A three-dimensional electrode structure of a diamond ultraviolet detector and its manufacturing method

A technology of ultraviolet detector and three-dimensional electrode, which is applied in the field of photoelectric detection, can solve the problems of long carrier collection time, difficult separation of substrate and thin film, and low collection efficiency, so as to improve responsivity and time response performance, surface area / The effect of increasing the volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

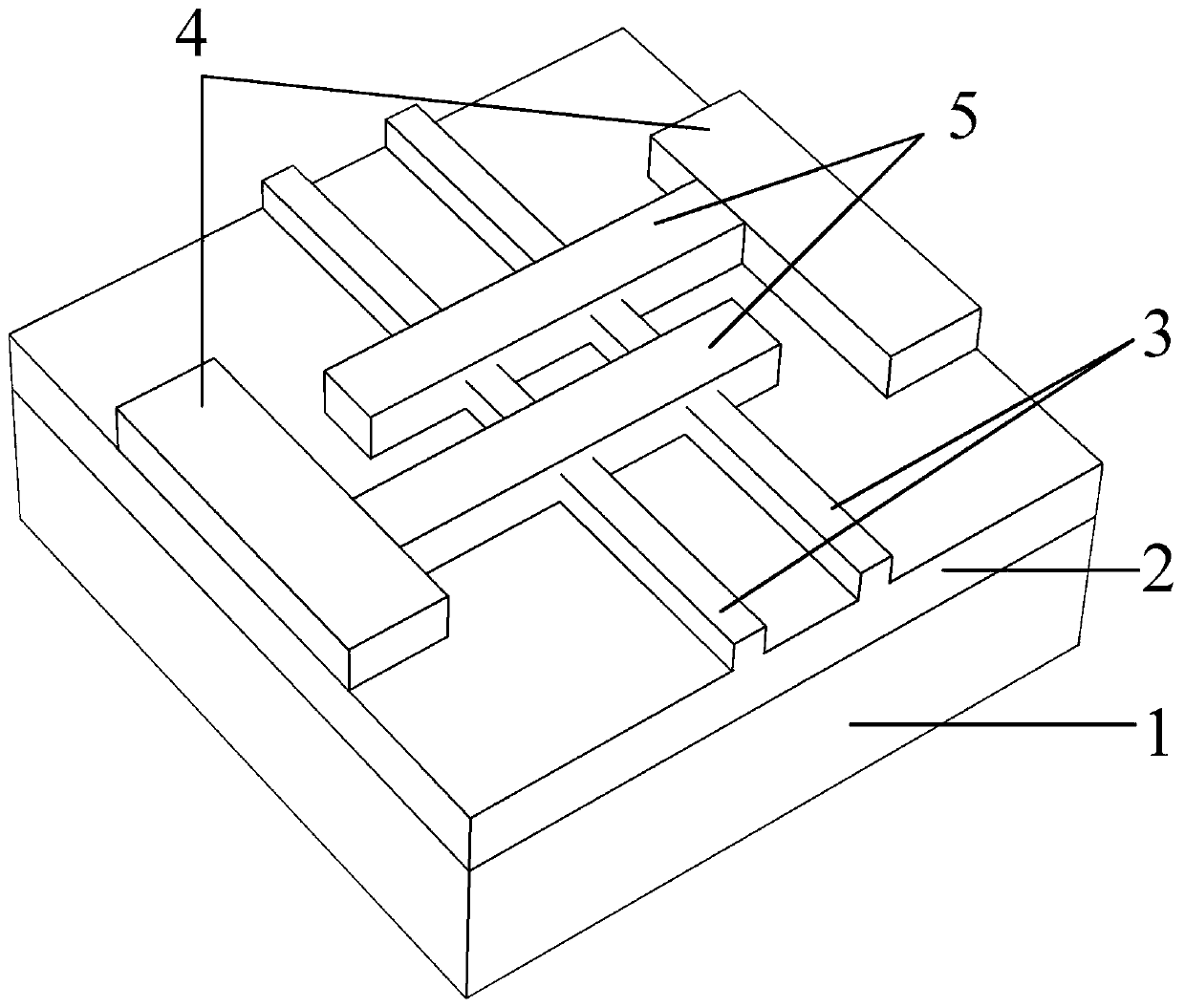

[0040] Such as figure 1 , three-dimensional electrode structure of diamond ultraviolet detector, single crystal diamond substrate 1 is intrinsic single crystal diamond synthesized under high temperature and high pressure, with a size of 3*3*0.3mm 3 . Using the MPCVD method to epitaxially grow a 250nm intrinsic single crystal diamond epitaxial layer 2 on the surface of a single crystal diamond substrate 1, the growth conditions are: the reaction gas is methane, hydrogen and nitrogen, the growth pressure is 80 Torr, the gas flow rate is 500 sccm, and the volume occupied by methane The percentage is 0.1%, the volume percentage of nitrogen gas is 0.001%, and the substrate temperature is 900°C. The concentration of nitrogen element in the final intrinsic single crystal diamond epitaxial layer 2 is 0.01ppm. After the growth is completed, a metal Ti strip array is prepared on the intrinsic single crystal diamond epitaxial layer 2 as a mask layer by using standard photolithography p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com