Preparation method of hierarchical porous alumina foam ceramic comparable to aerogel

A technology of porous alumina and foam ceramics, which is applied in the field of ceramic materials, can solve the problems of high equipment cost and complicated process, and achieve the effect of fine grain size, simple process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare a thin aluminum sol slurry with a solid phase content of 3wt%, add 0.8wt% sodium lauryl sulfate, and then adjust the pH to 8.1 with water.

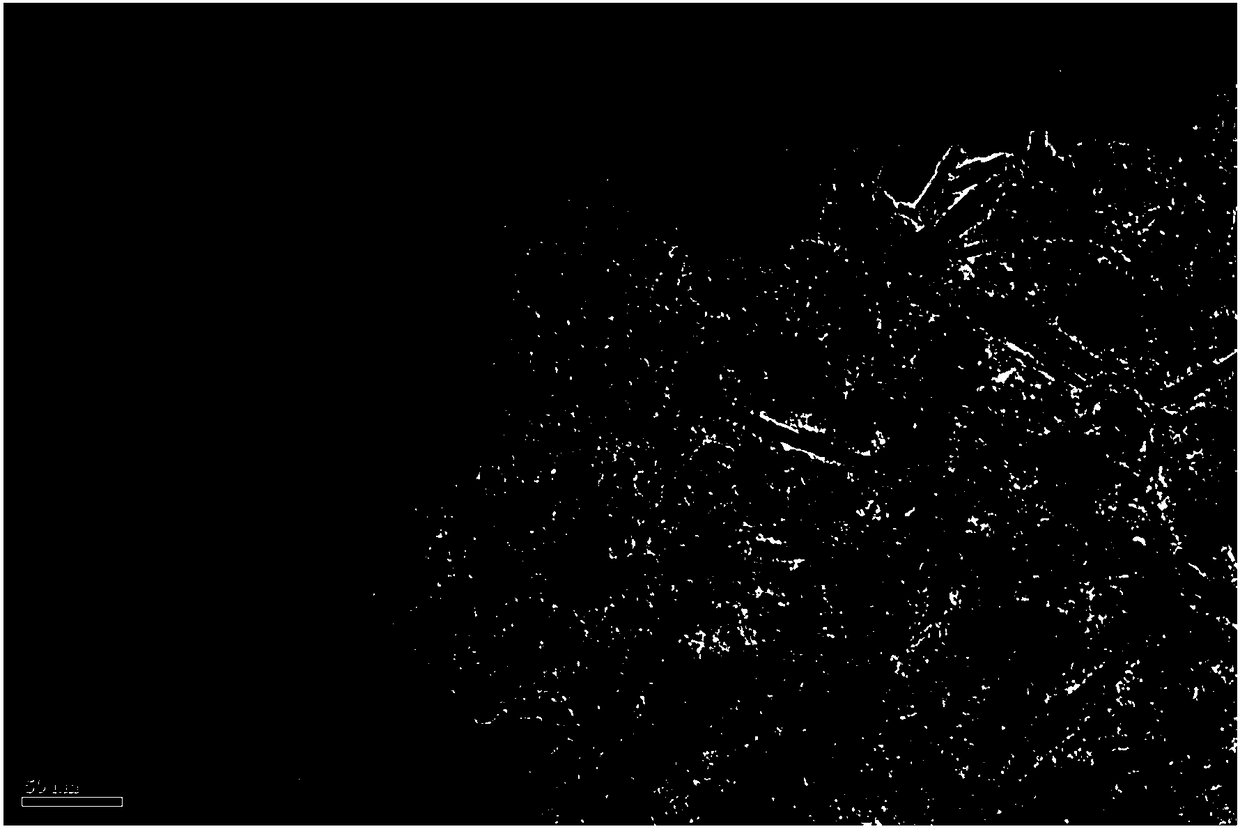

[0025] (2) Utilize a mechanical mixer to stir and foam at a speed of 2000rmp for 5min to obtain a stable ceramic foam slurry, such as figure 2 Ultra stable foam shown. Dry 48h under 80% humidity environment, obtain aluminum sol foam ceramics such as image 3 and Figure 4 shown.

[0026] (3) The porosity of the prepared aluminum sol foam ceramics is 99.01%, and the specific surface area is 278.6m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com