Natural rubber-neoprene composition material as well as preparation method and application thereof

A technology of natural rubber and chloroprene rubber, applied in the field of natural rubber-chloroprene rubber composite materials, can solve problems such as fatigue durability life and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

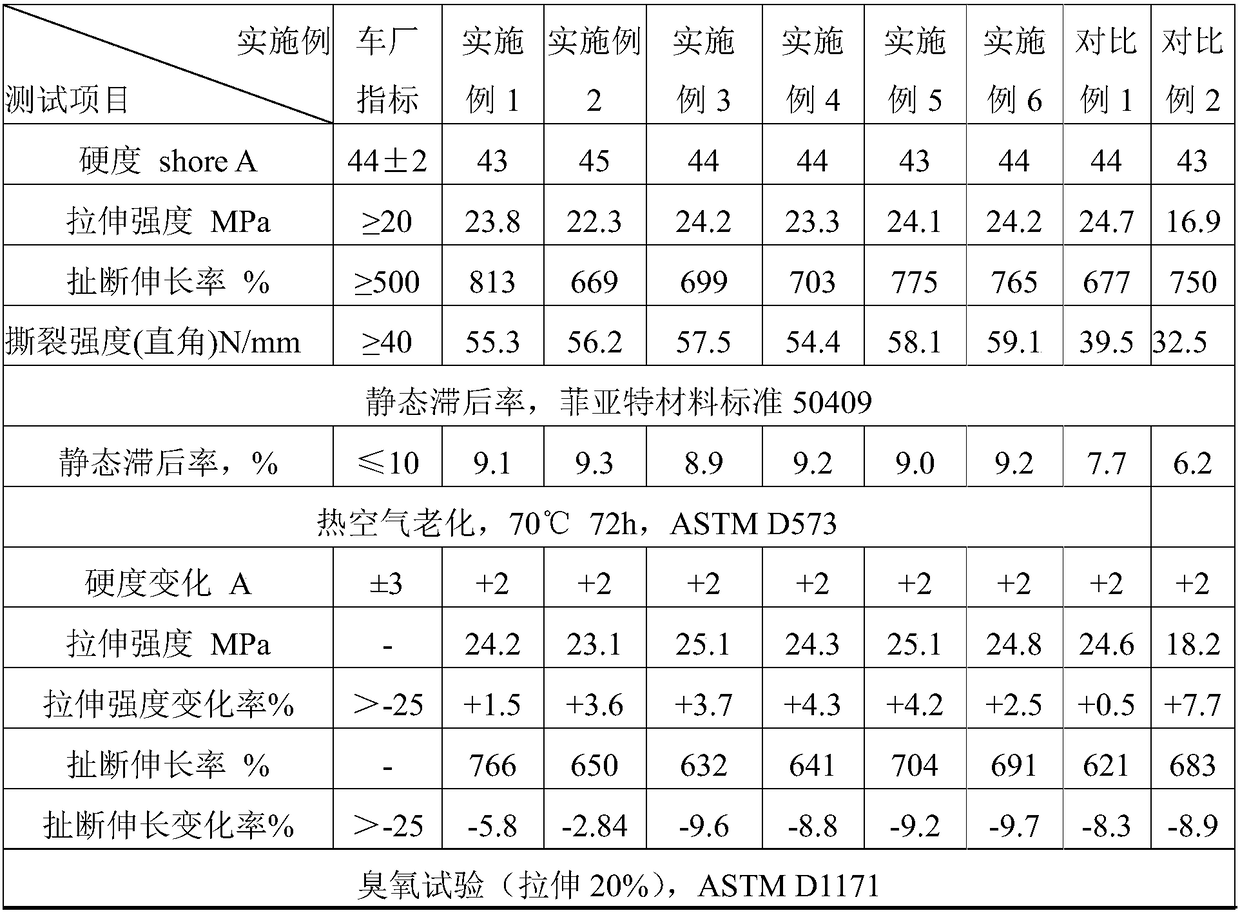

Examples

Embodiment 1~6、 comparative example 1 and comparative example 2

[0095] Among them, BR9000 in Comparative Example 2 is butadiene rubber of the type BR9000 produced by the Sichuan Plant of China Petrochemical Corporation.

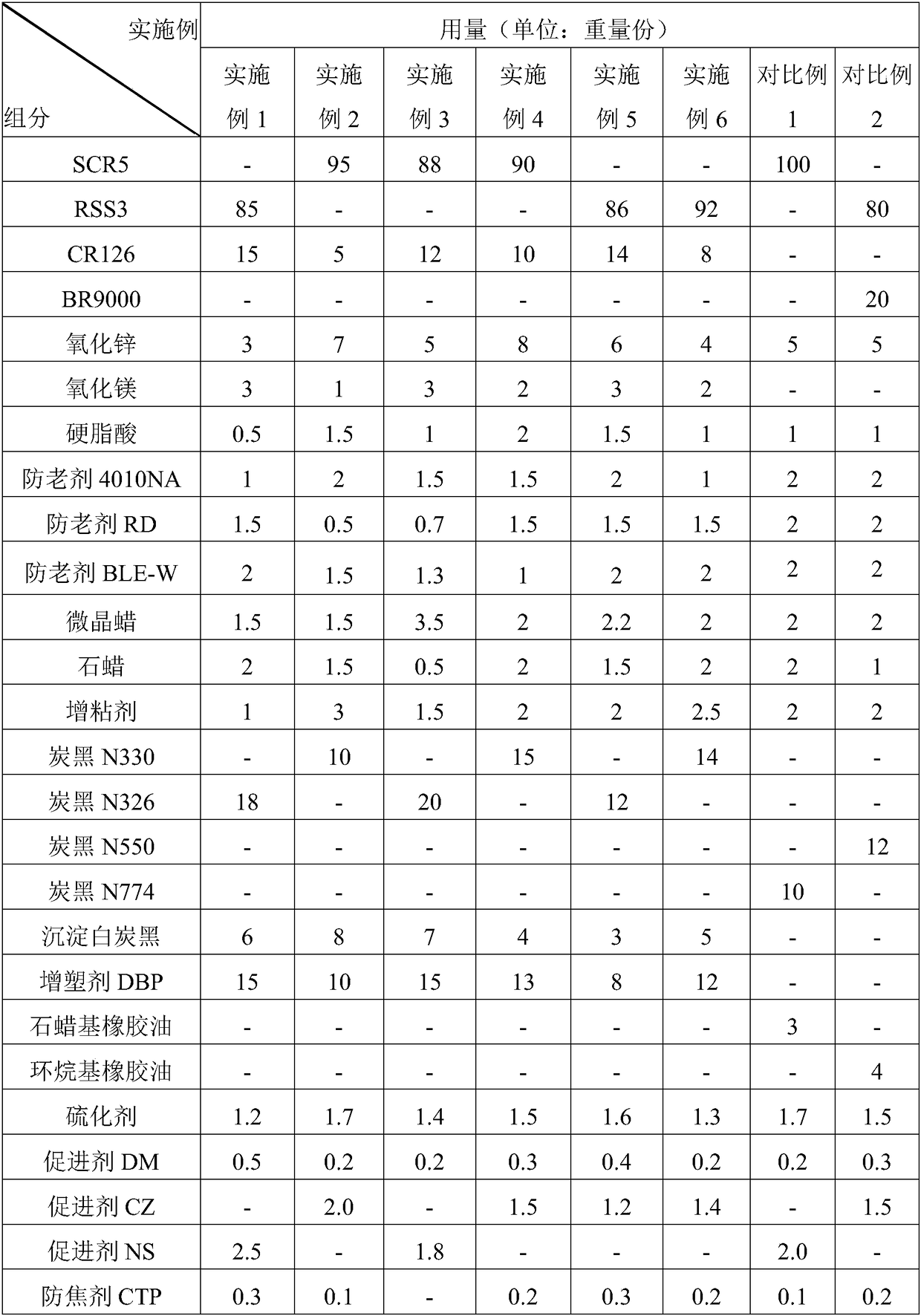

[0096] Table 1

[0097]

[0098] "-" in Table 1 indicates that the dosage is "0".

Embodiment 1~6

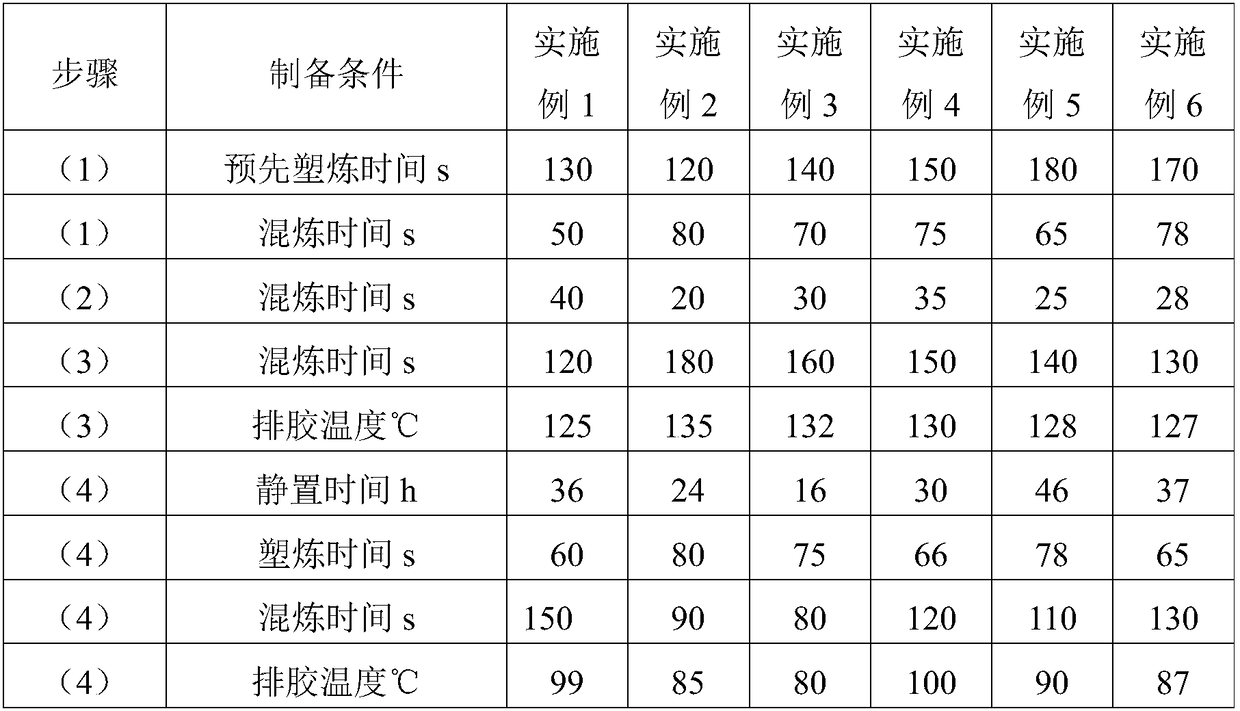

[0100] Embodiments 1 to 6, the raw material components of each embodiment in Table 1 are obtained according to the following preparation steps to obtain the product of each embodiment (the parameters of each step are as shown in Table 2):

[0101] (1) Pre-plasticize the natural rubber with a internal mixer, and use the open mixer to produce a sheet with a thickness of 3mm, and use it within 4-12 hours; mix the natural rubber and neoprene with an internal mixer to obtain a mixture A ;

[0102] (2) Continue to input activator zinc oxide, magnesium oxide, stearic acid, anti-aging agent, protective wax, tackifier mixing to internal mixer, get mixture B;

[0103] (3) Continue to drop into the internal mixer carbon black, precipitated silica, and plasticizer for mixing, then carry out glue removal and sheet discharge to obtain rubber premix;

[0104] (4) Put the rubber premixed rubber to rest, then put the rubber premixed rubber after standing still into the internal mixer for mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com