Laminated member with hard coating and preparation method of laminated member

A hard coating and coating technology, which is applied in the direction of coating, metal material coating process, sputtering plating, etc., can solve the problems that cannot meet the high-speed cutting of stainless steel well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The above-mentioned preparation method of the covered part 10 with a hard coating mainly includes the following steps:

[0033] A hard substrate 20 is provided, and the hard substrate 20 is decontaminated and cleaned. In this cleaning step, the hard substrate 20 can be placed in an ultrasonic cleaner filled with ethanol and / or acetone solution for vibration cleaning, so as to remove impurities and oil stains on the surface of the hard substrate 20, and then dried for later use.

[0034] Take the composition as Ti X Al Y m Z The composite target is the target material, and the hard substrate 20 is subjected to vacuum coating treatment, so as to coat the bonding layer 30 and the hard coating layer 40 on the hard substrate 20 . The bonding layer 30 is located between the hard substrate 20 and the hard coating 40 .

[0035] The vacuum coating process steps are as follows:

[0036] see figure 2 , a magnetron sputtering device 1 is provided, and the magnetron sputterin...

Embodiment 1-3

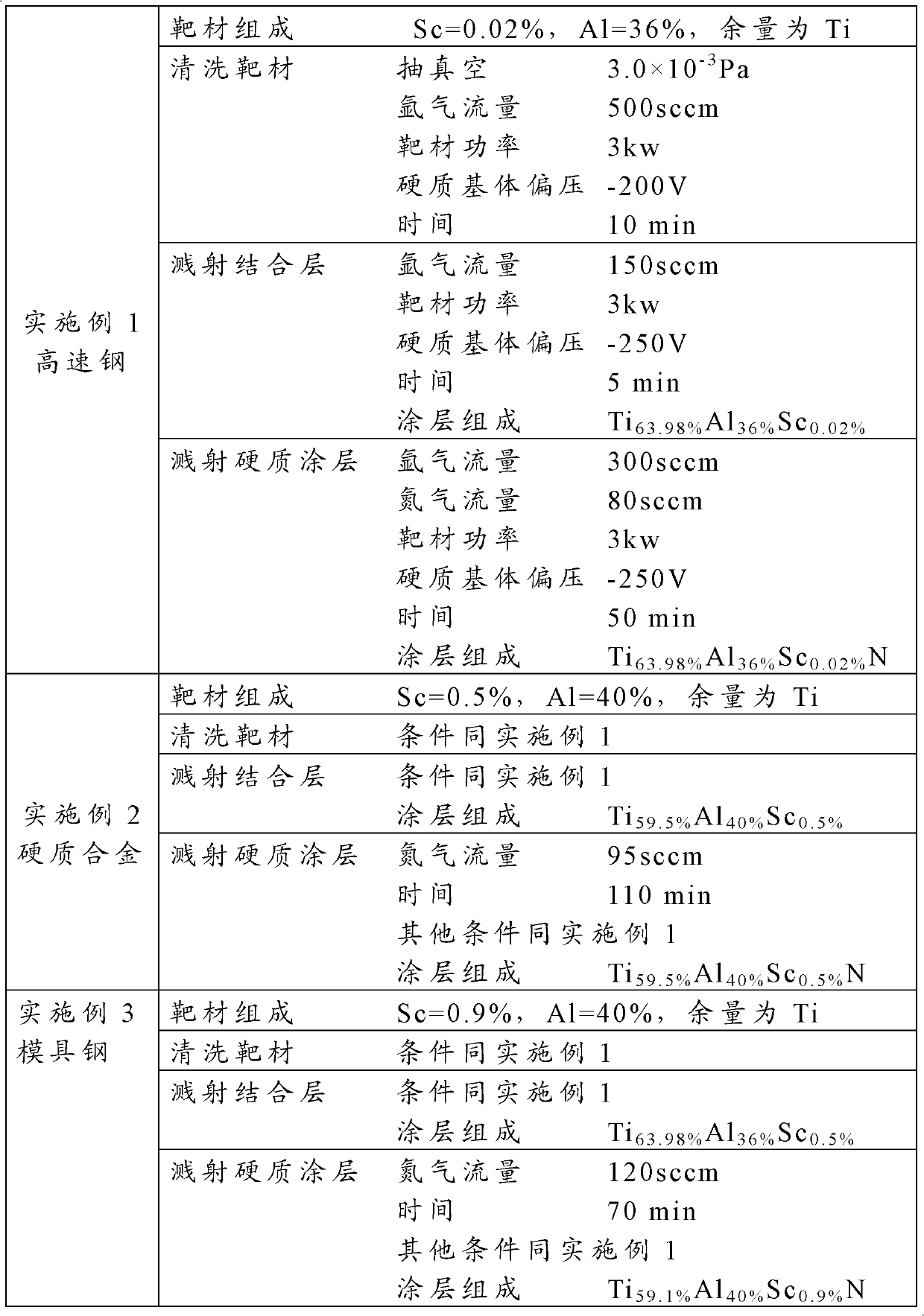

[0043]The materials for the hard substrates in Examples 1-3 are high-speed steel, cemented carbide, and die steel, and the samples of the hard substrates are placed in an ultrasonic cleaner filled with ethanol solution for vibration cleaning and then dried.

[0044] to Ti X al Y sc Z is the target material, and the specific composition of the target material is shown in Table 1. Vacuum coating treatment is performed on the hard substrate sample. The vacuum coating process includes sputtering to clean the target material, sputtering the bonding layer on the hard substrate sample and sputtering the hard coating on the bonding layer. The operation of the vacuum coating process is as described above, and the process conditions of each step of vacuum coating are shown in Table 1.

Embodiment 4-6

[0046] Examples 4-6 The materials selected for the hard substrates are high-speed steel, hard alloy and die steel respectively. Different from Example 1-3, the target material of Example 4-6 is Ti X al Y Dy Z , and the values of X, Y and Z in the targets of Examples 4-6 are the same as those of Examples 1-3. In addition, the process conditions of each step of Examples 4-6 are respectively the same as those of Examples 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com