MXene/bimetal oxide composite material, preparation method thereof and lithium ion battery negative electrode material

A bimetallic oxide, composite material technology, applied in battery electrodes, active material electrodes, negative electrodes, etc., to achieve the effects of easy control, strong interaction, good structural stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

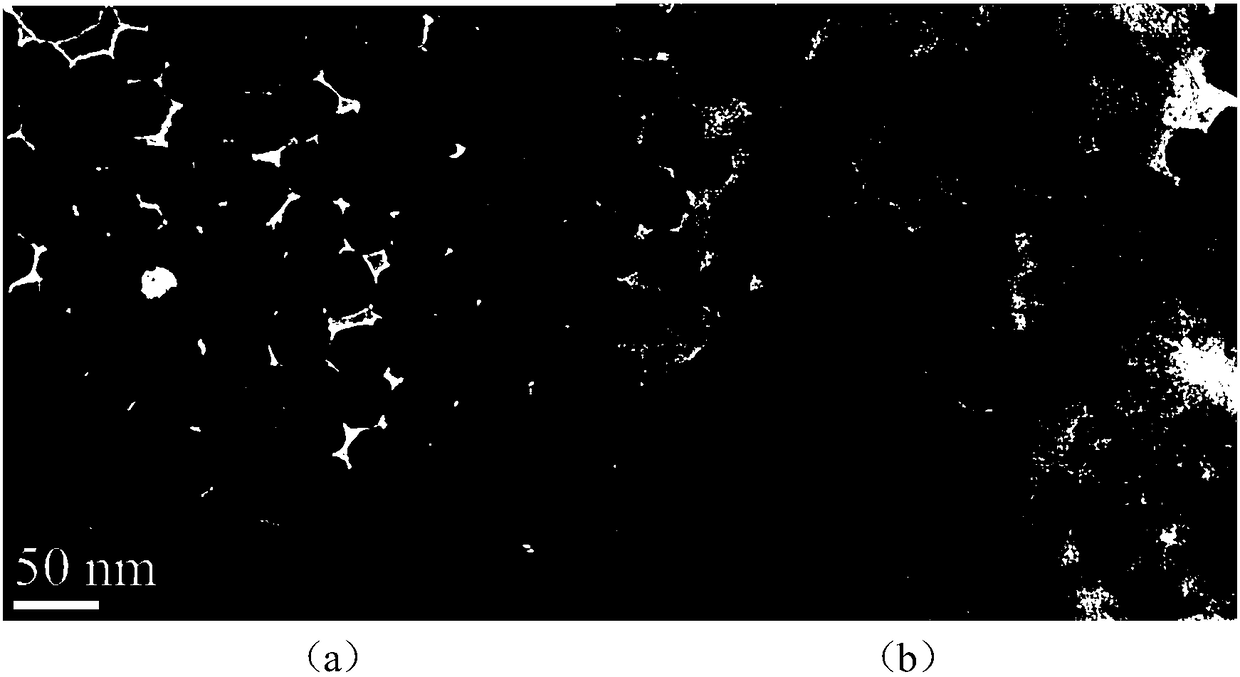

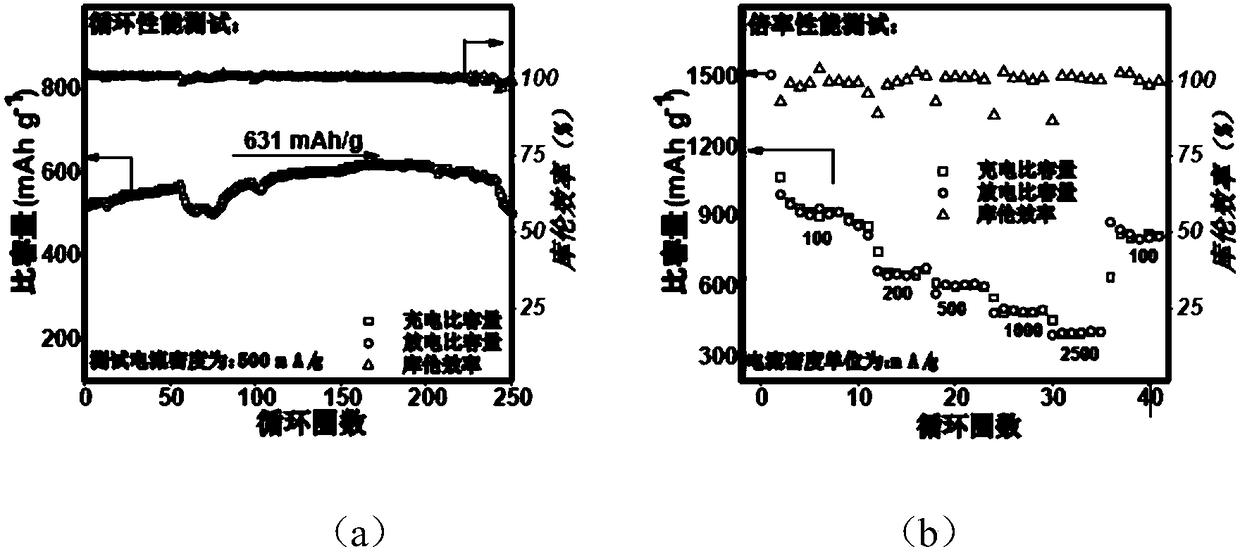

Image

Examples

preparation example Construction

[0032] The invention provides the preparation method of MXene / double metal oxide composite material, and this method comprises the steps:

[0033] (1) Preparation of a few-layer transition metal carbon / nitride (MXene) film: first prepare a powdery multilayer transition metal carbon / nitride, and then prepare a few-layer transition metal carbon / nitride film by vacuum filtration.

[0034] (2) Preparation of precursor solution:

[0035] Mix a few-layer transition metal carbon / nitride (MXene) film with acetylacetonate metal salt, and obtain a uniform mixed powder by grinding, add a bibenzyl ether solvent to dissolve and disperse the mixed powder, and add a surfactant, place Stir on a magnetic stirrer to obtain a reacted precursor solution;

[0036] (3) Synthesis of composite materials by in-situ pyrolysis method:

[0037] The obtained precursor solution was magnetically stirred, and N 2 Gas, set the flow rate of the gas, and the time of feeding the gas is 30 minutes to ensure th...

Embodiment 1

[0051] A preparation method for constructing a negative electrode material of a composite lithium-ion battery with transition metal carbon / nitride (MXene) and a double metal oxide, specifically comprising the following steps:

[0052] (1) Add 1g of lithium fluoride (LiF) powder to 20ml, 9mol / L hydrochloric acid (HCl) of hydrochloric acid (HCl), stir magnetically at 25°C, the rotation speed is 300r / min, and the stirring time is 20-30min. get a homogeneous mixture;

[0053] (2) Slowly add 1g of titanium aluminum carbon (Ti 3 AlC 2 ) raw materials, control the reaction temperature to rise to 35°C, continue to stir the reaction for 25 hours, and obtain the black multi-layer transition metal carbon / nitride (MXene) precipitate by centrifuging the solution obtained from the reaction at 5000 rpm, and alternately use ethanol and water Washing method Ultrasonic centrifugal washing to PH = 7, the rotation speed is 5000r / min, the time is 5min, the number of washings is 2-3 times, and th...

Embodiment 2

[0062] A preparation method for constructing a negative electrode material of a composite lithium-ion battery with transition metal carbon / nitride (MXene) and a double metal oxide, specifically comprising the following steps:

[0063] (1) Add 2g of lithium fluoride (LiF) powder to 40ml, 9mol / L hydrochloric acid (HCl) of hydrochloric acid (HCl), stir magnetically at 20°C, the speed is 300r / min, and the stirring time is 30min to obtain a uniform the mixture;

[0064] (2) Slowly add 2g of titanium aluminum carbon (Ti 3 AlC 2 ) raw materials, control the reaction temperature to rise to 35°C, continue to stir the reaction for 24 hours, and obtain the black multi-layer transition metal carbon / nitride (MXene) precipitate by centrifuging the solution obtained from the reaction at 5000 rpm, and alternately use ethanol and water Washing method Ultrasonic centrifugal washing to PH = 7, the rotation speed is 6000r / min, the time is 4min, the number of washings is 3 times, and the cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com