Display substrate and manufacturing method and display device thereof

A display substrate and a display device technology are applied in the fields of display devices, display substrates and manufacturing methods thereof, which can solve problems such as low yield rate, and achieve the effects of high yield rate, avoiding GDS phenomenon and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

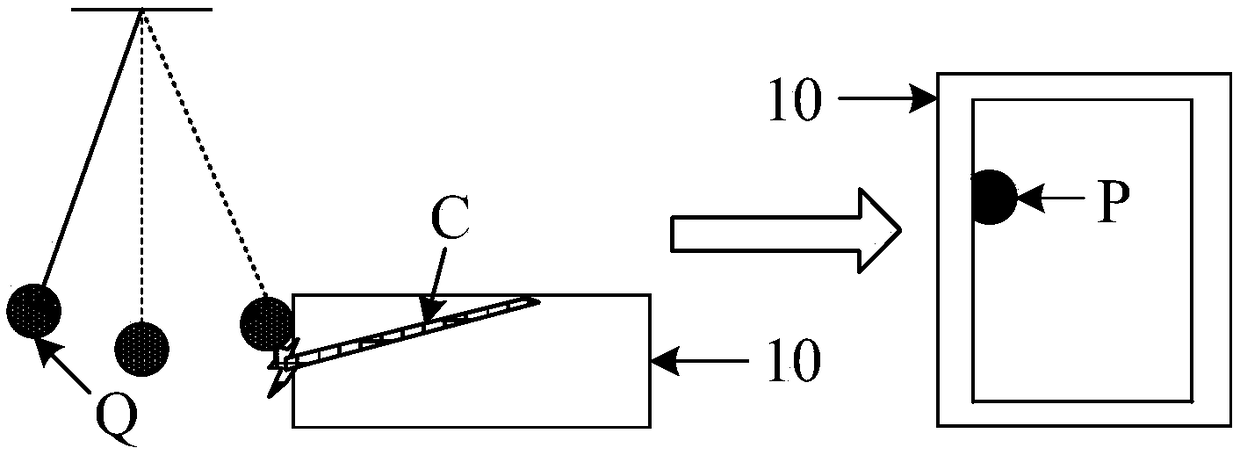

[0040] In order to ensure the yield rate of the display substrate when it leaves the factory, testers will conduct a series of performance tests on the display substrate after the display substrate is manufactured. figure 1 A schematic diagram is shown when a tester performs an impact test on a flexible display substrate. refer to figure 1 , when the tester hits the edge of the display substrate 10 with a ball Q, a crack C appears on the edge of the display substrate 10, and the crack C gradually extends to the packaging area of the display substrate 10, which may cause the packaging failure of the display substrate. At this time, water vapor or oxygen may intrude into the effective display area inside the display substrate 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com