A preparation method of biologically active filler comprising Brevibacterium nirbii

A technology of Brevibacterium neisseri and microbial activity is applied in the field of preparation of biologically active fillers, which can solve the problems of low volatile organic chlorine treatment efficiency, uneven loading, collapse of fillers, etc., achieving light weight, shortened start-up period, pressure small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 A microbial active filler for removing waste gas containing organic chlorine and its preparation

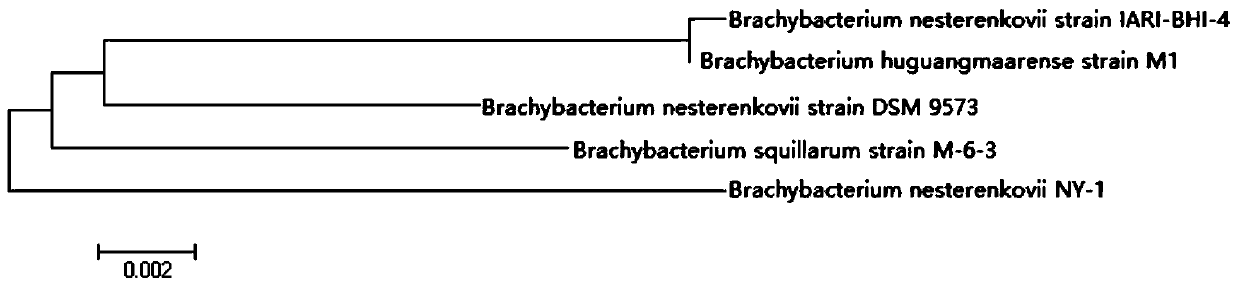

[0054] A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii (Brachybacteriumnesterenkovii) NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can better Treatment and purification of waste gas containing organic chlorine.

[0055] The filler is volcanic rock; the density of the filler is 900kg / m 3 , the porosity is 55%, the particle size is 4mm; the mass ratio of microbial suspension to filler is 2:10; the concentration of Brevibacterium NY-1 in microbial active filler is 2.5×10 7 CFU / g (填料) ;

[0056] The material of the hollow ball on the mesh surface is polyethylene; the hollow ball on the mesh surface has a diameter of 6 cm and is composed of two hemispheres, each hemisphere surface is porous, and the aperture of eac...

Embodiment 2

[0070] Example 2 A microbial filler for removing waste gas containing organic chlorine and its preparation

[0071]A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii (Brachybacteriumnesterenkovii) NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can better Treatment and purification of waste gas containing organic chlorine.

[0072] The filler is a polyurethane foam block; the filler density is 20kg / m 3 , the porosity is 90%, the particle size is 85mm; the mass ratio of the microbial suspension to the filler is 90:10; the concentration of Brevibacterium NY-1 in the microbial active filler is 1.0×10 10 CFU / g (填料) ;

[0073] The material of the hollow ball on the mesh surface is polypropylene; the hollow ball on the mesh surface has a diameter of 6 cm and is composed of two hemispheres, each hemisphere has a porous surface, and the ...

Embodiment 3

[0087] Example 3 A microbial filler for removing waste gas containing organic chlorine and its preparation

[0088] A kind of microbial active filler, described microbial active filler is prepared by the suspension of Brachybacterium nesterenkovii (Brachybacteriumnesterenkovii) NY-1 bacterial suspension being adsorbed on the filler, and the filler is packed in the mesh surface hollow ball, can better Treatment and purification of waste gas containing organic chlorine.

[0089] The filler is molecular sieve; the filler density is 500kg / m 3 , the porosity is 75%, the particle size is 50mm; the mass ratio of the microbial suspension to the filler is 50:10; the concentration of Brevibacterium NY-1 in the microbial active filler is 6.0×10 8 CFU / g (填料) ;

[0090] The material of the hollow ball on the mesh surface is polyvinyl chloride; the hollow ball on the mesh surface has a diameter of 6cm and is composed of two hemispheres, each hemisphere has a porous surface, and the apert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com