A kind of preparation method of graphene/polyamide 6 composite fiber

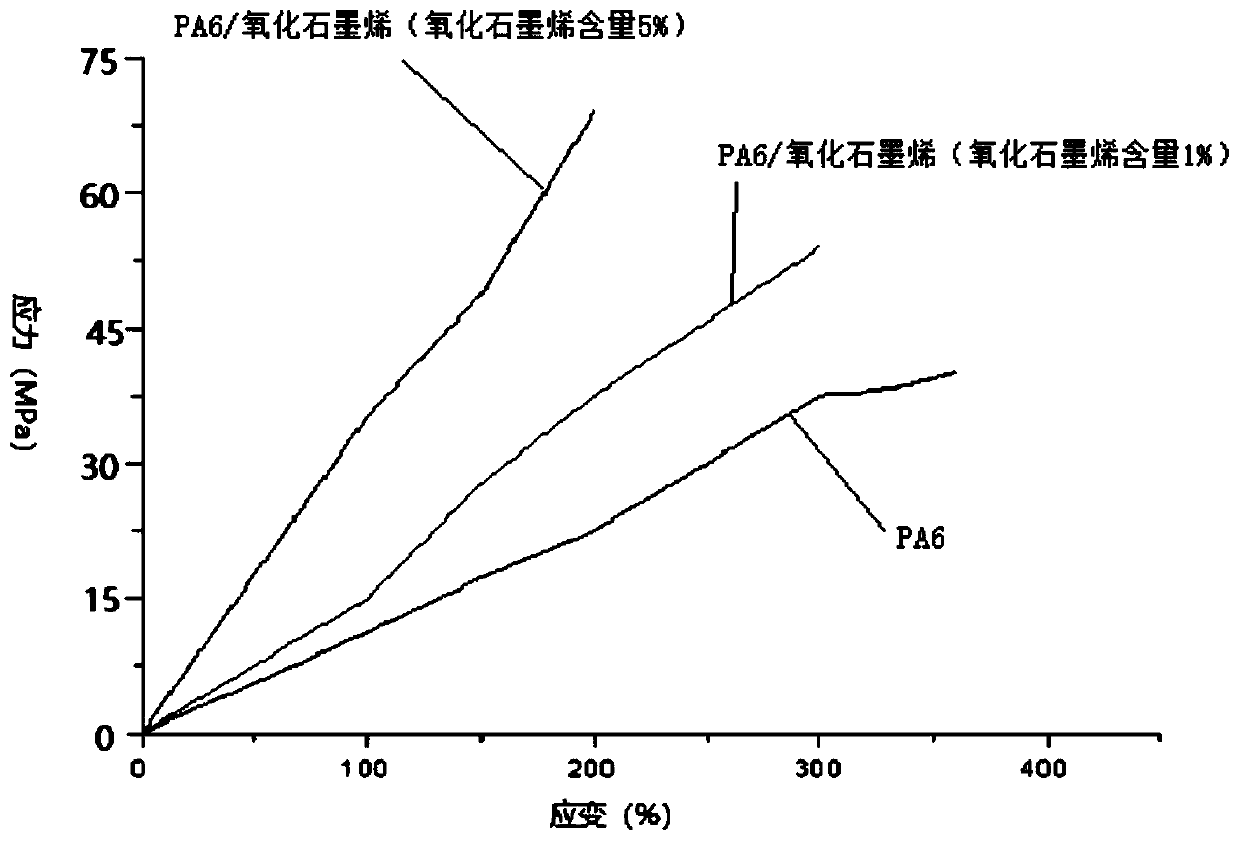

A composite fiber and polyamide technology, which is applied in the field of fiber production, can solve the problems of long electrospinning production process, unstable product consistency, and affecting the quality of spun silk, so as to achieve safe and controllable preparation process, light weight, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

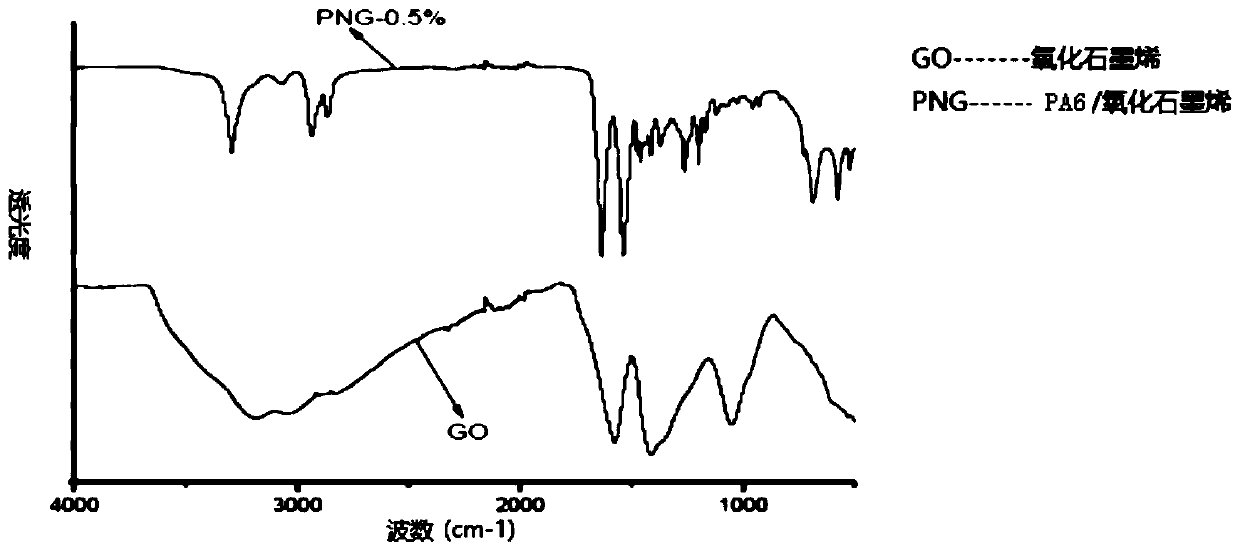

[0028] A preparation method of graphene / polyamide 6 composite fiber, comprising the following steps:

[0029] (1) Take caprolactam, 6-aminocaproic acid, manganese chloride, graphene oxide and hypophosphorous acid solution, hypophosphorous acid solution is the hypophosphorous acid aqueous solution of concentration 50%, water caprolactam, 6-aminocaproic acid, manganese chloride, The mass ratio of graphene oxide and hypophosphorous acid is 9:1:0.001:0.1:0.0025, add it to the reaction vessel, open the condensed water, start to feed nitrogen gas, and then under the nitrogen protection atmosphere, stir while heating, and raise the temperature to 200 ℃ heat preservation reaction for 3 hours, then further increase the temperature to 250 ℃ heat preservation reaction for 5 hours, after the reaction, pour the reaction product out of the reaction container to obtain a graphene / polyamide 6 polymer, close the nitrogen and condensed water;

Embodiment 2

[0034] A preparation method of graphene / polyamide 6 composite fiber, comprising the following steps:

[0035] (1) Take caprolactam, 6-aminocaproic acid, manganese chloride, graphene oxide and hypophosphorous acid solution, hypophosphorous acid solution is the hypophosphorous acid aqueous solution of concentration 50%, water caprolactam, 6-aminocaproic acid, manganese chloride, The mass ratio of graphene oxide and hypophosphorous acid is 9:1:0.005:0.5:0.0075. Add it to the reaction vessel, open the condensed water, start to feed nitrogen gas, and then stir while heating under nitrogen protection atmosphere, and raise the temperature to 220 ℃ heat preservation reaction for 2 hours, then further increase the temperature to 270 ℃ heat preservation reaction for 4 hours, after the reaction, pour the reaction product out of the reaction container to obtain graphene / polyamide 6 polymer, close the nitrogen and condensed water;

[0036] (2) Graphene / polyamide 6 polymer is mixed with for...

Embodiment 3

[0040] A preparation method of graphene / polyamide 6 composite fiber, comprising the following steps:

[0041] (1) Take caprolactam, 6-aminocaproic acid, manganese chloride, graphene oxide and hypophosphorous acid solution, hypophosphorous acid solution is the hypophosphorous acid aqueous solution of concentration 50%, water caprolactam, 6-aminocaproic acid, manganese chloride, The mass ratio of graphene oxide and hypophosphorous acid is 9:1:0.003:0.3:0.004, add it to the reaction vessel, open the condensed water, start to feed nitrogen gas, then under the nitrogen protection atmosphere, stir while heating, and raise the temperature to 210 ℃ heat preservation reaction for 2.5 hours, then further increase the temperature to 260 ℃ heat preservation reaction for 4.5 hours, after the reaction, pour the reaction product out of the reaction container to obtain graphene / polyamide 6 polymer, turn off nitrogen and condensed water;

[0042] (2) Graphene / polyamide 6 polymer was mixed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com