An analgesic and sleeping aid capsule and its preparation method

A sleep aid and capsule technology, which is applied in capsule delivery, medical formula, non-central analgesics, etc., can solve the problems of treating the symptoms but not the root cause, and increasing the dosage of melatonin, so as to relieve pain, obtain materials easily, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

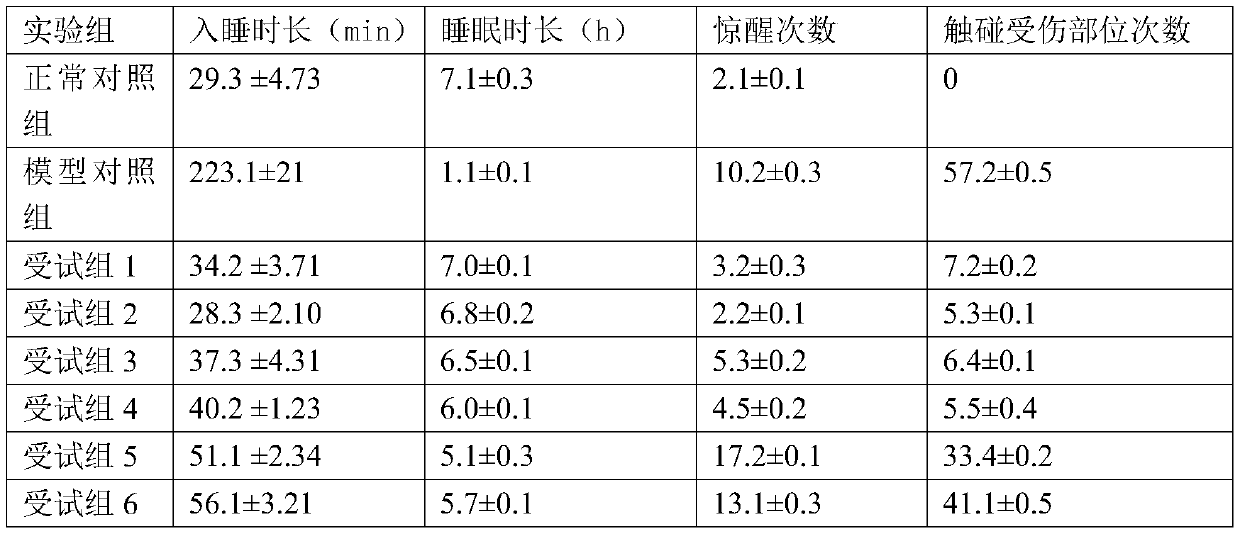

Examples

Embodiment 1

[0021] Embodiment 1: capsule preparation

[0022] Take 300g of phoenix clothes and add 20 times the mass of water, extract at 100°C for 4h, then centrifuge at 3500r / min for 25min, take the supernatant, add 8 times the mass of water to the filter residue, extract at 100°C for 1h, and then Centrifuge at 3500r / min for 25min, take the supernatant, combine the two filtrates to obtain a mixed extract; place the mixed extract in a rotary evaporator at 70°C, evaporate and concentrate to 1 / 10 of the volume of the original mixed extract; Add trypsin with a mass ratio of 2% to hydrolyze the product for 4 hours, spray the hydrolyzed product at an air inlet temperature of 230°C, and a pump speed of 65r / min to obtain phoenix clothes hydrolyzed powder, then add 0.0025g of melatonin, mix evenly, and After sterilization under 30W ultraviolet lamp for 40min, the capsules were filled under aseptic conditions.

Embodiment 2

[0023] Embodiment 2: capsule preparation

[0024] Take 500g of phoenix clothes and add 25 times the mass of water, extract at 100°C for 4h, then centrifuge at 3700r / min for 25min, take the supernatant, add 9 times the mass of water to the filter residue, and extract at 100°C for 1.5h, Afterwards, centrifuge at 3700r / min for 25min, take the supernatant, and combine the two filtrates to obtain a mixed extract; place the mixed extract in a rotary evaporator at 75°C, evaporate and concentrate to 1 / 15 of the volume of the original mixed extract; The concentrate was hydrolyzed by trypsin with a mass ratio of 2.5% for 4 hours, and the hydrolyzed product was spray-dried at an air inlet temperature of 270°C and a pump speed of 70r / min to obtain Phoenix clothes hydrolyzed powder, then added 0.0025g of melatonin, and mixed well , After sterilizing under 33W ultraviolet lamp for 38min, the capsules were filled under aseptic conditions.

Embodiment 3

[0025] Embodiment 3: capsule preparation

[0026] Take 600g of phoenix clothes and add 30 times the mass of water, extract at 100°C for 3h, then centrifuge at 4000r / min for 30min, take the supernatant, add 10 times the mass of water to the filter residue, extract at 100°C for 1h, and then Centrifuge at 4000r / min for 30min, take the supernatant, combine the two filtrates to obtain a mixed extract; place the mixed extract in a rotary evaporator at 80°C, evaporate and concentrate to 1 / 20 of the volume of the original mixed extract; Add mass ratio of 3% trypsin to hydrolyze the product for 3 hours, spray the hydrolyzed product at an air inlet temperature of 280° C., and a pump speed of 80 r / min to obtain phoenix clothes hydrolyzed powder, then add 0.002 g of melatonin, mix well, After sterilizing under 35W ultraviolet light for 35min, the capsules were filled under aseptic conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com