Petroleum barrel cleaning equipment for petroleum refining

A technology for cleaning equipment and oil drums, which is applied to the field of oil drum cleaning equipment for petroleum refining, can solve the problems of reduced impact force of water flow, easy to wear rods, waste of water resources, and work efficiency, so as to improve the driving force, improve work efficiency, Optimizing the effect of the internal pressurization structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

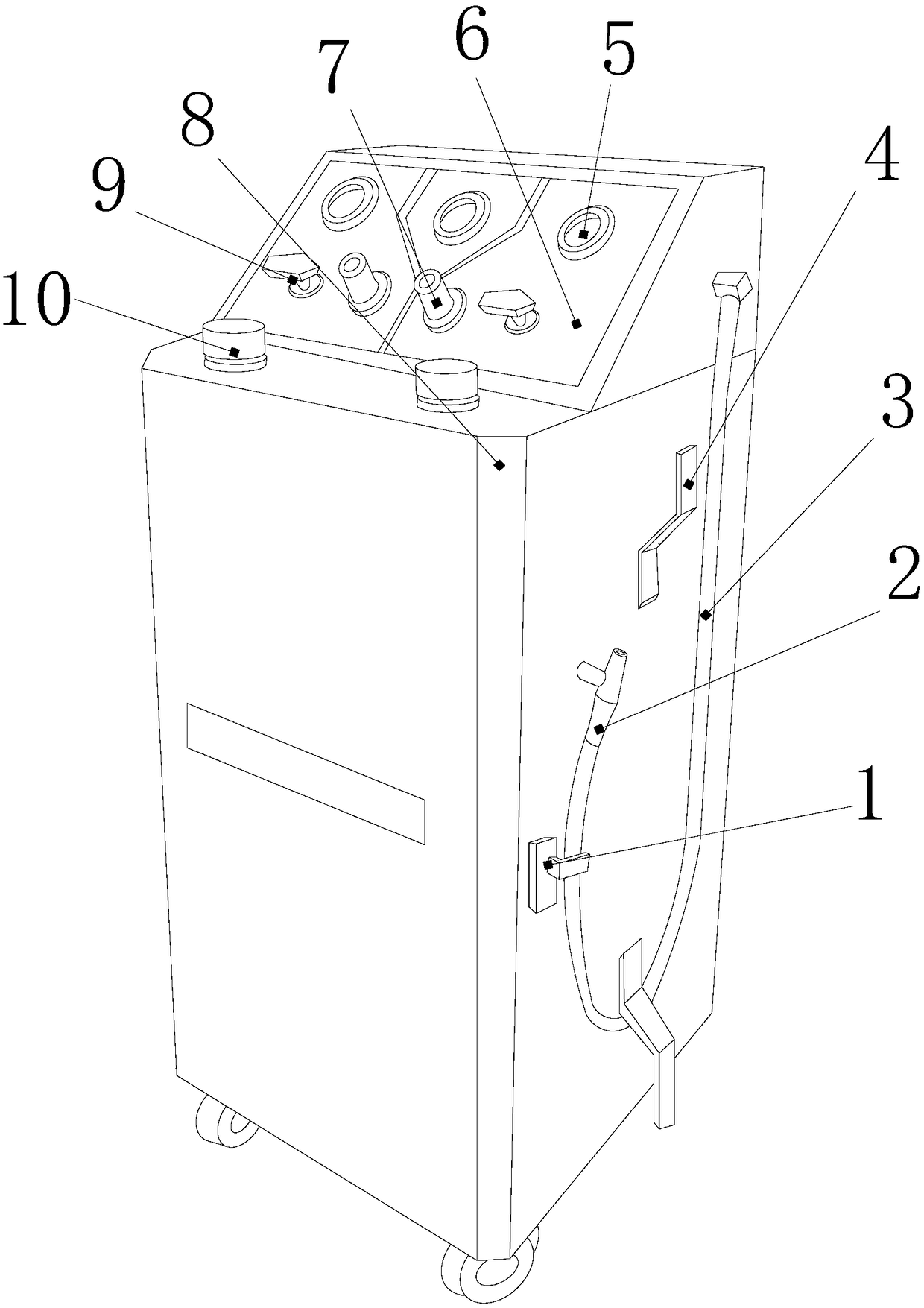

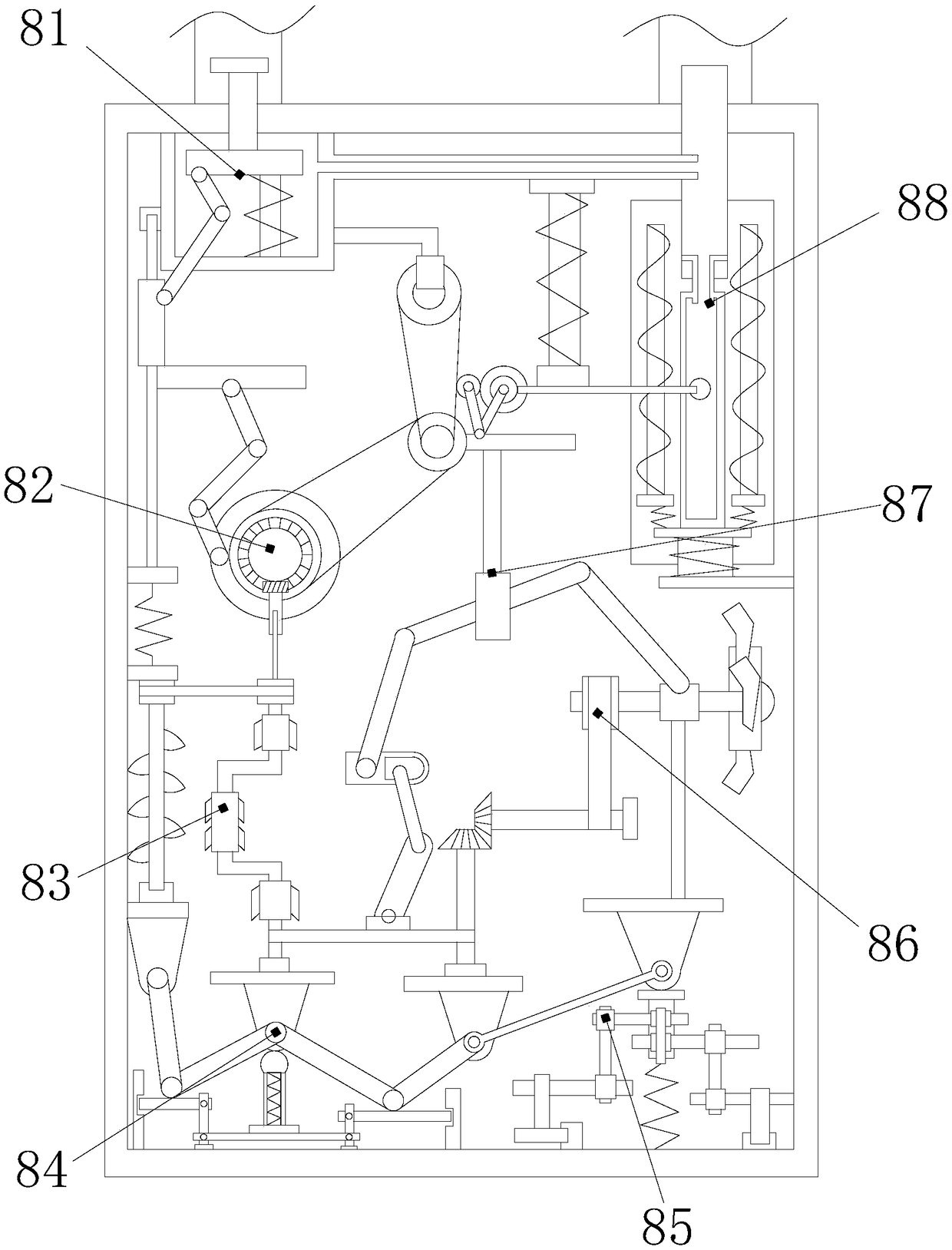

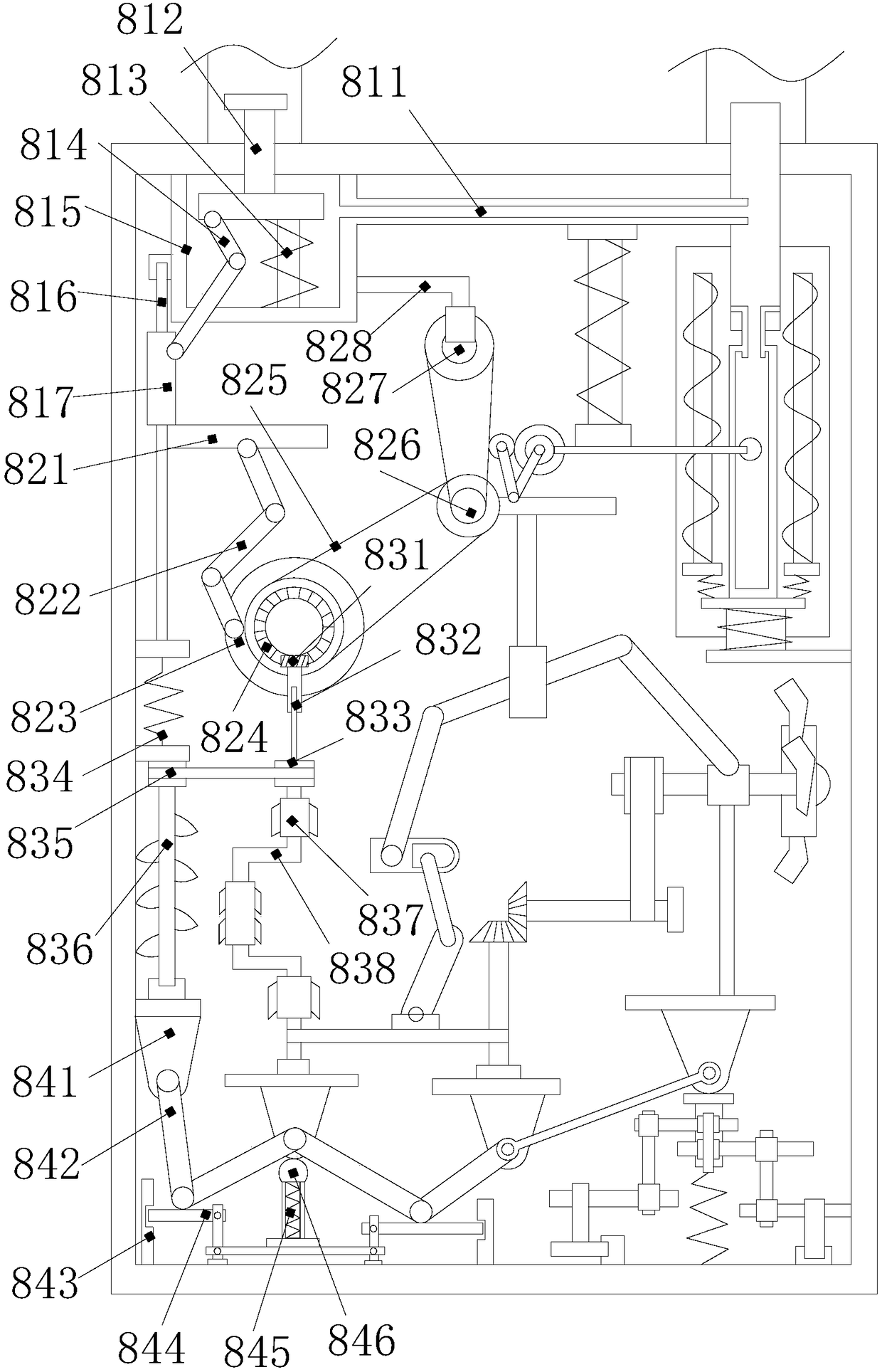

[0025] see Figure 1-Figure 5 , the present invention provides a kind of oil barrel cleaning equipment for petroleum refining, its structure includes: curved splint 1, water gun nozzle 2, water delivery conduit 3, Z-shaped hanging plate 4, pressure gauge 5, main control console 6, rocker Column cylinder 7, pumped tube type air compressor box 8, switch handle 9, adjustment knob 10, the top surface of the pumped tube type air compressor box 8 is closely attached to the bottom surface of the main control console 6 and communicates with each other. The pressure gauge 5 is nested on the front side of the main control console 6 at an angle of forty-five degrees. The rod cylinder 7 is inserted and embedded in the front side of the main control console 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com