Preparation method of spaghetti with compact texture

A pasta and compact technology, applied in food science, food ultrasonic treatment, food ingredients as color, etc., can solve the problem of multiple cracks in pasta, and achieve the effect of attractive color, rich nutrition and attractive color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

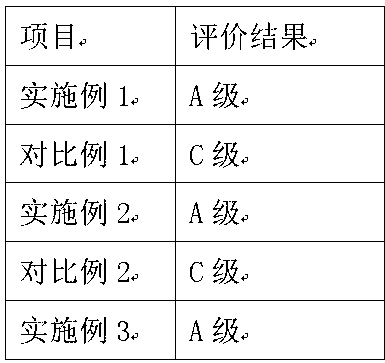

Examples

Embodiment 1

[0019] A method for preparing pasta with tight texture, comprising the following steps:

[0020] (1) After grinding quinoa into powder, add 2% of its weight vegetable oil to it, mix well, then add it into a stainless steel airtight container, raise the temperature in the stainless steel airtight container to 70°C, and keep it warm for 20 minutes. Take it out to make cooked quinoa flour;

[0021] (2) In parts by weight, mix 23 parts of cooked quinoa flour, 64 parts of durum wheat flour, 5 parts of white poria cocos dry powder, 4 parts of soybean protein isolate, and 0.1 part of sodium alginate, and then add 20 parts of water to it, After mixing evenly, the dough is made;

[0022] (3) Add the prepared dough to the extruder after ultrasonic treatment. When the extrusion enters the production stage and maintains stability, spray the treatment liquid evenly on the surface of the extruded noodles, and then stain the surface with The noodles of the treatment liquid are cut by a cut...

Embodiment 2

[0029] A method for preparing pasta with tight texture, comprising the following steps:

[0030] (1) After grinding quinoa into powder, add 3% of its weight vegetable oil to it, mix well, then add it into a stainless steel airtight container, raise the temperature in the stainless steel airtight container to 75°C, and keep it warm for 25 minutes. Take it out to make cooked quinoa flour;

[0031] (2) In parts by weight, mix 26 parts of cooked quinoa flour, 66 parts of durum wheat flour, 7 parts of white poria cocos dry powder, 5 parts of soybean protein isolate, and 0.1 part of sodium alginate, and then add 23 parts of water to it, After mixing evenly, the dough is made;

[0032] (3) Add the prepared dough to the extruder after ultrasonic treatment. When the extrusion enters the production stage and maintains stability, spray the treatment liquid evenly on the surface of the extruded noodles, and then stain the surface with The noodles of the treatment liquid are cut by a cut...

Embodiment 3

[0039] A method for preparing pasta with tight texture, comprising the following steps:

[0040] (1) After grinding quinoa into powder, add 4% of its weight vegetable oil to it, mix well, then add it into a stainless steel airtight container, raise the temperature in the stainless steel airtight container to 80°C, and keep it warm for 30 minutes. Take it out to make cooked quinoa flour;

[0041] (2) In parts by weight, after mixing 29 parts of cooked quinoa flour, 70 parts of durum wheat flour, 9 parts of white poria cocos dry powder, 6 parts of soybean protein isolate, and 0.2 part of sodium alginate, 25 parts of water were added thereto, After mixing evenly, the dough is made;

[0042] (3) Add the prepared dough to the extruder after ultrasonic treatment. When the extrusion enters the production stage and maintains stability, spray the treatment liquid evenly on the surface of the extruded noodles, and then stain the surface with The noodles of the treatment liquid are cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com