Single layer polymer memory based on MEH-PPV: PCBM donor-acceptor structure

A technology of MEH-PPV and polymer, which is applied in the field of single-layer polymer memory and its preparation, can solve the problems of difficulty in preparing large-area devices, unfavorable environmental impact, and high manufacturing cost, and achieve simple process, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

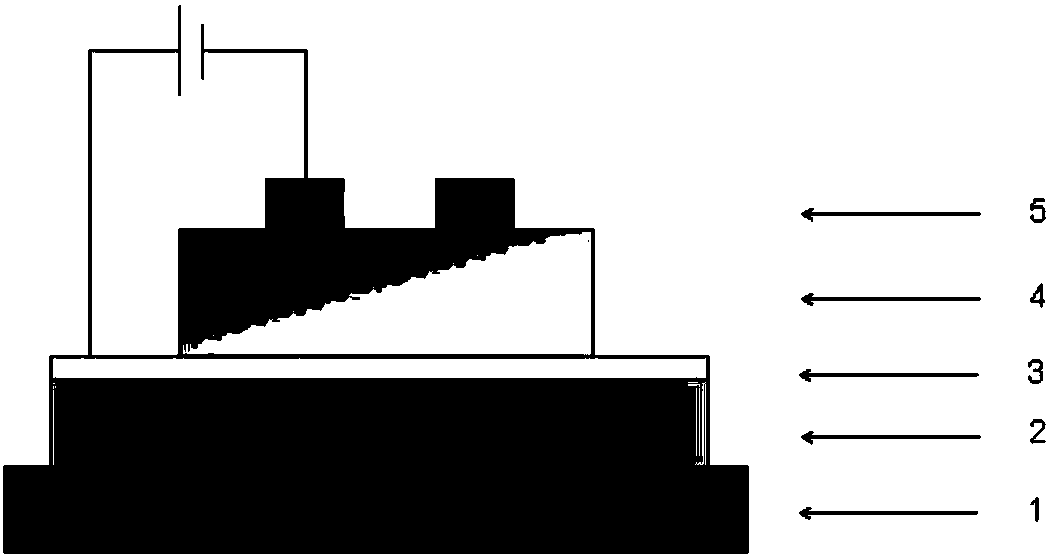

[0042] The blending ratio of MEH-PPV(M) and PCBM(P) is selected as M:P=1:1 (weight ratio), and the device structure used is ITO / PEDOT:PSS / M:P / Au.

[0043] First, the ITO on the ITO glass is photolithographically formed into electrodes with a width of 4 mm and a length of 30 mm, then cleaned and dried with nitrogen, and treated with ultraviolet ozone plasma for 4-10 minutes. Next, spin-coat PEDOT:PSS polymer aqueous solution on the cleaned ITO electrode, and place it in a vacuum drying oven with a constant temperature of 50-150° C. for 0.5-3 hours to vacuum dry. Spin-coat the mixed solution of MEH-PPV:PCBM on the PEDOT:PSS with good film formation, and bake in a vacuum drying oven with a constant temperature of 50-200°C for 10-60 minutes. Finally, the sample is transferred to the coating equipment, in a vacuum of (1 ~ 5) × 10 -4 Under the condition of Pa, the gold on the top electrode intersecting with the bottom electrode ITO is vapor-deposited. Among them, the thickness of ...

Embodiment 2

[0046] The blending ratio of MEH-PPV(M) and PCBM(P) is selected as M:P=2:1 (weight ratio), and the device structure used is ITO / PEDOT:PSS / M:P / Au.

[0047] First, the ITO on the ITO glass is photolithographically formed into electrodes with a width of 4 mm and a length of 30 mm, then cleaned and dried with nitrogen, and treated with ultraviolet ozone plasma for 4-10 minutes. Next, spin-coat PEDOT:PSS polymer aqueous solution on the cleaned ITO electrode, and place it in a vacuum drying oven with a constant temperature of 50-150° C. for 0.5-3 hours to vacuum dry. Spin-coat the mixed solution of MEH-PPV:PCBM on the PEDOT:PSS with good film formation, and bake in a vacuum drying oven with a constant temperature of 50-200°C for 10-60 minutes. Finally, the sample is transferred to the coating equipment, in a vacuum of (1 ~ 5) × 10 -4 Under the condition of Pa, the gold on the top electrode intersecting with the bottom electrode ITO is vapor-deposited. Among them, the thickness of ...

Embodiment 3

[0050] The blending ratio of MEH-PPV(M) and PCBM(P) is selected as M:P=3:1 (weight ratio), and the device structure used is ITO / PEDOT:PSS / M:P / Au.

[0051] First, the ITO on the ITO glass is photolithographically formed into electrodes with a width of 4 mm and a length of 30 mm, then cleaned and dried with nitrogen, and treated with ultraviolet ozone plasma for 4-10 minutes. Next, spin-coat PEDOT:PSS polymer aqueous solution on the cleaned ITO electrode, and place it in a vacuum drying oven with a constant temperature of 50-150° C. for 0.5-3 hours to vacuum dry. Spin-coat the mixed solution of MEH-PPV:PCBM on the PEDOT:PSS with good film formation, and bake in a vacuum drying oven with a constant temperature of 50-200°C for 10-60 minutes. Finally, the sample is transferred to the coating equipment, in a vacuum of (1 ~ 5) × 10 -4 Under the condition of Pa, the gold on the top electrode intersecting with the bottom electrode ITO is vapor-deposited. Among them, the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com