An oil-based wax remover

An oil-based clearing and waxing agent technology, applied in chemical instruments and methods, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems of low wax melting rate, high price, high density, etc., and achieve high wax melting rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

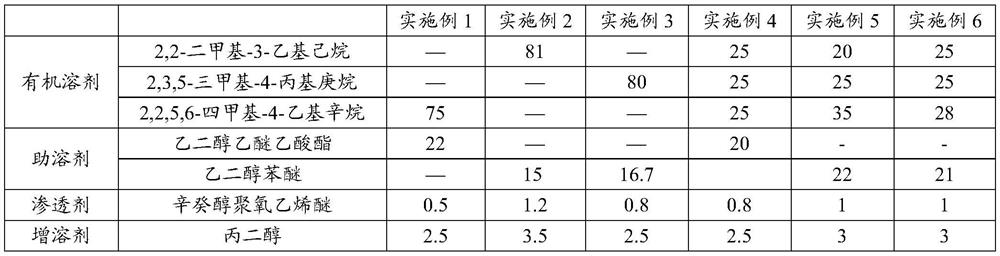

[0038] The composition of the oil-based wax remover of this embodiment is shown in Table 1.

[0039] The preparation method of the oil-based wax remover of this embodiment: 75g 2,2,5,6-tetramethyl-4-ethyloctane and 22g ethylene glycol ethyl ether acetate are added in the mixer to Stir at 1000r / min for 5min, then add 2.5g of propylene glycol, continue to stir for 5min, then add 0.5g of octadecyl alcohol polyoxyethylene ether, continue to stir for 5min, and obtain the oil-based wax remover of this embodiment.

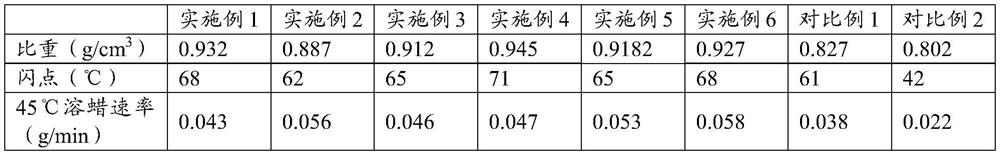

[0040] The properties of the oil-based wax remover of this embodiment are shown in Table 2.

Embodiment 2 to Embodiment 7

[0042] The compositions of Examples 2 to 7 are shown in Table 1. The preparation method is the same as that of Example 1, except that the specific substances and proportions used for the organic solvent, co-solvent, penetrating agent and solubilizer are adjusted according to Table 1.

[0043] The properties of the oil-based wax removers of Examples 2 to 7 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com