Seawater desalination de-foaming agent as well as preparation method and application thereof

A defoamer and emulsifier technology, applied in the field of seawater desalination defoamer and its preparation, can solve the problems of high cost of use, poor foam suppression ability, low foam breaking rate, etc., to achieve non-corrosive, easy to operate, stable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051]In view of the need to improve the environmental performance and use efficiency of the current defoamer, the present invention provides a high-efficiency seawater desalination defoamer and its preparation method and application.

[0052] In a preferred embodiment, the high-efficiency seawater desalination defoamer of the present invention includes the components described in Table 1:

[0053] Table 1 Seawater desalination defoamer components

[0054] silicone paste

5~20%

Polyether modified silicone

10~30%

Emulsifier

2~10%

thickener

0.5~2%

0.01~0.05%

water

margin

The total proportion of each component

100%

[0055] The preparation method of the silicone paste comprises: adding simethicone, gas-phase silicon dioxide, and a catalyst into a reaction kettle in proportion, and reacting at 100-150° C. for 4-6 hours to prepare the silicone paste. Further, the viscosity of the simethicone oil...

Embodiment 1

[0074] 1.1 Preparation of silicone paste

[0075] A total of 35 g of simethicone, fumed silica, and catalyst (KOH solution, concentration: 4 wt%) were added into the reaction kettle in proportion, and reacted at 100° C. for 6 hours to prepare a silicone paste. Wherein, the viscosity of the simethicone oil is 500mPa·s; the fumed silica is a hydrophobic fumed silica with a specific surface area of 400mPa. 2 / g; the mass ratio of the three components is simethicone:fumed silica:catalyst=97.5:2:0.5.

[0076] 1.2 Preparation of polyether modified silicone

[0077] Add 0.05 g of 2,4-di-tert-butyl p-cresol to 56 g of allyl alcohol polyether toluene solution (the concentration of allyl alcohol polyether is 82.14%), and add isopropanol-dissolved chloroplatinum under nitrogen atmosphere Acid solution catalyst (the concentration of chloroplatinic acid is 1%), chloroplatinic acid accounts for 40 μg / g of the total reactants; start stirring, and slowly add low hydrogen-containing silico...

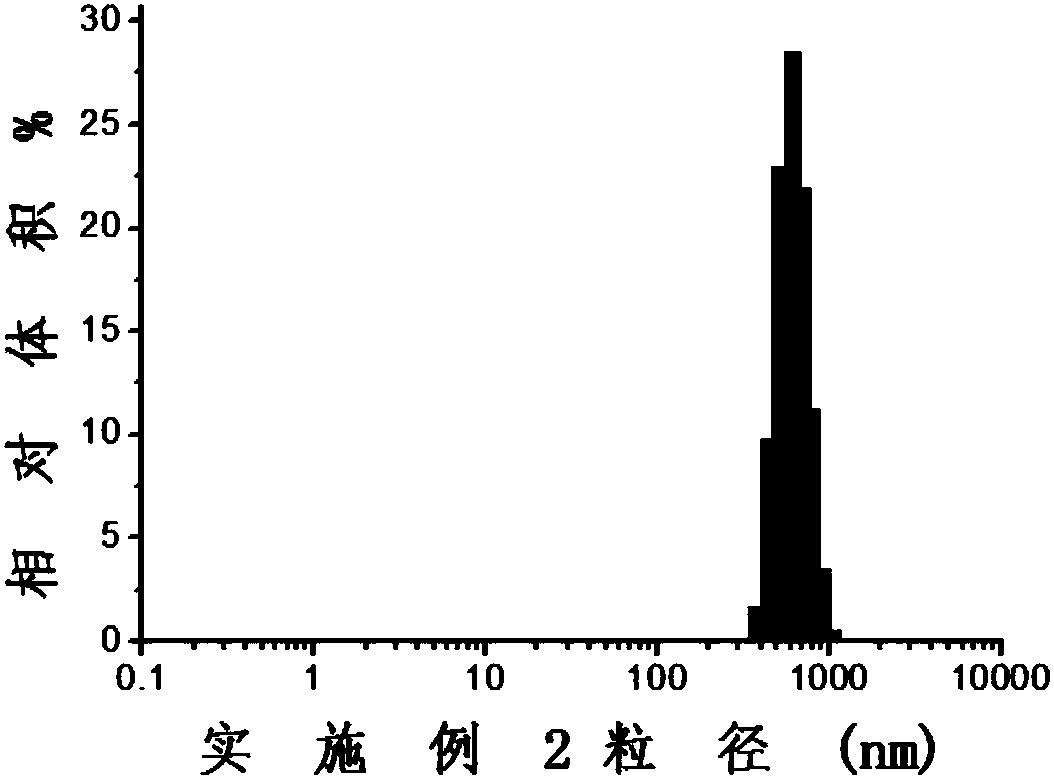

Embodiment 2

[0085] 2.1 Preparation of silicone paste

[0086] A total of 70 g of simethicone, fumed silica, and catalyst (KOH solution, concentration: 2 wt%) were added to the reaction kettle in proportion, and reacted at 150° C. for 4 hours to prepare a silicone paste. Wherein, the viscosity of the simethicone oil is 1000mPa·s; the fumed silica is a hydrophobic fumed silica with a specific surface area of 200mPa. 2 / g; the mass ratio of the three components is simethicone:fumed silica:catalyst=93:5:2.

[0087] 2.2 Preparation of polyether modified silicone

[0088] Add 0.03g hydroquinone in the allyl alcohol polyether isopropanol solution (the concentration of allyl alcohol polyether is 70.59%) in 34g, add the chloroplatinic acid solution catalyst (chloroplatinum chloride) that isopropanol dissolves under nitrogen protection acid concentration is 1%), chloroplatinic acid accounted for 20 μg / g of the total reactant; start stirring, slowly add low hydrogen-containing silicone oil, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com