Composite biological filler for promoting rapid start-up and stable operation of anaerobic ammonium oxidation and preparation method and application thereof

An anaerobic ammonium oxidation and quick-start technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of destroying the packing structure, affecting water quality, small specific surface area, etc., and achieve good growth Effects of environment, promotion of electron transfer, and improvement of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

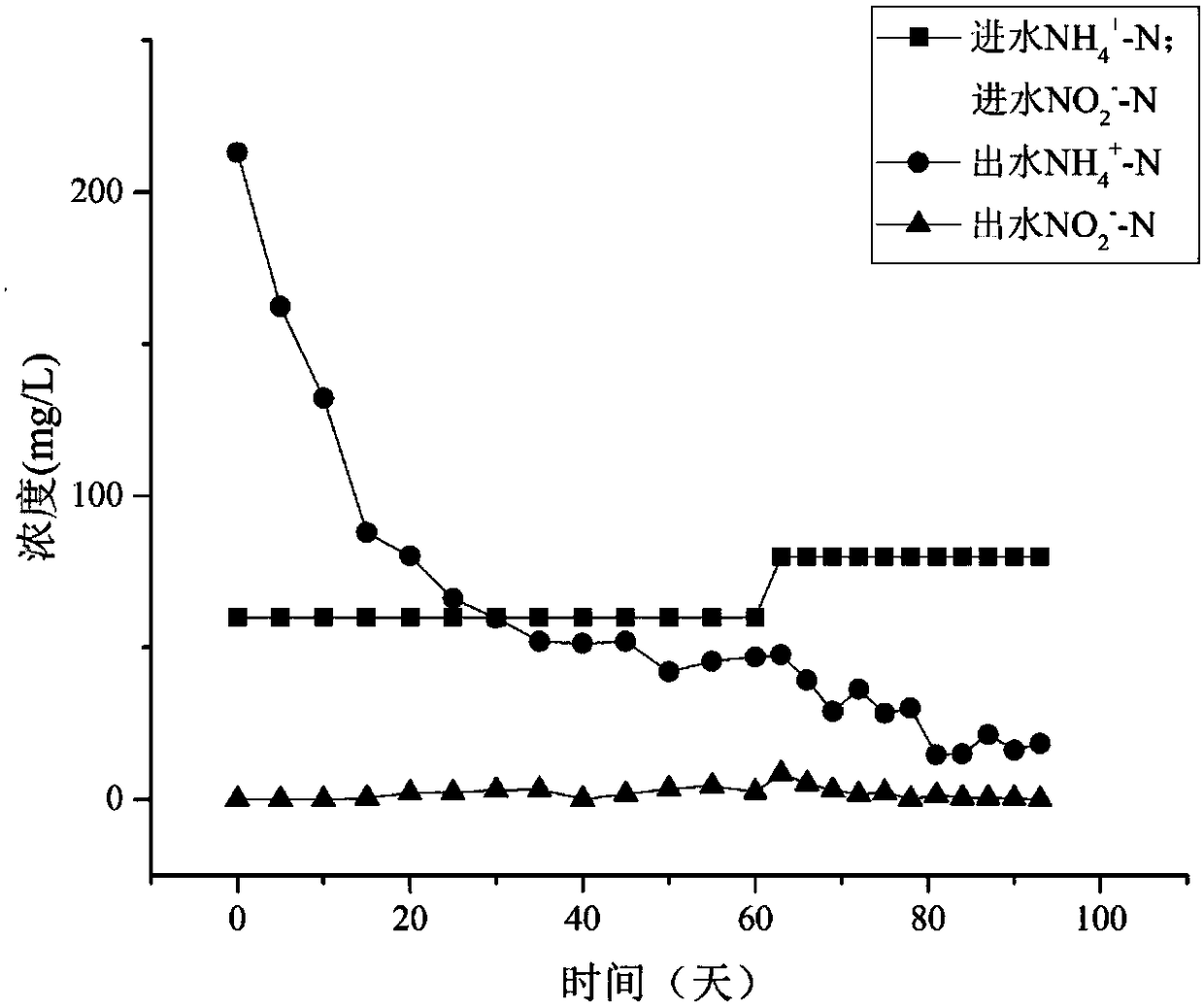

Embodiment 1

[0050] Weigh the granular activated carbon, and use a small grinder to grind the laboratory granular activated carbon into a powder of 5 μm. Add the obtained powdered activated carbon into NaCl solution with a mass concentration of 5% to soak for 1 hour, rinse and dry it for later use. Weigh 60g of polyvinyl alcohol, 40g of glucomannan gum, 10g of calcium chloride and 10g of 0.1mm iron powder into 500mL of distilled water, then put 20g of the prepared activated carbon powder into the solution, stir and dissolve to form a cross-linking mixed solution, and stir evenly.

[0051] Add 50g polyester polyol, 50g polyisocyanate, 100g water, 20g tetramethylethylenediamine catalyst, 35g surfactant and 15g foaming agent into the container, stir at high speed for 2s, then add the prepared crosslinking mixed solution, After continuing to stir for 2 minutes, pour it into a mold for molding, and then put it in a refrigerator at 0° C. for 48 hours to obtain 200 g of composite polyurethane fil...

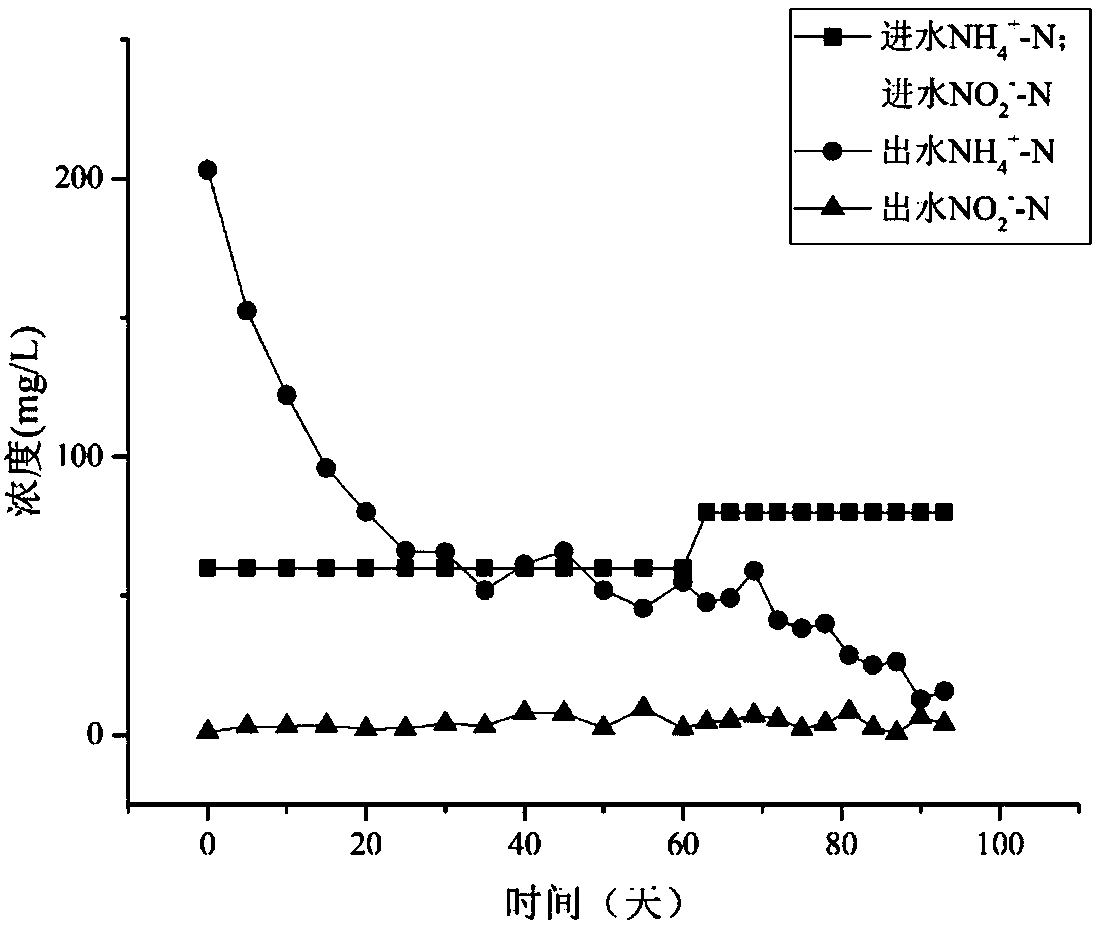

Embodiment 2

[0053] Weigh the granular activated carbon, and use a small grinder to grind the laboratory granular activated carbon into a powder of 20 μm. Add the obtained powdered activated carbon into NaCl solution with a mass concentration of 5% to soak for 1 hour, rinse and dry it for later use. Weigh 60g of polyvinyl alcohol, 20g of glucomannan gum, 10g of calcium chloride and 10g of 0.25mm iron powder into 500mL of distilled water, then put 10g of the prepared activated carbon powder into the solution, stir and dissolve to form a cross-linking mixed solution, and stir evenly.

[0054] Add 50g polyester polyol, 50g polyisocyanate, 100g water, 20g tetramethylethylenediamine catalyst, 35g surfactant and 15g foaming agent into the container, stir at high speed for 3s, then add the prepared crosslinking mixed solution, After continuing to stir for 2 minutes, it was poured into a mold for molding, and then stored in a refrigerator at 0° C. for 48 hours to obtain 179 g of composite polyuret...

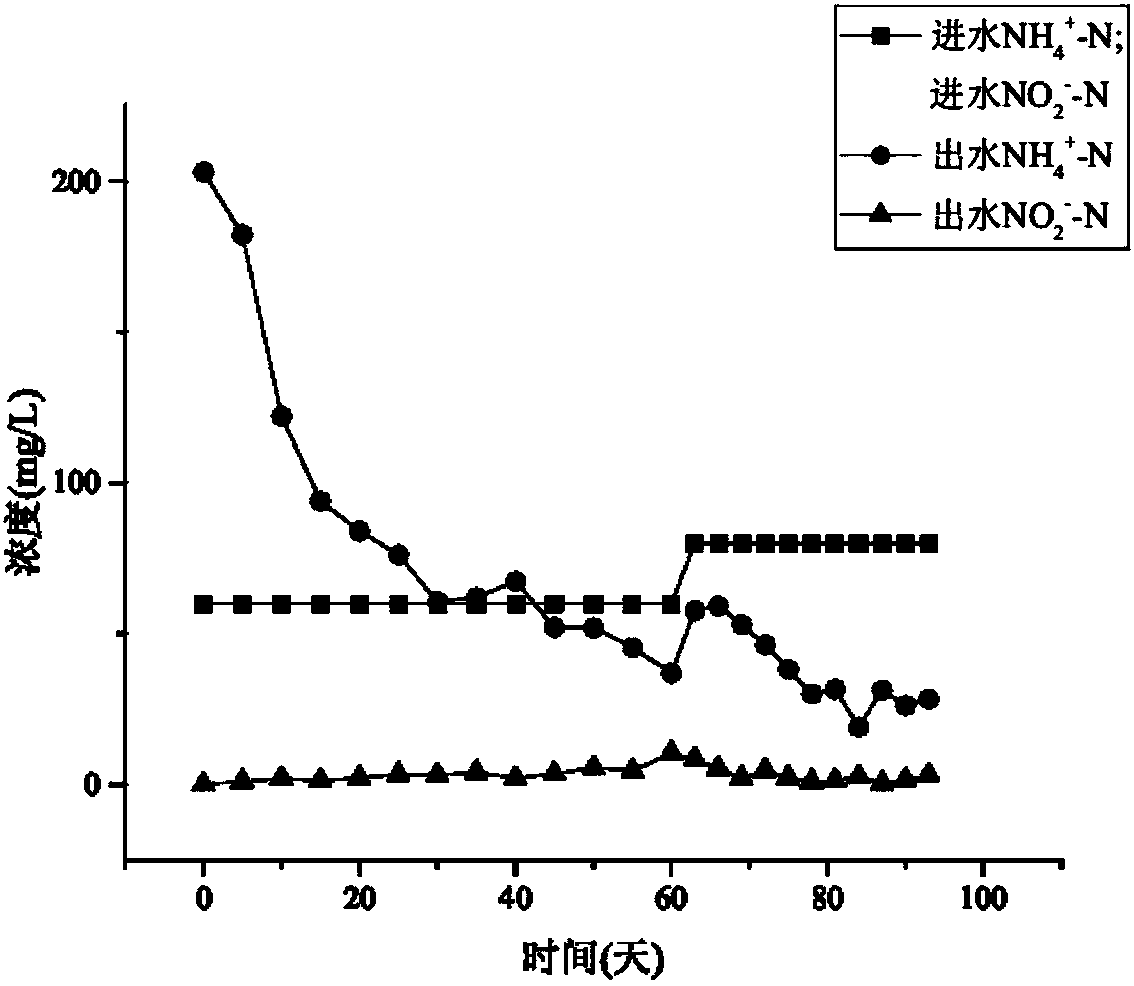

Embodiment 3

[0056] Weigh the granular activated carbon, and use a small grinder to grind the laboratory granular activated carbon into a powder of 50 μm. Add the obtained powdered activated carbon into NaCl solution with a mass concentration of 5% to soak for 1 hour, rinse and dry it for later use. Weigh 60g of polyvinyl alcohol, 30g of glucomannan gum, 10g of calcium chloride and 10g of 0.2mm iron powder into 500mL of distilled water, then put 15g of the prepared activated carbon powder into the solution, stir and dissolve to form a cross-linking mixed solution, and stir evenly.

[0057] Add 50g of polyester polyol, 50g of polyisocyanate, 100g of water, 20g of tetramethylethylenediamine catalyst, 35g of surfactant and 15g of foaming agent into the container, stir at high speed for 2.5s, and then add the prepared crosslinking mixed solution , after continuing to stir for 2 minutes, pour it into a mold for molding, then put it in a refrigerator and store it at 0°C for 48 hours to obtain 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com