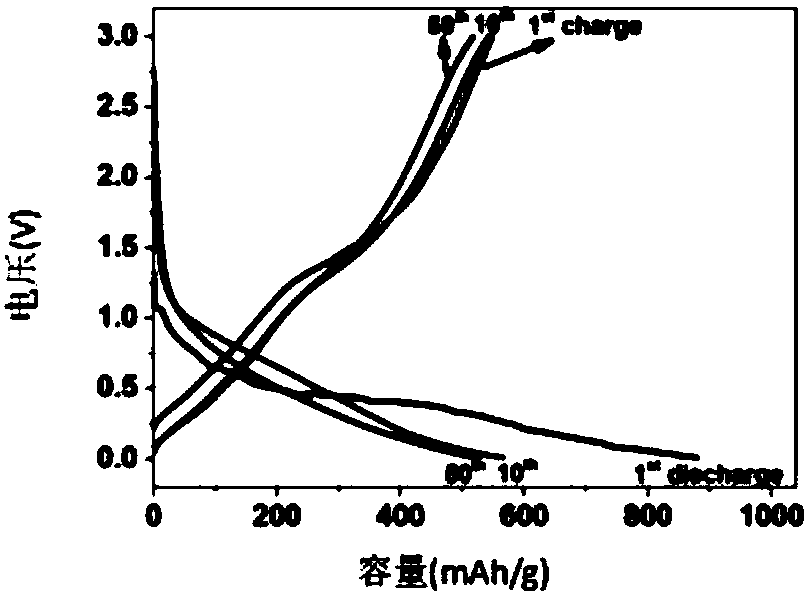

Preparation method of zinc oxide anode material for lithium ion secondary battery

A technology for negative electrode materials and secondary batteries, which is applied in the field of preparation of zinc oxide negative electrode materials for lithium-ion secondary batteries, can solve the problems of volume expansion change, poor conductivity, etc., and achieve buffer expansion effects, improve uniformity, and good rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for a zinc oxide negative electrode material for a lithium ion secondary battery, specifically comprising the following steps:

[0029] (1) Weigh 0.25mmol of zinc nitrate and 0.25mmol of 3,5-pyridinedicarboxylic acid, place them in a polytetrafluoroethylene reactor containing 15mL of deionized water, and stir thoroughly for 1 hour to mix the reaction materials evenly;

[0030] (2) Put the polytetrafluoroethylene reaction kettle in a blast drying oven, heat it at 100°C for 72 hours, and finally cool it with the furnace, then filter, wash and dry to obtain a zinc polymer single crystal dispersion;

[0031] (3) Transfer the zinc polymer single crystal dispersion to a microwave reactor, add 0.002 mmol of iron salt to the solution and stir for 2 hours until it is evenly stirred, then set the frequency of the microwave reaction to 50 MHz and react in the microwave Reaction in the kettle for 10 hours, finally standing for cooling, then filtering, washing a...

Embodiment 2

[0038] A preparation method for a zinc oxide negative electrode material for a lithium ion secondary battery, specifically comprising the following steps:

[0039] (1) Weigh 0.4mmol of zinc sulfate and 0.2mmol of 4-pyridinecarboxylic acid into a polytetrafluoroethylene reactor containing 18mL of dimethylformamide (DMF), and stir thoroughly for 10 hours to mix the reaction materials evenly ;

[0040] (2) Put the polytetrafluoroethylene reaction kettle in a blast drying oven, heat it at 200°C for 10 hours, and finally cool it with the furnace, then filter, wash and dry to obtain a zinc polymer single crystal dispersion;

[0041] (3) Transfer the zinc polymer single crystal dispersion to a microwave reactor, and add 0.003 mmol of copper salt to the solution and stir for 10 hours until it is evenly stirred, then set the frequency of the microwave reaction to 100MHz and Reaction in the reactor for 72 hours, and finally let it stand for cooling, then filter, wash and dry to obtain ...

Embodiment 3

[0044] A preparation method for a zinc oxide negative electrode material for a lithium ion secondary battery, specifically comprising the following steps:

[0045] (1) Weigh 0.3mmol of zinc sulfate and 0.1mmol of 3,3',5,5'-tetramethyl-4,4'-pyrazole in a polytetrafluoroethylene reactor containing 20ml of methanol , fully stirred for 1 hour, so that the reaction raw materials were mixed evenly;

[0046](2) Put the polytetrafluoroethylene reaction kettle in a blast drying oven, heat it at 180°C for 48 hours, and finally cool it with the furnace, then filter, wash and dry to obtain a zinc polymer single crystal dispersion;

[0047] (3) Transfer the zinc polymer single crystal dispersion to a microwave reactor, and add 0.002 mmol of cobalt salt to the solution and stir for 5 hours until it is evenly stirred, then set the microwave reaction frequency to 70MHz and React in the reactor for 48 hours, and finally let it stand for cooling, then filter, wash and dry to obtain the iron-zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com