Low hydration heat copper slag based composite cementitious material and preparation method thereof

A technology of composite cementitious materials and low heat of hydration, applied in cement production, etc., can solve problems such as increased cement production costs, and achieve the effect of being suitable for large-scale mass production, improving utilization rate, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

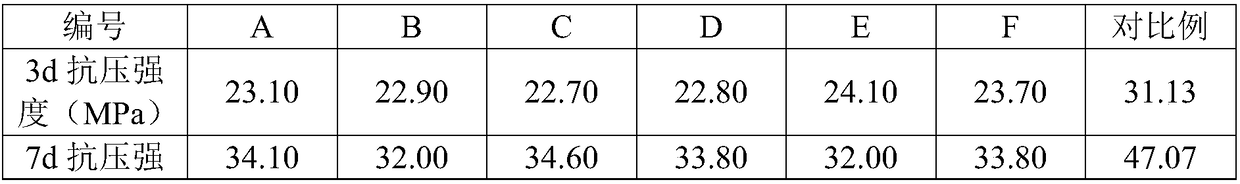

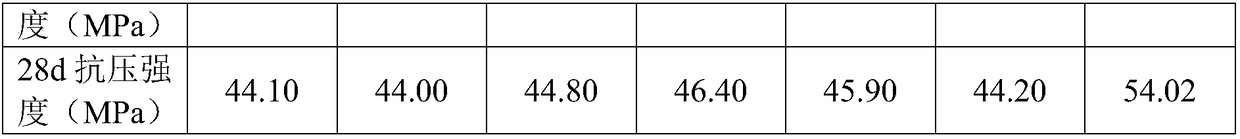

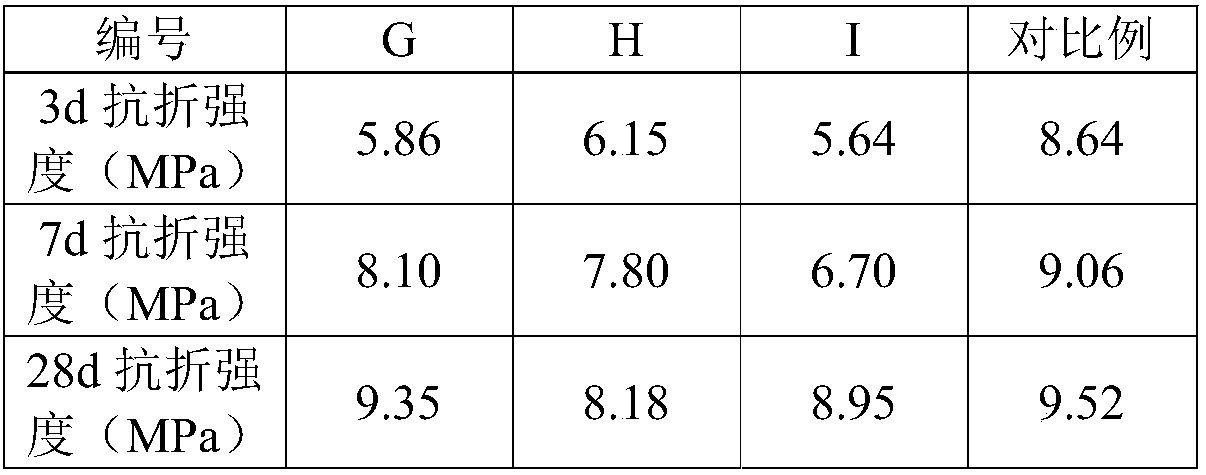

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned low heat of hydration copper slag-based composite cementitious material comprises:

[0036] Step 1: Put the copper slag in an oven for 3 to 4 hours, set the temperature of the oven to 110°C, and obtain the dried copper slag;

[0037] Step 2: Put the copper slag in a ball mill and grind it for 30-120 minutes to obtain a specific surface area of 500-750m 2 / kg copper slag powder;

[0038] Step 3: Add 20-30 parts of copper slag powder into 70-80 parts of Portland cement and stir evenly in parts by weight to obtain the copper slag-based composite cementitious material with low heat of hydration.

[0039] The working principle of the present invention is: copper slag and cement clinker have similar chemical composition, and the active SiO contained 2 In the later stage of hydration and the hydration product Ca(OH) 2 The following weak pozzolanic reaction occurs: (C-S-H gelling), which has potential gelling properties and can...

Embodiment 1

[0058] A copper slag-based composite cementitious material with low heat of hydration and a preparation method thereof, comprising the following components in parts by weight: 20 parts of copper slag powder, 80 parts of cement and 40 parts of water.

[0059] The copper slag powder is prepared from high-temperature water-quenched waste slag discharged from a copper smelter by ball milling for 30 minutes, wherein the copper slag powder includes Fe 2 o 3 , SiO 2 、Al 2 o 3 , CaO, etc., A1 in the copper slag powder 2 o 3 and SiO 2 The sum of the mass contents is greater than 80%, and the apparent density of the copper slag powder is 3.4g / m 3 Specifically, put the copper slag in the oven for 3 hours, set the temperature of the oven at 110°C to obtain the dried copper slag, and then put the copper slag in a ball mill for grinding for 30 minutes to obtain a specific surface area of 503m 2 / kg of copper slag powder, the cement is Portland cement with a label of 42.5 or more. ...

Embodiment 2

[0067] A copper slag-based composite cementitious material with low heat of hydration and a preparation method thereof, comprising the following components in parts by weight: 20 parts of copper slag powder, 80 parts of cement and 40 parts of water.

[0068] The copper slag powder is prepared from high-temperature water-quenched waste slag discharged from a copper smelter by ball milling for 60 minutes, wherein the copper slag powder includes Fe 2 o 3 , SiO 2 、Al 2 o 3 , CaO, etc., A1 in the copper slag powder 2 o 3 and SiO 2 The sum of the mass contents is greater than 80%, and the apparent density of the copper slag powder is 3.5g / m 3 Specifically, put the copper slag in the oven for 3.5 hours, set the oven temperature to 110°C to obtain the dried copper slag, and then put the copper slag in a ball mill for grinding for 60 minutes to obtain a specific surface area of 627m 2 / kg of copper slag powder, the cement is Portland cement with a label of 42.5 or more.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com