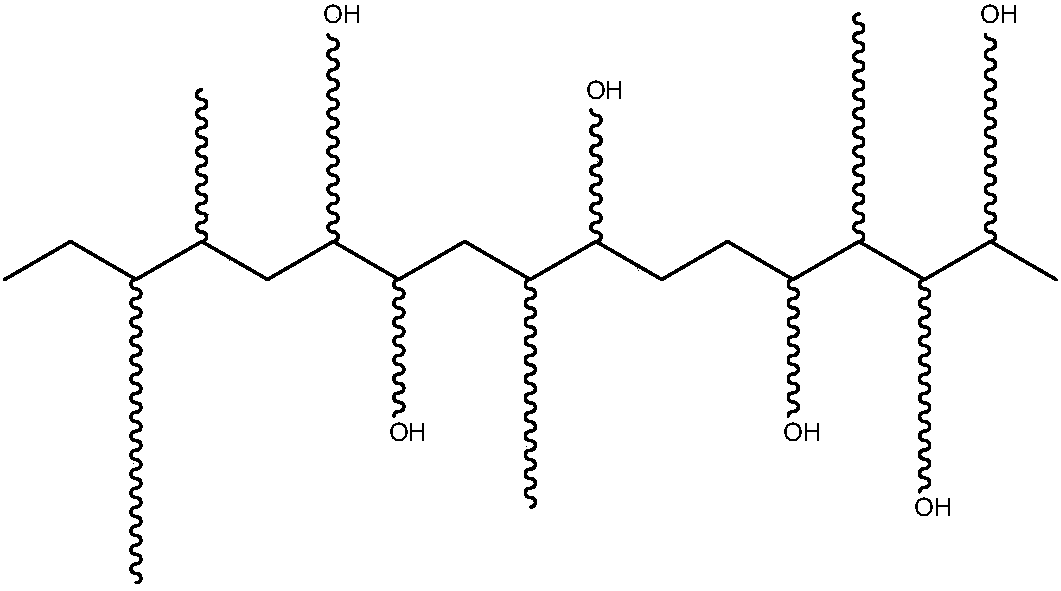

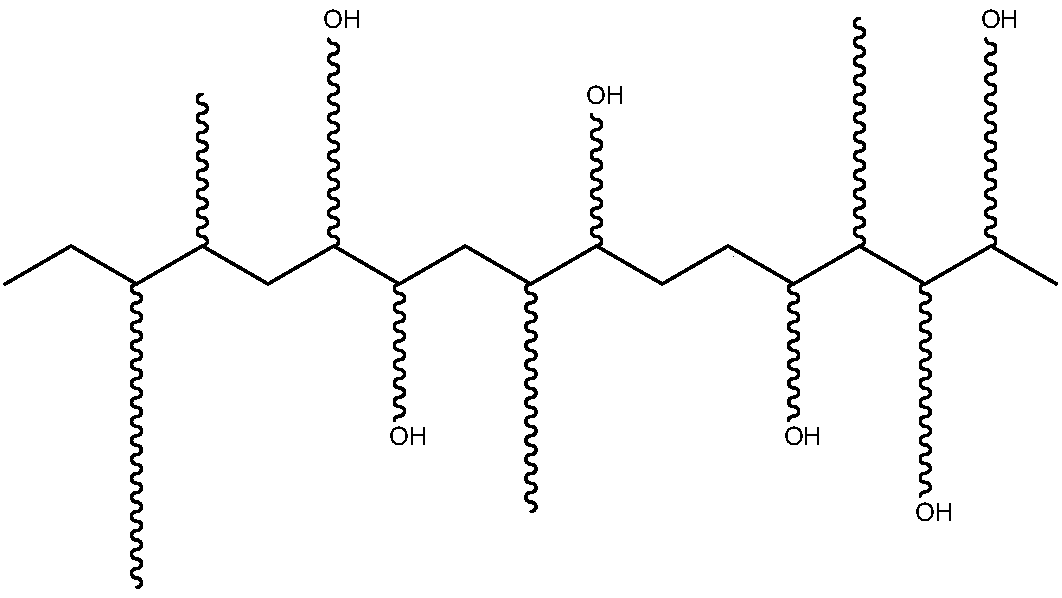

Comb-shaped multi-branched water-based polyurethane dispersion as well as preparation and application thereof

A water-based polyurethane, multi-branched technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as effect discounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Add 1g of trimethylolpropane and 1.5g of pentaerythritol (molar ratio 1:2) into 12g of isophorone diisocyanate (IPDI) dropwise, and stir at 80°C for 30 minutes; continue adding 9.2g of polytetrahydrofuran ether polyol ( Molecular weight 1000) was added dropwise to the above-mentioned reactants, stirred and reacted at 90°C for 30min; , double-terminated hydroxyl polymer content accounted for 30%) were added to the above reactants at intervals of 3:1 titration rate, while adding the initiator dibutyltin dilaurate accounting for 1‰ of the total reactants, stirring at 95 ° C Reaction 60min.

[0036] 50g polycarbonate dibasic alcohol (number-average molecular weight 1000) and 13.2g isophorone diisocyanate (IPDI) and above-mentioned reactant are joined in the drying reactor equipped with stirrer, temperature measuring instrument together, at 70 The reaction was stirred at °C for 2 hours. Subsequently, 2 g of dimethylolpropionic acid, 0.5 g of 1,4-butanediol and 0.1 g of dibu...

Embodiment 2

[0038] Add 3g of trimethylolpropane dropwise into 12g of isophorone diisocyanate (IPDI), stir and react at 80°C for 30 minutes; continue to add 9.2g of polytetrahydrofuran ether polyol (molecular weight 1000) dropwise into the above reactant, 90°C Stirring and reacting for 30 minutes; then 3g hydroxyl-terminated siloxane (molecular weight 600, double-terminated hydroxyl polymer content accounts for 30%) and 1g hydroxyl-terminated polyethylene glycol (molecular weight 500, double-terminal hydroxyl polymer content accounts for 50%) respectively Add the above-mentioned reactants at intervals of a titration rate of 1:3, and at the same time add the initiator dibutyltin dilaurate accounting for 1‰ of the total reactants, and stir and react at 95°C for 60 minutes.

[0039] 50g polyethylene oxide glycol (number-average molecular weight 2000) and 20g hexamethylene diisocyanate and 18g isophorone diisocyanate are added in the drying reactor equipped with stirrer, temperature measuring i...

Embodiment 1 and 2

[0049] The aqueous dispersion prepared in the embodiment of the present invention 1 and 2 and curing agent ( XP2655, purchased from Covestro Polymers (China) Co., Ltd.) in a disperser (FLUKO FA25 type, purchased from Fluke Fluid Machinery Manufacturing Co., Ltd.) at 16000rpm to mix and disperse evenly, add a wetting agent (model YMT 245 , purchased from Umitech (Beijing) Environmental Materials Technology Co., Ltd.) and adjusted the viscosity. After the viscosity was adjusted to 800mPa·s, the mixed solution was directly coated on the matting release paper and PVC leather ( Polyvinyl chloride artificial leather), fully dried in a blast oven at 90 and 120 °C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com