Preparation method of copper/alumina in-situ composite honeycomb material

An in-situ composite, honeycomb material technology, applied in the field of porous composite materials, can solve the problems of high cost of main raw materials, high production cost, low interface bonding strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

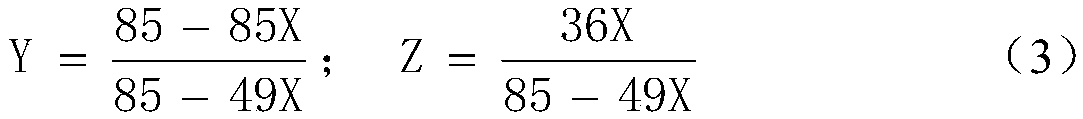

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of a kind of copper / alumina in-situ composite honeycomb material of this embodiment, such as figure 1 As shown, the specific steps are as follows:

[0041] (1) Homogenous mixing and refining: firstly mix 200 purpose commercially available industrial pure aluminum powder and 400 purpose commercially available industrial copper oxide powder according to the proportion that aluminum powder accounts for 1.3% of the total mass of aluminum powder and copper oxide powder to obtain mixed powder , then the plasticizer and water are uniformly mixed according to the ratio of the plasticizer to 25% of the total mass of the plasticizer and water to obtain a mixture, and finally the mixed powder of aluminum powder, copper oxide powder, plasticizer and water are mixed according to The mixed powder accounts for 80% of the total mass of the mixed powder and the mixed mixture, and the plasticizer is polyvinyl alcohol;

[0042] (2) Extrusion of honeycomb structure:...

Embodiment 2

[0047] In this embodiment, a method for preparing a copper / alumina in-situ composite honeycomb material, the specific steps are as follows:

[0048] (1) Homogenous mixing and refining: firstly mix 300 purpose commercially available industrial pure aluminum powder and 500 purpose commercially available industrial copper oxide powder according to the proportion that aluminum powder accounts for 2.3% of the total mass of aluminum powder and copper oxide powder to obtain mixed powder , then the plasticizer and water are uniformly mixed according to the ratio of the plasticizer to 30% of the total mass of the plasticizer and water to obtain a mixture, and finally the mixed powder of aluminum powder, copper oxide powder, plasticizer and water are mixed according to The mixed powder accounts for 82% of the total mass of the mixed powder and the mixed mixture, and the plasticizer is polyvinyl alcohol;

[0049](2) Extrusion of honeycomb structure: put the mixed material prepared in ste...

Embodiment 3

[0054] In this embodiment, a method for preparing a copper / alumina in-situ composite honeycomb material, the specific steps are as follows:

[0055] (1) Homogenous mixing and refining: firstly mix 300 purpose commercially available industrial pure aluminum powder and 500 purpose commercially available industrial copper oxide powder according to the proportion that aluminum powder accounts for 3.1% of the total mass of aluminum powder and copper oxide powder to obtain mixed powder , then the plasticizer and water are uniformly mixed according to the ratio of the plasticizer to 35% of the total mass of the plasticizer and water to obtain a mixture, and finally the mixed powder of aluminum powder, copper oxide powder, plasticizer and water are mixed according to Mixed powder accounts for 84% of the total mass of mixed powder and mixture mixed kneading material, plasticizer is methyl cellulose;

[0056] (2) Extrusion of honeycomb structure: put the mixed material prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com