A kind of lignin-filled foam slippers and preparation method thereof

A technology of lignin and slippers, applied in footwear, clothing, applications, etc., can solve the problems of poor comfort and hard materials, and achieve the effects of reducing plasticizer content, low equipment requirements, and stable cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

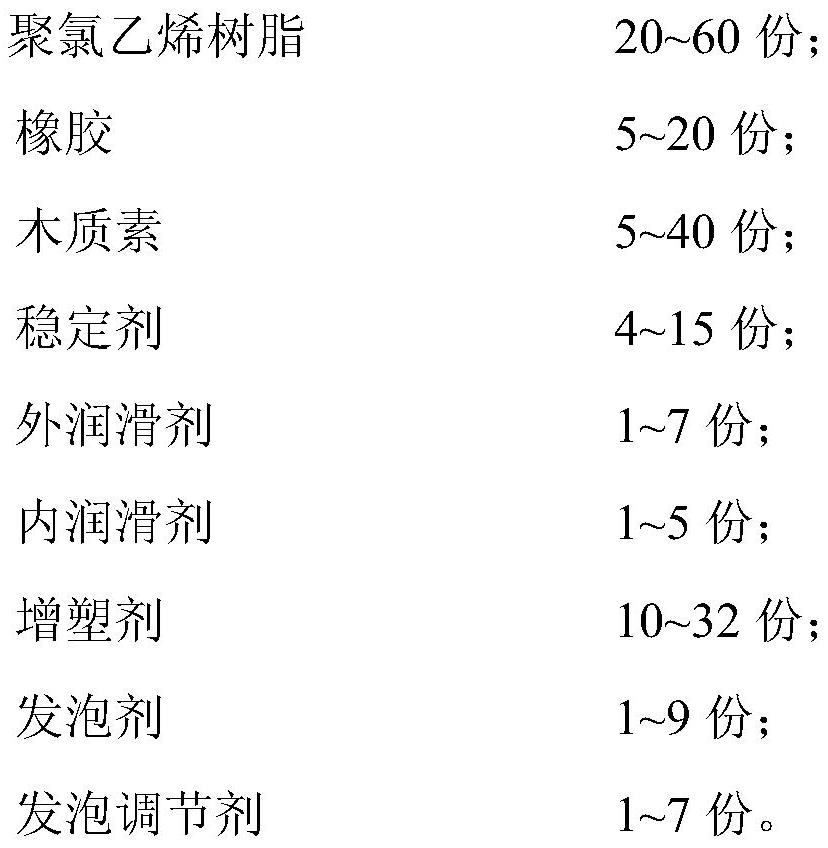

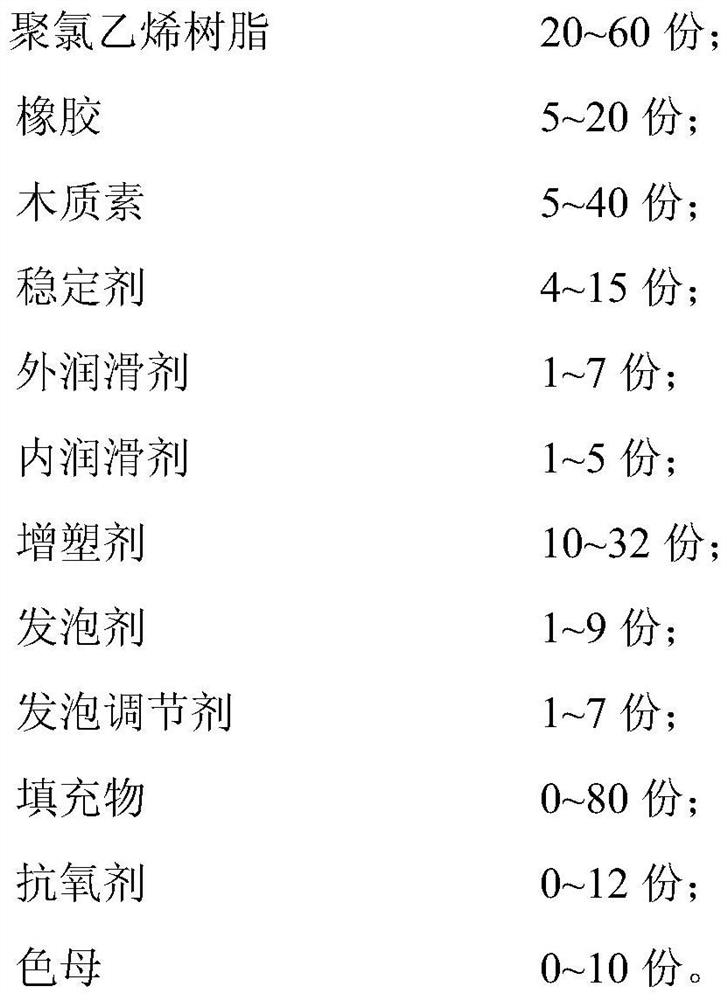

Method used

Image

Examples

Embodiment 1

[0034] A kind of foamed slipper filled with lignin and its preparation method:

[0035] 32 parts of polyvinyl chloride resin,

[0036] 8 parts neoprene,

[0037] Hardwood lignin 15 parts,

[0038] 6 parts of calcium zinc stabilizer,

[0039] 2 parts polyethylene wax,

[0040] 1 part stearic acid,

[0041] 20 parts of epoxy soybean oil,

[0042] AC blowing agent 1 part,

[0043] 1 copy of ACR,

[0044] 6 parts of talcum powder,

[0045] Antioxidant 1010 5 parts,

[0046] 3 copies of color masterbatch.

[0047] Its preparation method comprises the following steps:

[0048] (1) take each raw material according to parts by weight;

[0049] (2) First, polyvinyl chloride resin, lignin and other fillers and additives are added to the kneader, and kneaded at 95 ° C for 12 minutes;

[0050] (3) The kneaded material is injection-molded at 180° C. through a single-screw injection molding machine.

Embodiment 2

[0052] A kind of foamed slipper filled with lignin and its preparation method:

[0053] 27 parts of polyvinyl chloride resin,

[0054] 9 parts of natural rubber,

[0055] 18 parts of cork lignin,

[0056] 6 parts of calcium zinc stabilizer,

[0057] 2 parts polyethylene wax,

[0058] 1 part stearic acid,

[0059] 17 parts of tributyl citrate,

[0060] AC blowing agent 1 part,

[0061] 1 copy of ACR,

[0062] Calcium carbonate 10 parts

[0063] Antioxidant 1010 5 parts,

[0064] 3 copies of color masterbatch.

[0065] Its preparation method comprises the following steps:

[0066] (1) take each raw material according to parts by weight;

[0067] (2) First, polyvinyl chloride resin, lignin and other fillers and additives are added to the kneader, and kneaded at 105 ° C for 15 minutes;

[0068] (3) The kneaded material is injection-molded at 195° C. through a single-screw injection molding machine.

Embodiment 3

[0070] A kind of foamed slipper filled with lignin and its preparation method:

[0071] 27 parts of polyvinyl chloride resin,

[0072] Butadiene rubber 9 parts,

[0073] 21 parts of herbal lignin,

[0074] 6 parts of organotin stabilizer,

[0075] 2 parts polyethylene wax,

[0076] 1 part stearic acid,

[0077] Dioctyl phthalate 16 parts,

[0078] AC blowing agent 1 part,

[0079] 1 copy of ACR,

[0080] 8 parts of talcum powder,

[0081] Antioxidant 1010 5 parts,

[0082] 3 copies of color masterbatch.

[0083] Its preparation method comprises the following steps:

[0084] (1) take each raw material according to parts by weight;

[0085] (2) First, polyvinyl chloride resin, lignin and other fillers and additives are added to the kneader, and kneaded at 105 ° C for 15 minutes;

[0086] (3) The kneaded material is injection-molded at 200° C. through a single-screw injection molding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com