Titanium dioxide nanorod array film/cholesteric liquid crystal composite broadband reflecting film

A nanorod array and cholesteric liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as uneven dispersion, agglomeration of doped nanoparticles, unstable broadband reflection effect, etc., and achieve large birefringence The effect of widening the reflection wave width and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

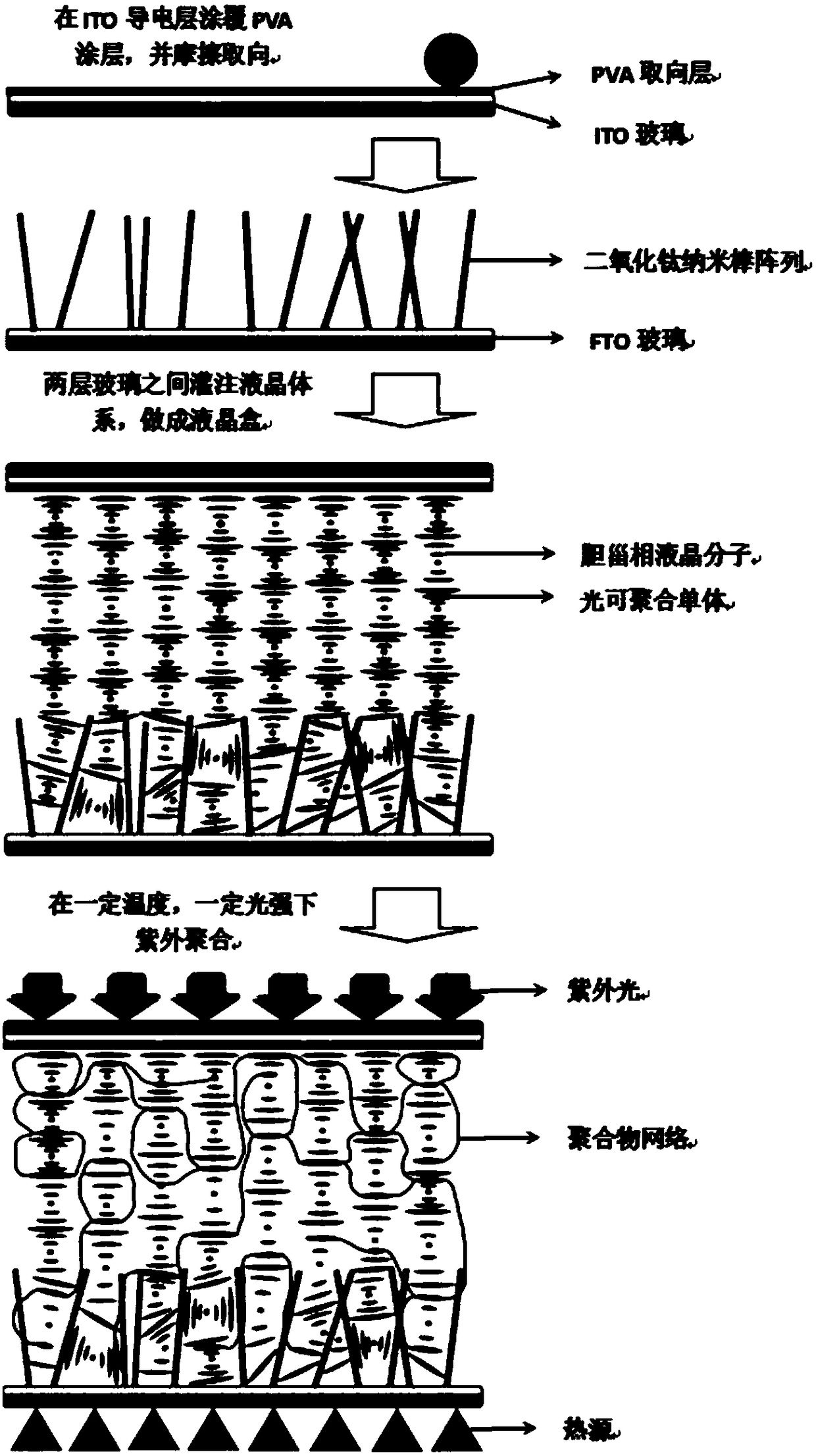

[0040] A titanium dioxide nanorod array film / cholesteric liquid crystal composite broad-wave reflective film, comprising an ITO conductive layer film or glass sequentially connected from top to bottom, a liquid crystal thin layer, an FTO conductive layer film or glass; the ITO conductive layer film Or coating insulating layer on glass; Synthesizing TiO on FTO conductive layer film or glass 2 Nanorod Array Films.

[0041] The ITO conductive layer film or glass and the FTO conductive layer film or glass control the thickness of the liquid crystal layer through a spacer, and the diameter of the spacer is 50 microns.

[0042] The preparation method of the titanium dioxide nanorod array film is as follows:

[0043] (1) Mix 10 kg of concentrated hydrochloric acid and 90 kg of deionized water, stir for 5 minutes, add 5 kg of sodium chloride, stir for 10 minutes to form a homogeneous solution, then add 4 kg of tetrabutyl titanate, and stir for 30 minutes.

[0044] (2) Put an FTO gla...

Embodiment 2

[0064] A titanium dioxide nanorod array film / cholesteric liquid crystal composite broad-wave reflective film, comprising an ITO conductive layer film or glass sequentially connected from top to bottom, a liquid crystal thin layer, an FTO conductive layer film or glass; the ITO conductive layer film Or coating insulating layer on glass; Synthesizing TiO on FTO conductive layer film or glass 2 Nanorod Array Films.

[0065] The ITO conductive layer film or glass and the FTO conductive layer film or glass control the thickness of the liquid crystal layer through a spacer, and the diameter of the spacer is 50 microns.

[0066] The preparation method of the titanium dioxide nanorod array film is as follows:

[0067] (1) Mix 90 kg of concentrated hydrochloric acid and 10 kg of deionized water, stir for 10 minutes, add 1 kg of sodium chloride, stir for 5 minutes to form a homogeneous solution, then add 0.4 kg of tetrabutyl titanate, and stir for 10 minutes.

[0068] (2) Put an FTO g...

Embodiment 3

[0087] A titanium dioxide nanorod array film / cholesteric liquid crystal composite broad-wave reflective film, comprising an ITO conductive layer film or glass sequentially connected from top to bottom, a liquid crystal thin layer, an FTO conductive layer film or glass; the ITO conductive layer film Or coating insulating layer on glass; Synthesizing TiO on FTO conductive layer film or glass 2 Nanorod Array Films.

[0088] The ITO conductive layer film or glass and the FTO conductive layer film or glass control the thickness of the liquid crystal layer through a spacer, and the diameter of the spacer is 50 microns.

[0089] The preparation method of the titanium dioxide nanorod array film is as follows:

[0090] (1) Mix 10 kg of concentrated hydrochloric acid and 90 kg of deionized water, stir for 5 minutes, add 5 kg of sodium chloride, stir for 10 minutes to form a homogeneous solution, then add 4 kg of tetrabutyl titanate, and stir for 30 minutes.

[0091] (2) The continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com