Ceramic material laser scribing process method

A ceramic material, laser scribing technology, used in stone processing equipment, laser welding equipment, stone processing tools, etc., can solve the problems of high local reflectivity, irregular fracture, uneven energy absorption, etc., to achieve good process stability , Improve the quality of product processing, the effect of good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of processing method of ceramic material laser scribing, comprises the following steps:

[0034] 1) Place the ceramic material to be processed on the adsorption platform of the fiber laser cutting machine and position it;

[0035] 2) Preset the cutting path and input the designed cutting path into the software;

[0036] 3) Set the laser processing parameters: in the state of positive focus position, the scribing speed is 200mm / s, the repetition frequency is 2800Hz, the pulse width is 0.1ms, and the peak power is 31.5W~45W when the power is 21%~30%;

[0037] 4) Start the fiber laser cutting machine, and laser scribe the ceramic material.

[0038] Such as Figure 1~4 As shown, the changes in the laser scribing depth of ceramic materials are as follows:

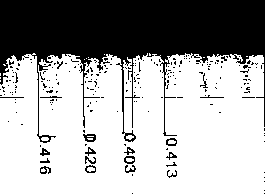

[0039] Such as figure 1 Shown: In step 3), when the peak power in the processing parameters is set to 21% power, that is, 31.5W, the obtained ceramic material laser scribing depth is 0.308mm, 0.3...

Embodiment 2

[0044] Embodiment 2: a kind of processing method of ceramic material laser scribing, comprises the following steps:

[0045] 1) Place the ceramic material to be processed on the adsorption platform of the fiber laser cutting machine and position it;

[0046] 2) Preset the cutting path and input the designed cutting path into the software;

[0047]3) Set the laser processing parameters: in the state of positive focus position, the scribing speed is 200mm / s, the pulse width is 0.1ms, the peak power is 39W, and the repetition frequency is 2400~2800Hz;

[0048] 4) Start the fiber laser cutting machine, and laser scribe the ceramic material.

[0049] Such as Figure 5~7 As shown, the changes in the laser scribing depth of ceramic materials are as follows:

[0050] Such as Figure 5 Shown: In step 3), when the repetition frequency in the processing parameters is 2400 Hz, the laser scribing depths of ceramic materials obtained are 0.335mm, 0.347mm, 0.337mm, 0.345mm, 0.349mm, 0.34...

Embodiment 3

[0054] Embodiment 3: a kind of processing method of ceramic material laser scribing, comprises the following steps:

[0055] 1) Place the ceramic material to be processed on the adsorption platform of the fiber laser cutting machine and position it;

[0056] 2) Preset the cutting path and input the designed cutting path into the software;

[0057] 3) Set the laser processing parameters: in the state of positive focus position, the scribing speed is 180~220mm / s, the pulse width is 0.1ms, the peak power is 39W, and the repetition frequency is 2400Hz;

[0058] 4) Start the fiber laser cutting machine, and laser scribe the ceramic material.

[0059] Such as Figure 8-10 As shown, the changes in the laser scribing depth of ceramic materials are as follows:

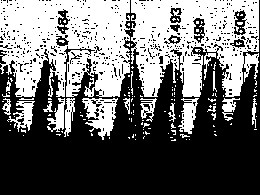

[0060] Such as Figure 8 Shown: In step 3), when the scribing speed in the processing parameters is 180 mm / s, the laser scribing depth of the obtained ceramic material is 0.490mm, 0.482mm, 0.490mm, 0.483mm, 0.480mm, etc.; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com