High-strength high-toughness X100 pipeline steel hot-rolled steel strip and manufacturing method thereof

A manufacturing method and high-toughness technology, applied in metal rolling and other directions, can solve problems such as the content limitation of Ca and O elements, achieve the effects of improving the shape of inclusions and refining the size, good strength and toughness matching, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

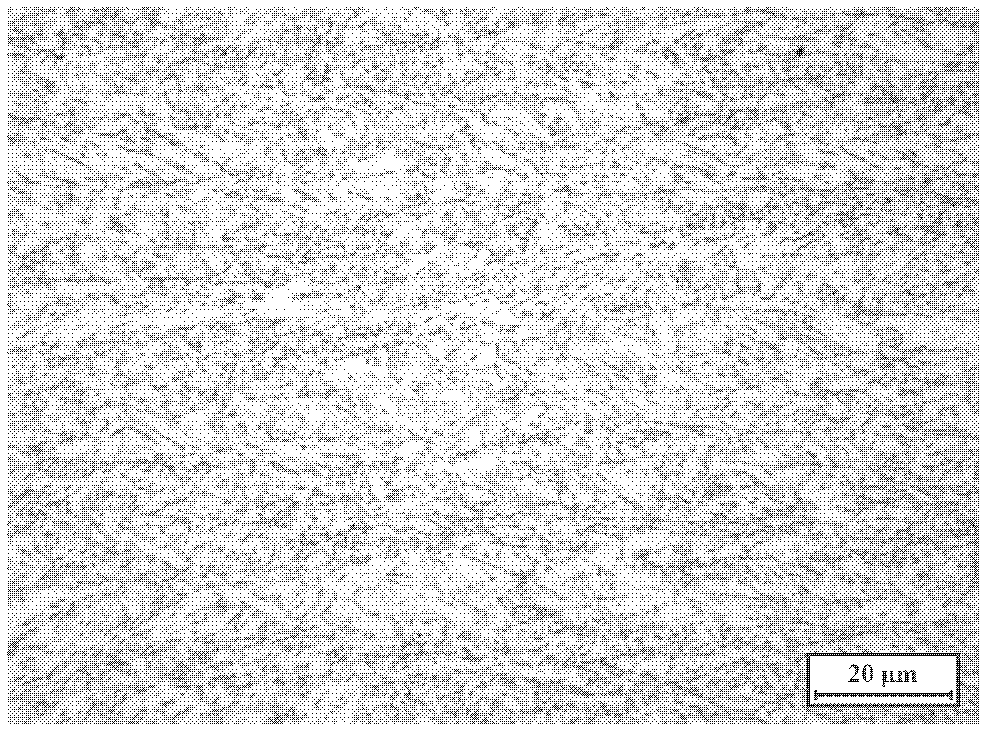

Image

Examples

Embodiment 1-7

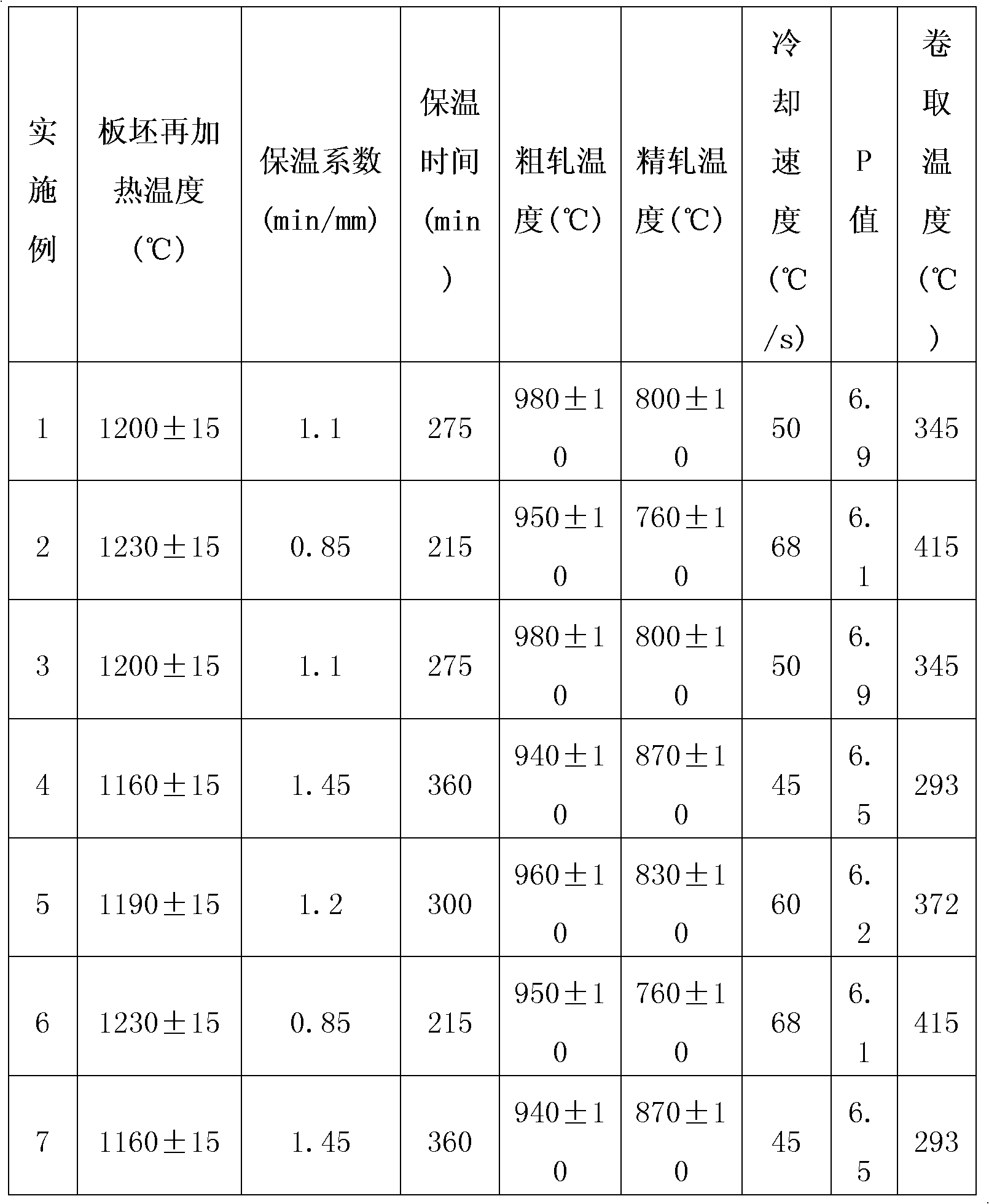

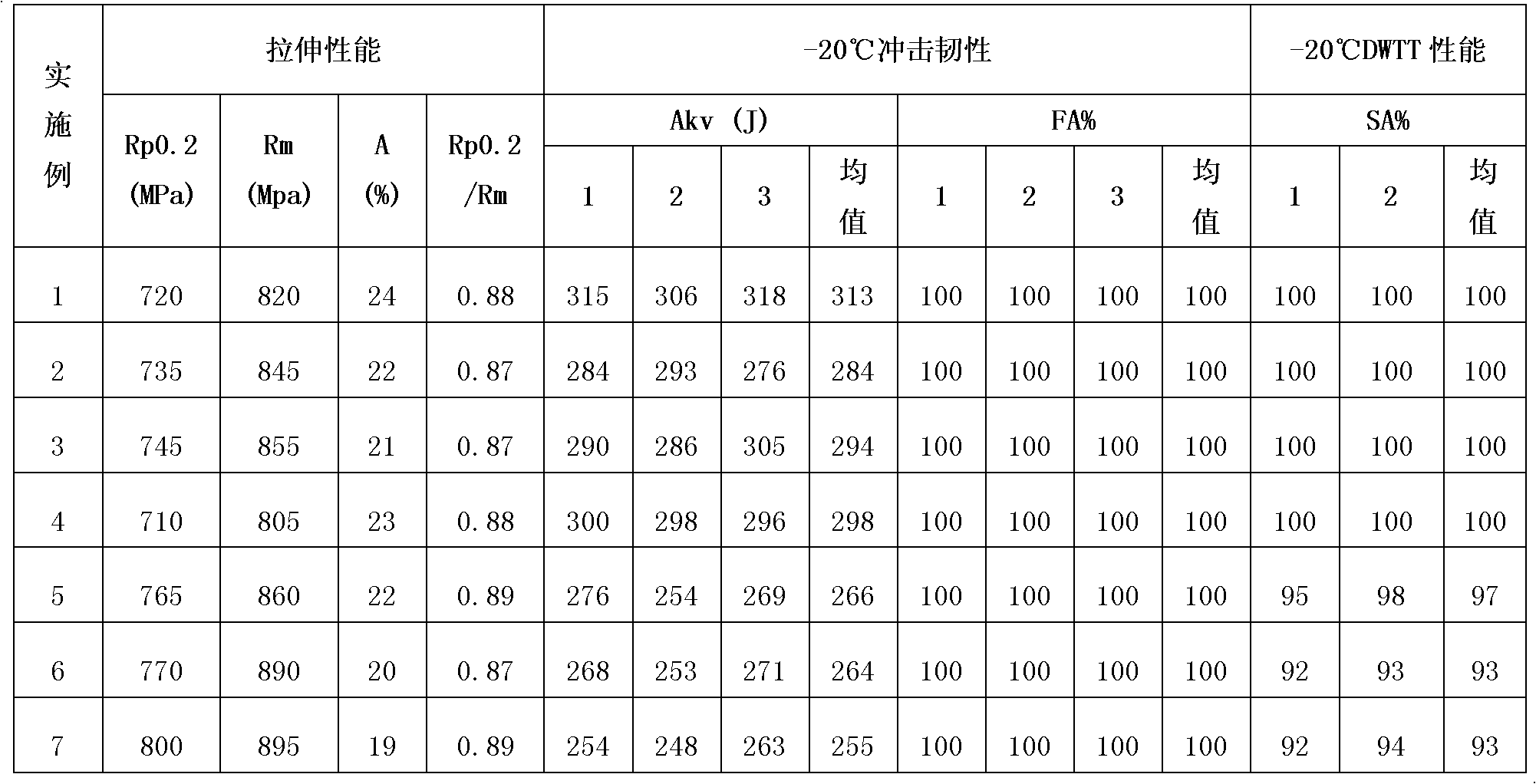

[0041] Manufacture the high-strength and high-toughness X100 pipeline steel hot-rolled strip of the present invention according to the following steps (see Table 1 for the chemical element ratio of each steel strip in Embodiment 1-7, and see Table 1 for detailed process parameters in Embodiment 1-7. Table 2):

[0042] (1) Electric furnace or converter smelting raw materials;

[0043] (2) Continuous casting;

[0044] (3) Reheat the slab, the heating temperature is 1145-1250°C, the thickness of the slab is 250mm, the holding time is determined according to the thickness of the slab and the heat preservation coefficient, and the heat preservation coefficient is 0.8-1.50min / mm;

[0045] (4) Rough rolling: the rough rolling temperature is 930-1000°C;

[0046] (5) Finish rolling: the finish rolling temperature is 750-900°C;

[0047] (6) Controlled cooling: the cooling rate is 41-70°C / s;

[0048] (7) Coiling; the coiling temperature is determined according to the cooling rate in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com