Preparation method of optical waveguide type minicircle resonant cavity humidity sensor coated with TiO2 thin film

A micro-ring resonant cavity and humidity sensor technology, applied in the field of optics and micro-nano systems, can solve the problems of being unable to adapt to extremely harsh environments, being susceptible to electromagnetic interference, and long response time, and achieving reduced size, high sensitivity, Effect of Fast Response Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

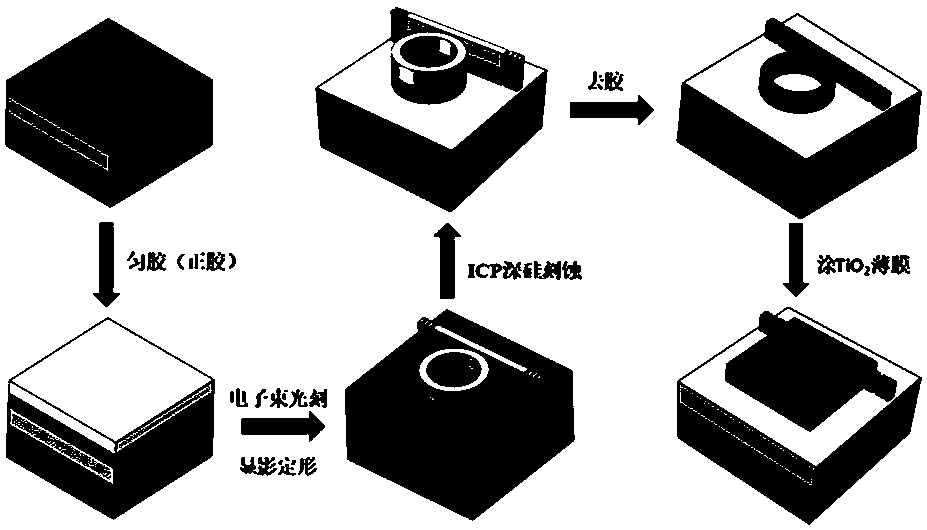

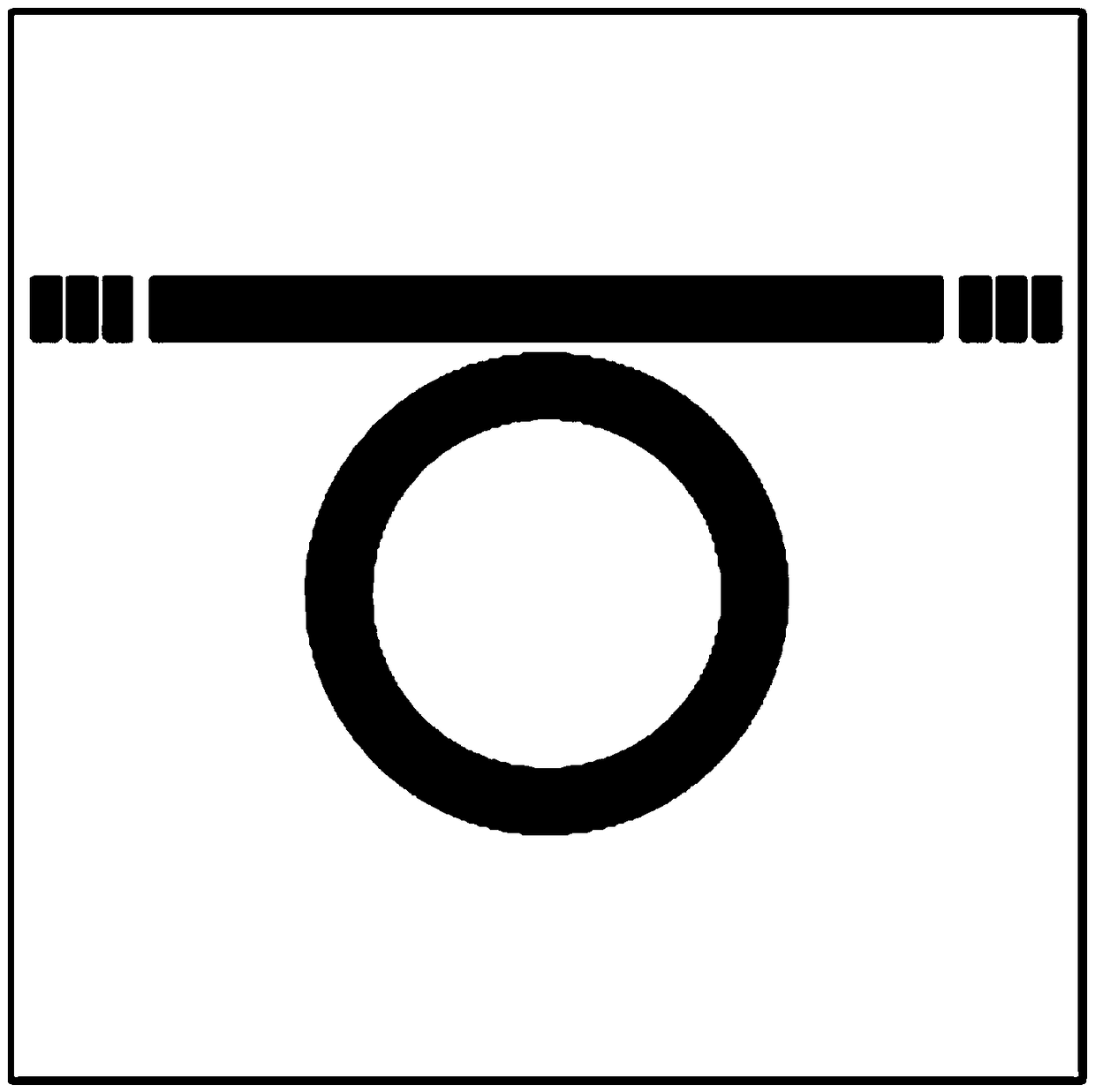

[0017] A coated TiO 2 Thin-film optical waveguide microring resonator humidity sensor, realize microring resonator on SOI substrate structure, photolithography of straight waveguide and grating, and TiO 2 The coating of the humidity-sensitive film utilizes the corridor mode effect of the ring resonant cavity to complete the measurement of the humidity. The manufacturing method includes the following steps:

[0018] The first step: SOI substrate cleaning, ultrasonic cleaning with anhydrous ethanol in turn to ensure that the SOI sample base surface is clean;

[0019] The second step: uniform glue, even a layer of positive photoresist on the top surface of the cleaned SOI substrate;

[0020] Step 3: Use an electron beam exposure system to expose the positive photoresist on the top surface of the SOI substrate, develop and fix it, and leave straight waveguide and microring resonant cavity-shaped structures on the positive photoresist layer. The adhesive layer, and the grating st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com