and usage thereof

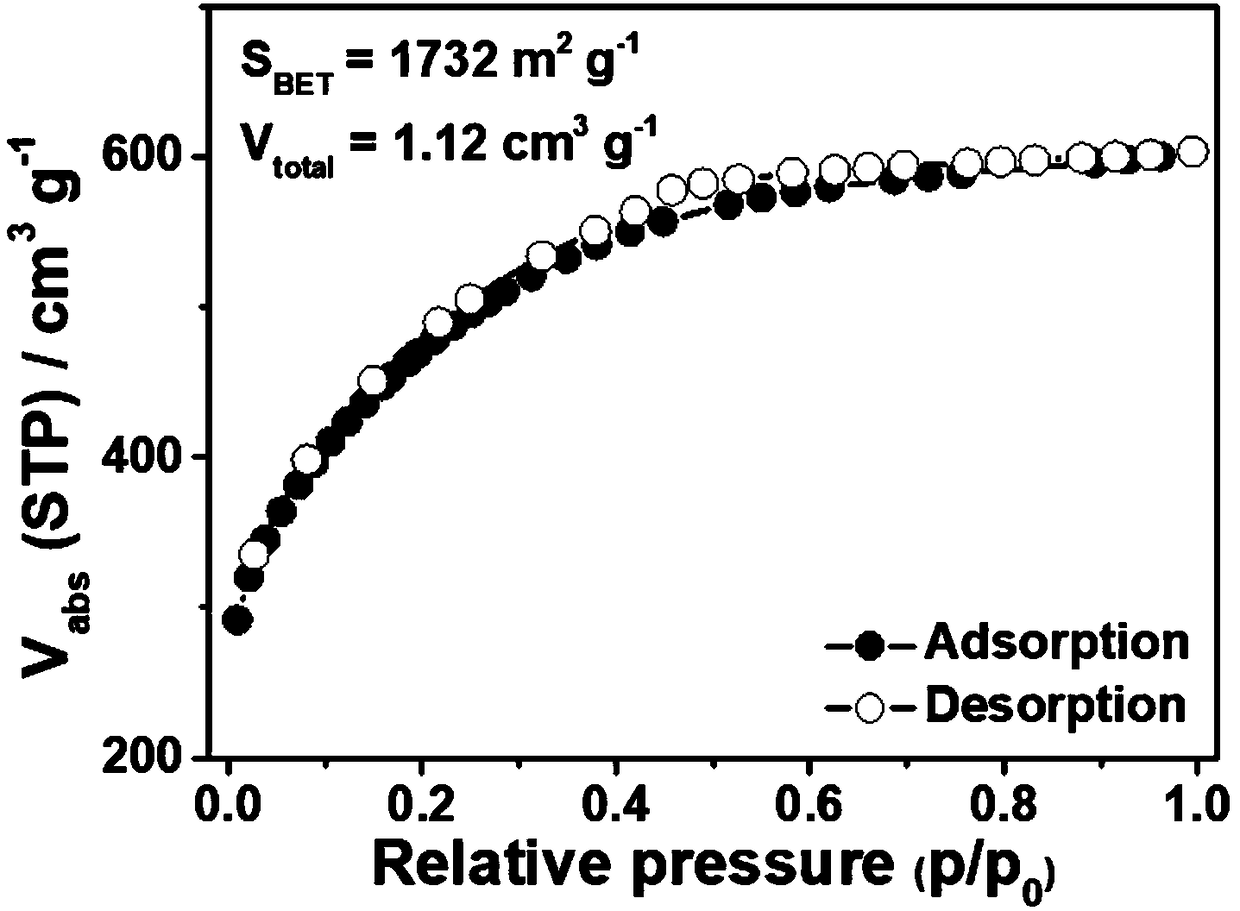

A technology of porous carbon and nanosheets, which is applied in the fields of nanocarbon, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of complicated preparation process, disadvantageous low-cost production of carbon nanosheets, etc. Electrochemical performance, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0070] Mix and dissolve 5g of bis(2-chloroethyl)amine hydrochloride and 15g of NaOH in 100mL of water, stir at room temperature for 2.5 hours, let stand for 1 hour and separate the layers, separate the light yellow viscous liquid in the lower layer and wash with distilled water Wash until neutral, and dry in vacuum to obtain di(2-chloroethyl)amine.

[0071] Then, mix and dissolve 2g of bis(2-chloroethyl)amine and 8g of boric acid in 50mL of DMF, and put it in an oil bath at 70°C for 2.5h. After the reaction is completed, add 95% ethanol, pour it out while it is hot, cool naturally, and precipitate Crystallization gives two (2-chloroethyl) aminoboronic acid.

[0072] Next, 1 g of bis(2-chloroethyl)aminoboronic acid was placed in a high-temperature tube furnace under N 2 The temperature was raised to 800°C at a rate of 4°C / min under the protection of , and carbonized for 2 hours. The carbonized material was washed with distilled water until neutral, and finally the product was...

example 2

[0075] Mix and dissolve 5g of bis(2-chloroethyl)amine hydrochloride and 20g of KOH in 100mL of water, stir at room temperature for 4h, let stand for 2h and then separate layers, separate the lower layer of light yellow viscous liquid and wash with distilled water To neutrality, vacuum drying to obtain two (2-chloroethyl) amine.

[0076] Then, mix and dissolve 2g of bis(2-chloroethyl)amine and 6g of boric acid in 50mL of DMF, and put it in an oil bath at 80°C for 3h. After the reaction is completed, add 90% ethanol, pour it out while it is hot, and let it cool naturally to precipitate crystals. , to obtain bis(2-chloroethyl)aminoboronic acid, which was obtained by extraction and rotary evaporation to obtain bis(2-chloroethyl)aminoboronic acid.

[0077] Next, 1 g of bis(2-chloroethyl)aminoboronic acid was placed in a high-temperature tube furnace under N 2 Under the protection of , the temperature was raised to 700°C at a rate of 3°C / min, and carbonized for 3h. The carbonized ...

example 3

[0080] Mix and dissolve 5g of bis(2-chloroethyl)amine hydrochloride and 10g of NaOH in 100mL of water, stir at room temperature for 2h, let it stand for 0.8h and then separate the layers, separate the lower layer of light yellow viscous liquid and wash with distilled water Wash until neutral, and dry in vacuum to obtain two (2-chloroethyl) amine.

[0081] Then, mix and dissolve 2g of bis(2-chloroethyl)amine and 10g of boric acid in 50mL of DMF, and place it in an oil bath at 60°C for 2.5h. After the reaction is completed, add 90% ethanol, pour it out while it is hot, cool naturally, and precipitate Crystallization gives bis(2-chloroethyl)aminoboronic acid.

[0082] Next, 1 g of bis(2-chloroethyl)aminoboronic acid was placed in a high-temperature tube furnace under N 2 The temperature was raised to 900°C at a rate of 6°C / min under the protection of , and carbonized for 2 hours. The carbonized material was washed with distilled water to neutrality, and finally the product was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com