Terahertz polarization maintaining optical fiber and manufacturing method thereof

A technology for polarization-maintaining optical fiber and manufacturing method, which is applied in polarized optical fiber, cladding optical fiber, etc., and can solve problems such as weak wave binding ability and unfavorable wave stable transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below by way of examples.

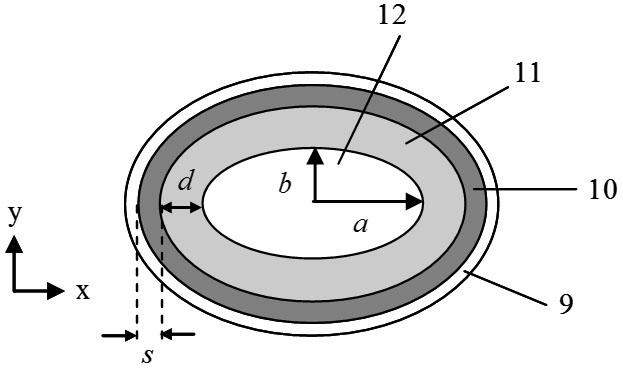

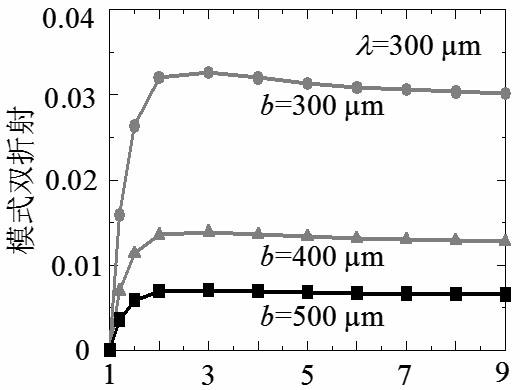

[0025] The target wavelength is 300 μm. The target parameters to be achieved by the fiber are: the mode birefringence is 2×10 -2 , the loss is 2-5 dB / m. First, an elliptical substrate tube is prepared according to the set optical fiber structure parameters. Then, using SnCl with a mass concentration of 0.1% 2 The aqueous solution activates the surface of the inner wall of the hollow-core optical fiber substrate tube, and through this step, the speed of the next step of silver film deposition can be accelerated and the surface roughness of the silver film can be reduced; A layer of silver film is coated on the inner wall of the tube; finally, a resin solution with a certain concentration is obtained by using cyclohexane as a solvent for the resin particles. A peristaltic pump is used to make the resin solution flow through the silver-coated optical fiber at a certain speed, and the remaining liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com