Hierarchical pore molecular sieve N-Meso-ZSM-5 catalyst, and method for preparing bio-oil through catalytic pyrolysis of lignin by catalyst

A molecular sieve, multi-level pore technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long residence time, difficult reaction conditions, difficult catalyst recovery, etc., to reduce equipment investment. , the effect of alleviating energy and environmental problems, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

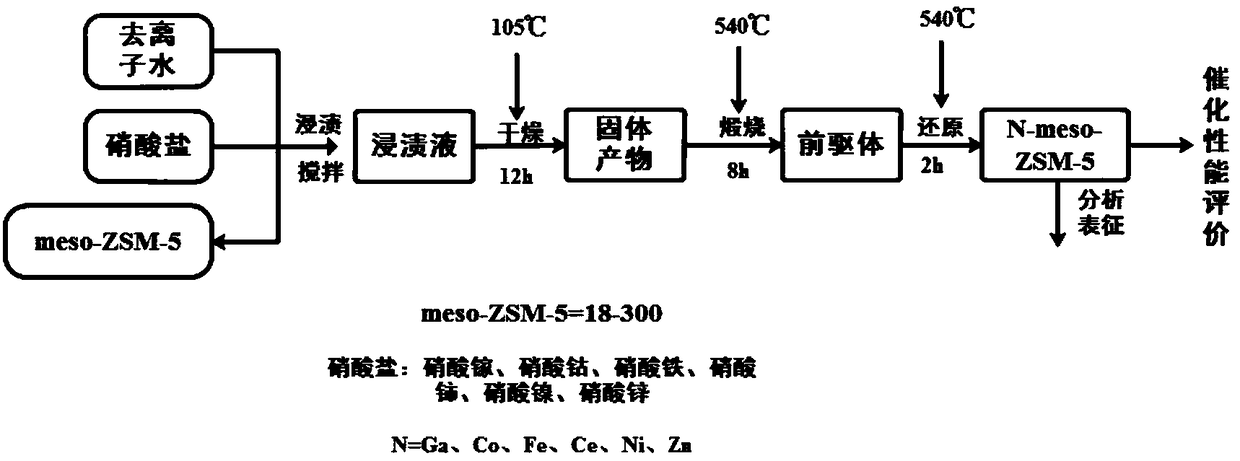

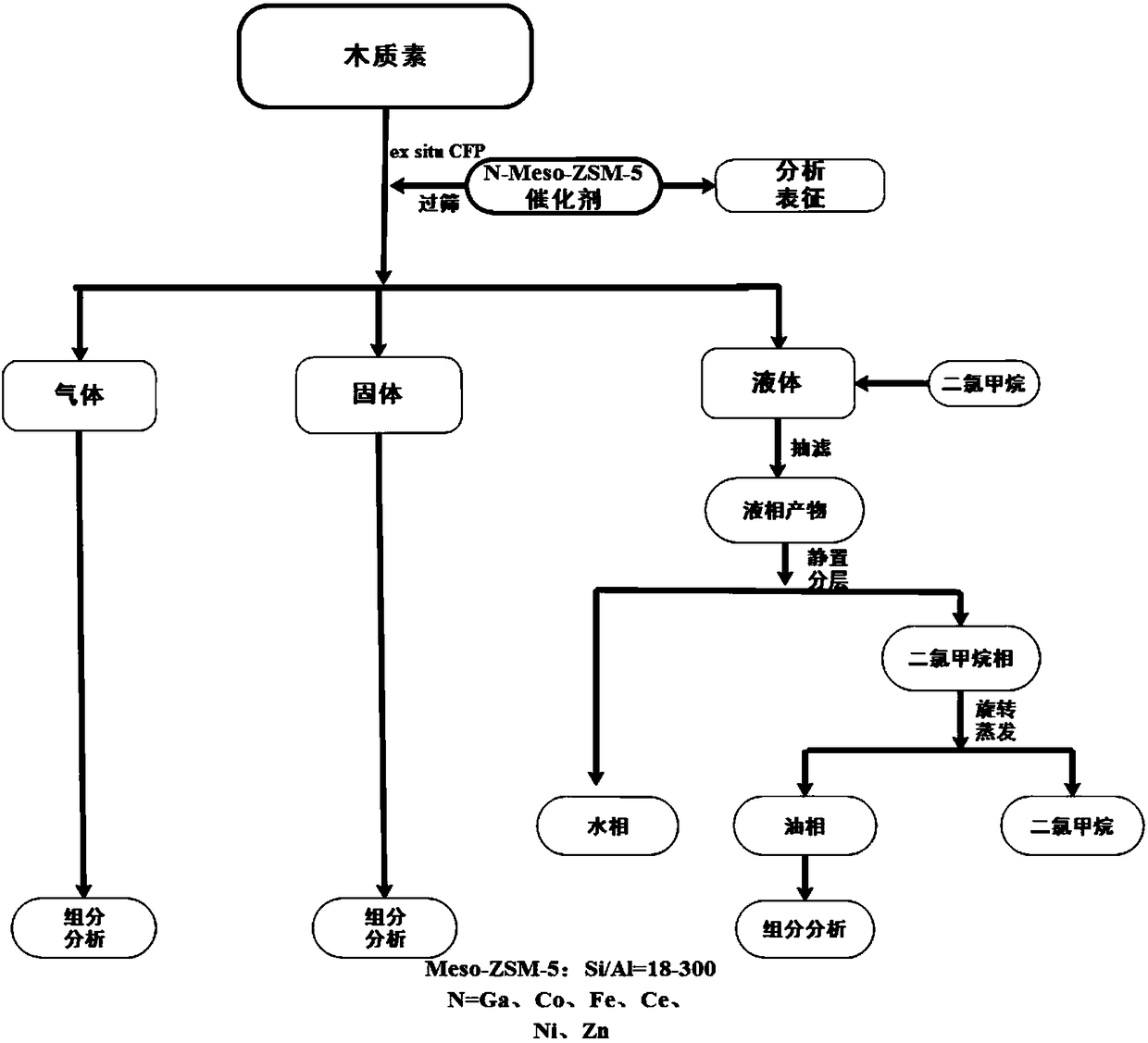

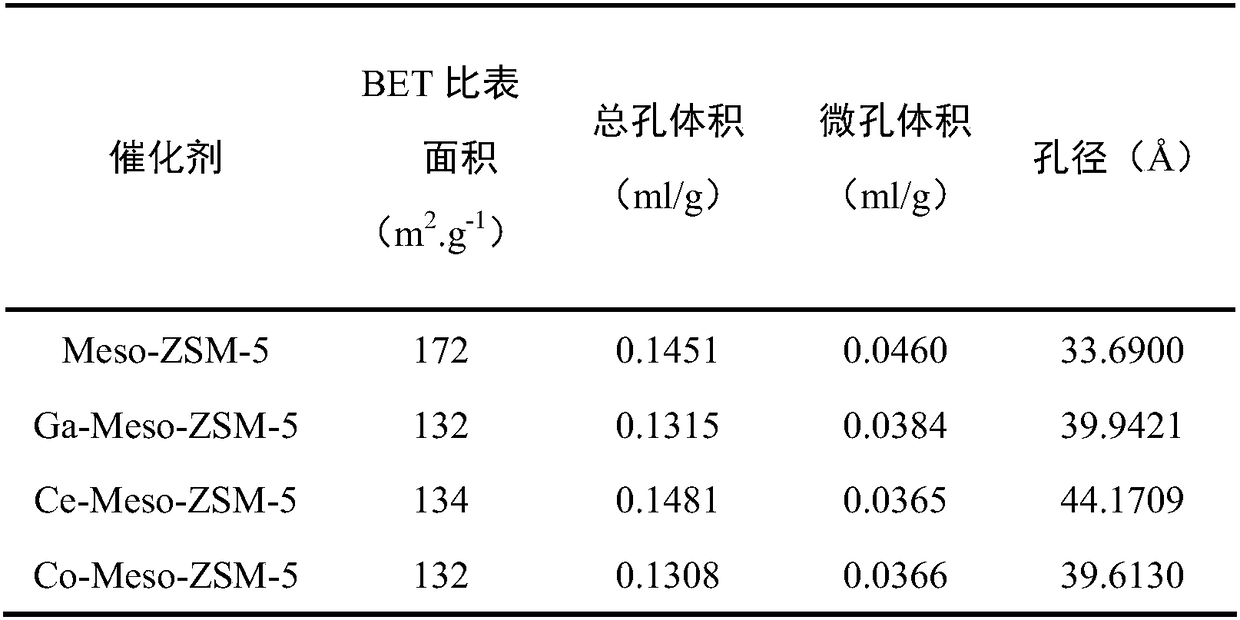

Method used

Image

Examples

Embodiment 1

[0036] Weigh 10g lignin sample and 1g catalyst into the reactor according to the material-liquid ratio of 10:1. The addition amount of the catalyst is 10% of the lignin. The multi-stage porous catalyst is selected as Ga-Meso-ZSM-5 for pyrolysis. The temperature is 500°C; the catalytic temperature is 600°C; the pressure is normal pressure; the reaction time is 4h, and the liquid yield is 7.00%. The relative content of total phenolic compounds such as phenol, guaiacol, hydroquinone and catechol in the catalytic conversion products is 96.15%.

Embodiment 2

[0038] Weigh 10g lignin sample and 1g catalyst according to the material-liquid ratio of 10:1 and add them to the reactor. The addition amount of the catalyst is 10% of the lignin. The multi-stage porous catalyst is Co-Meso-ZSM-5, and the pyrolysis The temperature is 500°C; the catalytic temperature is 600°C; the pressure is normal pressure; the reaction time is 4h, and the liquid yield is 8.70%. The relative content of total phenolic compounds such as phenol, guaiacol, hydroquinone, and catechol in the catalytic conversion product is 96.26%.

Embodiment 3

[0040] Weigh 10g lignin sample and 1g catalyst according to the material-to-liquid ratio of 10:1 and add them to the reactor. The addition amount of the catalyst is 10% of the lignin. The multi-stage porous catalyst is Ce-Meso-ZSM-5, which is used for pyrolysis. The temperature is 500°C; the catalytic temperature is 600°C; the pressure is normal pressure; the reaction time is 4h, and the liquid yield is 10.39%. The relative content of total phenolic compounds such as phenol, guaiacol, hydroquinone, and catechol in the catalytic conversion products is 97.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com