Superheated steam generating device and method of manufacturing conductor pipe used in the device

A technology for superheated steam and generating devices, which is applied in induction heating devices, manufacturing tools, coil devices, etc., and can solve problems such as breakage of joints and conductor tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

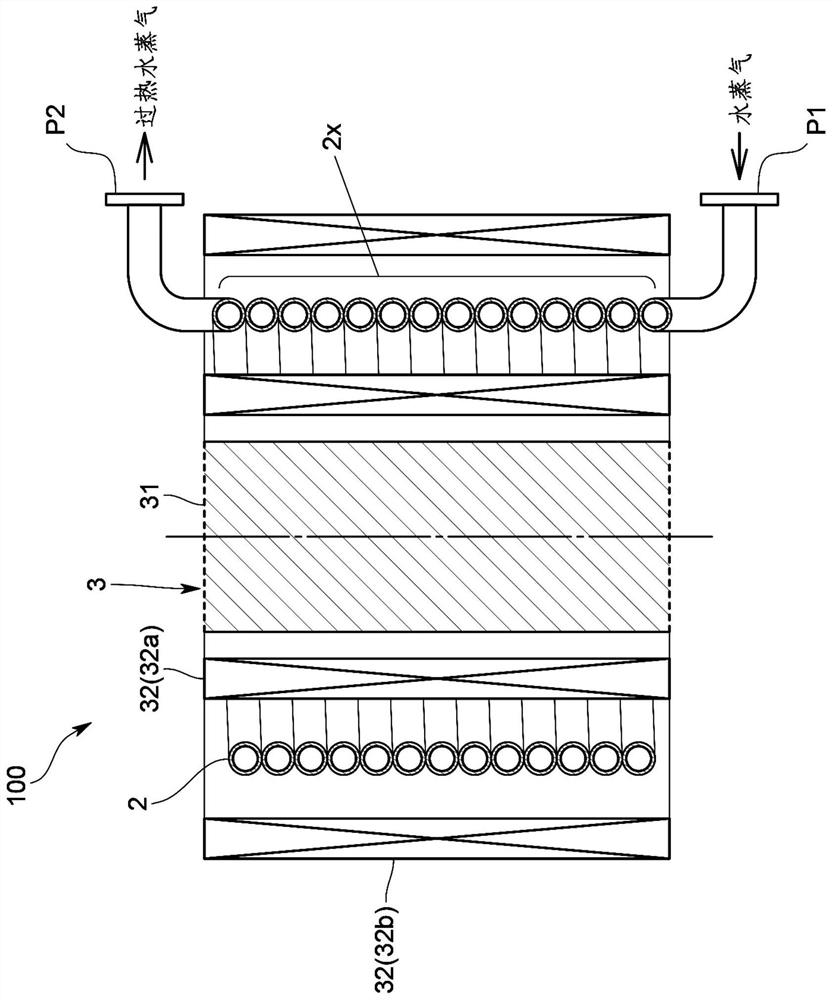

[0033] Hereinafter, one embodiment of the superheated steam generation device 100 of the present invention will be described with reference to the drawings.

[0034] Such as figure 1 As shown, the superheated steam generating device 100 generates superheated steam over 100°C (200°C-2000°C) by heating water or steam, and the superheated steam generating device 100 has a spirally wound circle A tubular conductor tube 2 and a magnetic flux generating mechanism 3 for inductively heating the conductor tube 2 .

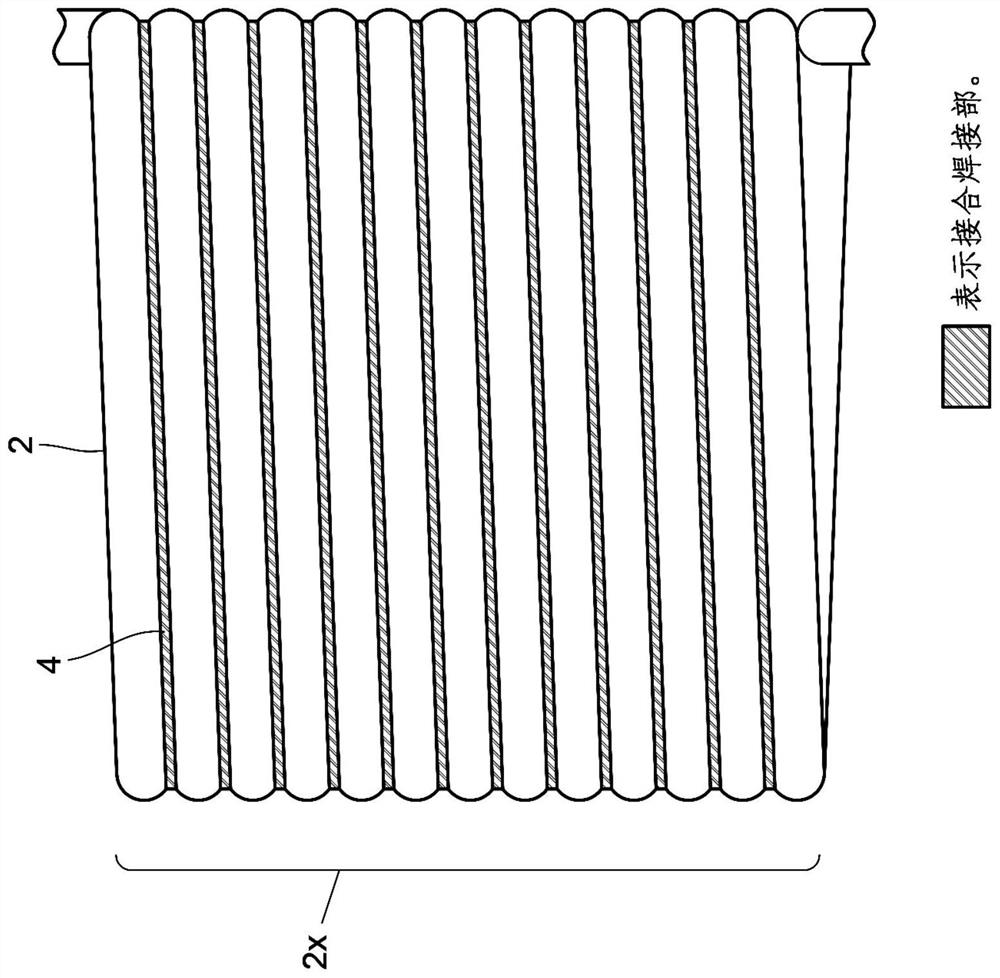

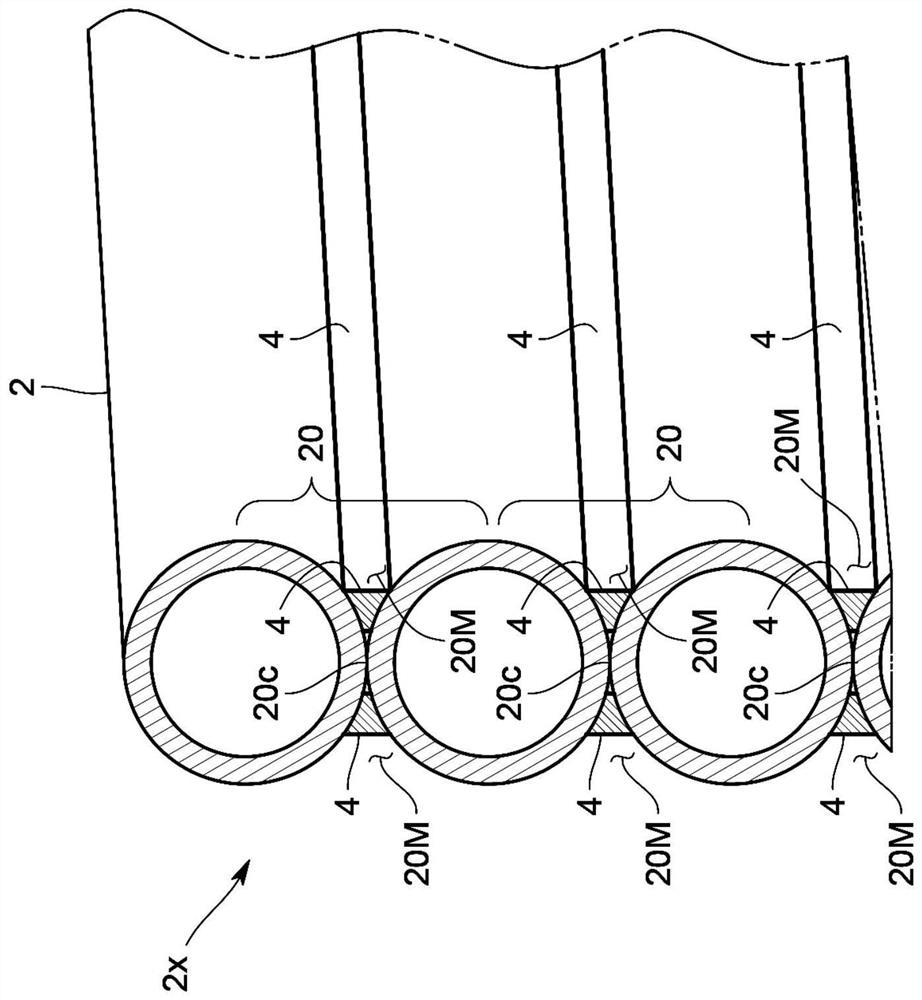

[0035] The conductor pipe 2 is formed of a metal pipe, has a helically wound winding portion 2x, and is formed at one end of the conductor pipe 2 with an inlet P1 for introducing water or steam, and at the other end with a The export port P2 which leads out the generated superheated steam. An external pipe for supplying water or steam to the conductor pipe 2 is connected to the inlet P1, and an external pipe for supplying the generated superheated steam to the use side (f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com