Self-healing sensing high molecular composite material based on ordered conductive network structure, and preparation method thereof

A composite material and network structure technology, applied in the field of sensing materials, can solve the problems of insufficient sensitivity, inability to apply sensing, and low resistance change, and achieve the effects of good conductivity, simple preparation method, and large resistance change rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

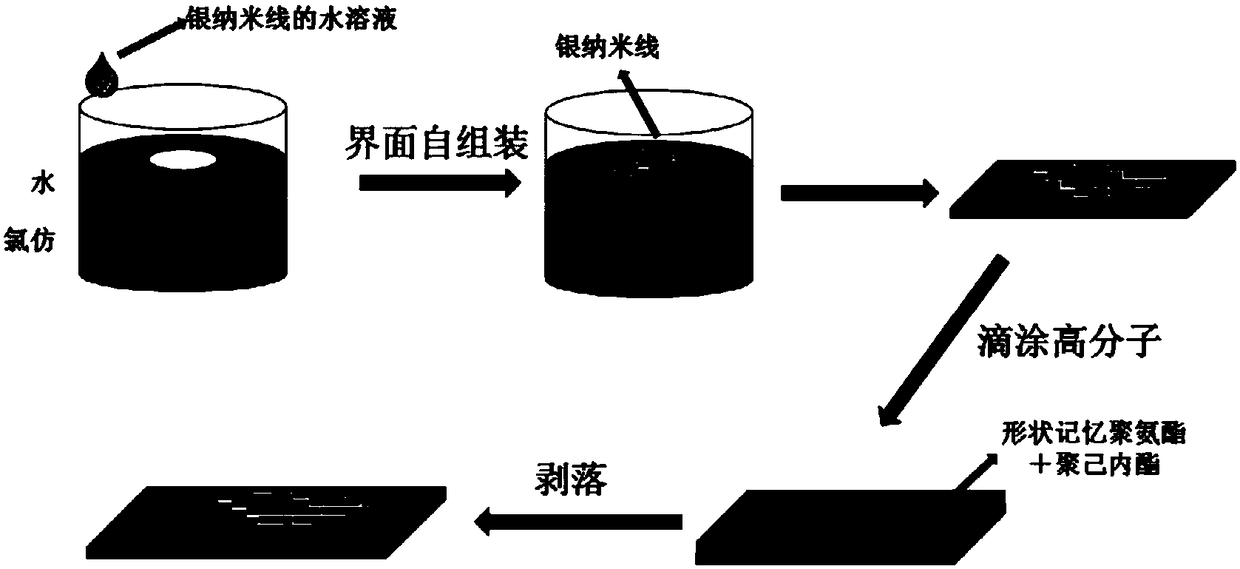

[0030] (1) Add the aqueous solution of 10mg / ml silver nanowires into the chloroform solution drop by drop at the glass wall. After the orientation of the silver nanowires is completed, take out the ordered silver nanowires with a 10×25mm glass sheet to obtain Ordered silver nanowire conductive film with a mass of 1.56 mg, the specific process is as follows figure 1 shown.

[0031] (2) Mix polycaprolactone and polyurethane respectively dissolved in N,N dimethylacetamide, the total mass of the polymer mixture is 30mg, of which polycaprolactone accounts for 30%, stir for 0.5h, and then drop-coat Or spin-coat on the above-mentioned ordered silver nanowire conductive film, put it in a 70°C oven and heat it for 12 hours, and then put it in a vacuum drying oven for 12 hours in vacuum to obtain a self-healing sensor based on an ordered conductive network structure. polymer composites. The morphology of the material was observed with a scanning electron microscope, such as figure 2...

Embodiment 2

[0034] (1) Add the aqueous solution of 10mg / ml silver nanowires into the chloroform solution drop by drop at the glass wall. After the orientation of the silver nanowires is completed, take out the ordered silver nanowires with a 10×25mm glass sheet to obtain A conductive film of ordered silver nanowires with a mass of 0.64 mg.

[0035] (2) Mix polycaprolactone and polyurethane respectively dissolved in N,N dimethylacetamide, the total mass of the polymer mixture is 30mg, of which polycaprolactone accounts for 30%, stir for 0.5h, and then drop-coat or Spin-coated on the above-mentioned ordered silver nanowire conductive film, put it into a 70°C oven for heating for 12 hours, and then put it in a vacuum drying oven for 12 hours to vacuum dry to obtain a self-healing sensor sensor based on an ordered conductive network structure. molecular composites.

[0036] (3) Cut the self-healing sensing polymer composite material into a sample whose length*width*thickness is 25mm*5mm*0.05...

Embodiment 3

[0038] (1) Add the aqueous solution of 10mg / ml silver nanowires into the chloroform solution drop by drop at the glass wall. After the orientation of the silver nanowires is completed, take out the ordered silver nanowires with a 10×25mm glass sheet to obtain A conductive film of ordered silver nanowires with a mass of 2.37mg.

[0039] (2) Mix polycaprolactone and polyurethane respectively dissolved in N,N dimethylacetamide, the total mass of the polymer mixture is 30mg, of which polycaprolactone accounts for 30%, stir for 0.5h, and then drop-coat or Spin-coated on the above-mentioned ordered silver nanowire conductive film, put it into a 70°C oven for heating for 12 hours, and then put it in a vacuum drying oven for 12 hours to vacuum dry to obtain a self-healing sensor sensor based on an ordered conductive network structure. molecular composites.

[0040] (3) Cut the self-healing sensing polymer composite material into a sample whose length*width*thickness is 25mm*5mm*0.05m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com