Novel gear hobbing machine

A gear hobbing machine, a new type of technology, applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of time-consuming and laborious workpiece clamping, labor-intensive labor, manual operation, etc., to reduce damage, high clamping efficiency, and reduce The effect of slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

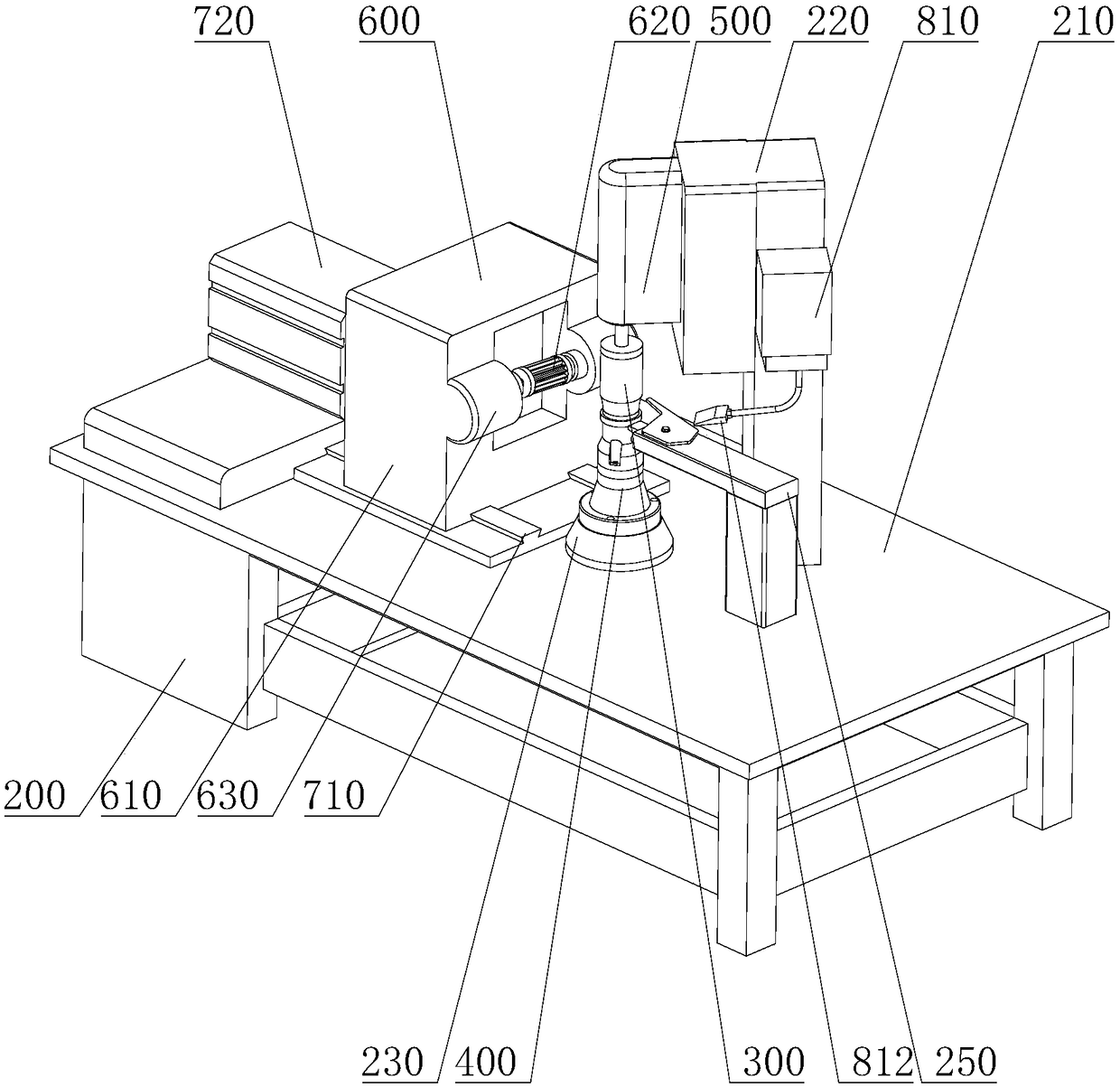

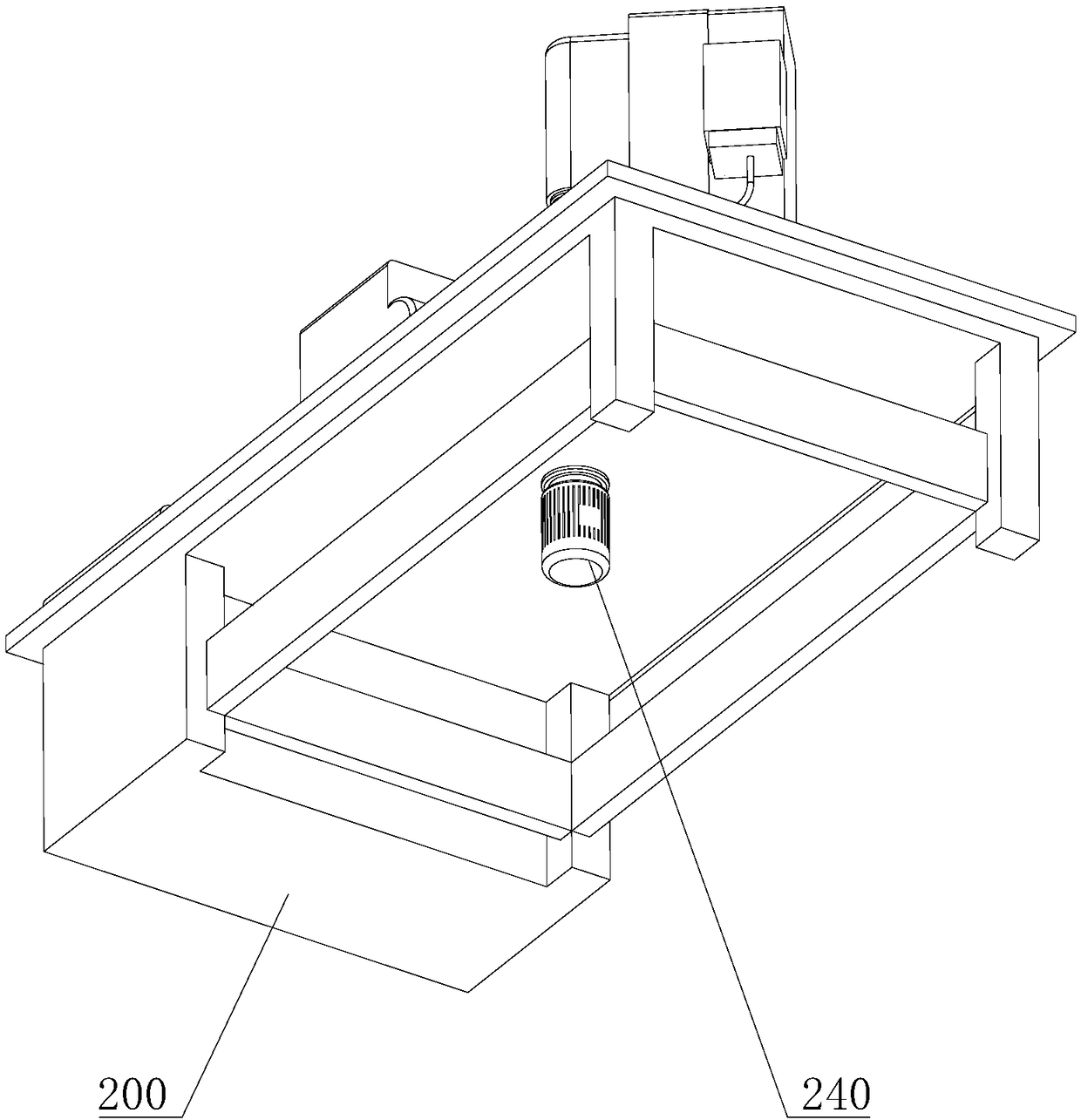

[0040] See attached figure 1 And attached figure 2 , a new gear hobbing machine, including a protective case 100 and a frame 200 partially arranged in the protective case 100 . The frame 200 includes an installation platform 210 arranged at the inner bottom of the protective case 100. The installation platform 210 is provided with a clamping device, a gear hobbing device 600 on one side of the clamping device, and a driving gear hobbing device 600 that slides reciprocally along the direction of the clamping device. Shifting slide components.

[0041] The hobbing device 600 includes a hobbing frame 610 , a hob 620 rotatably mounted on the hobbing frame 610 , and a hobbing motor 630 driving the hob 620 to rotate. Under the action of the sliding component, the gear hobbing device 600 slides towards the clamping device, and the hobbing motor 630 drives the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com