A red, green and blue light all-inorganic perovskite quantum dot and porous glass composite luminescent material and preparation method thereof

A technology of porous glass and luminescent materials, applied in luminescent materials, glass manufacturing equipment, inorganic chemistry, etc., can solve the problems of ion concentration quenching, poor stability, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

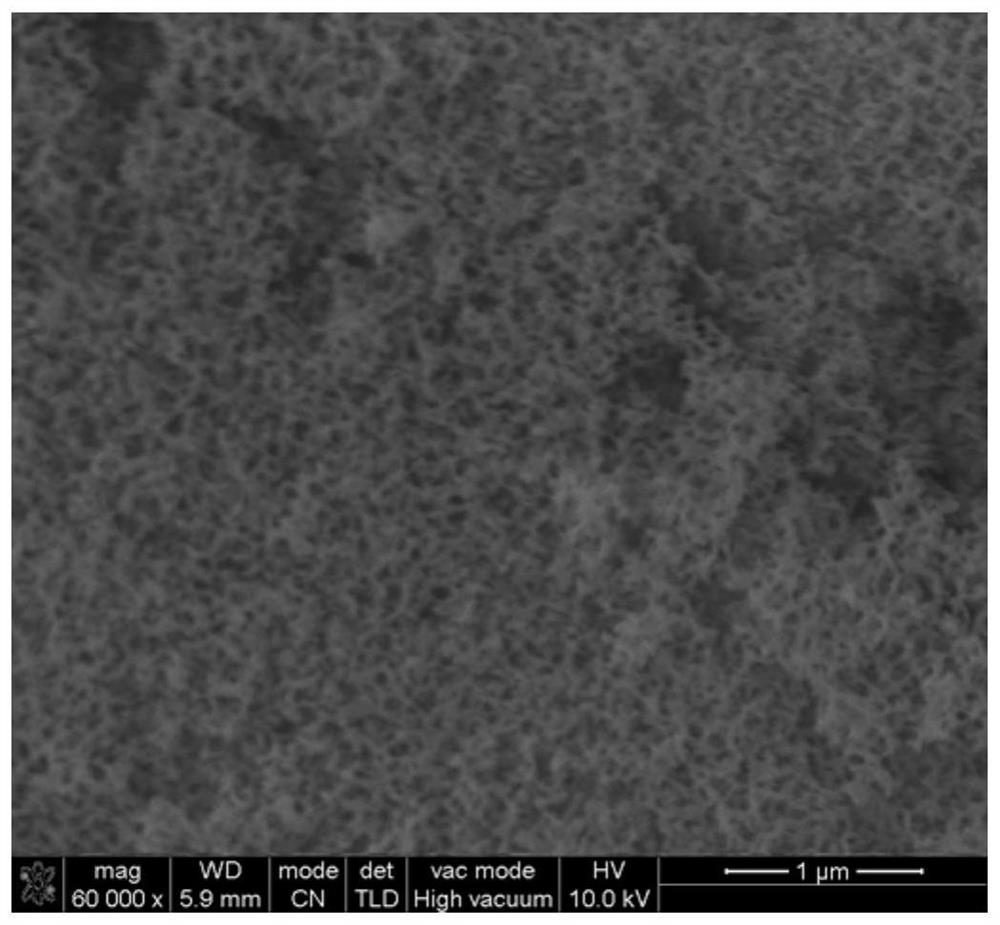

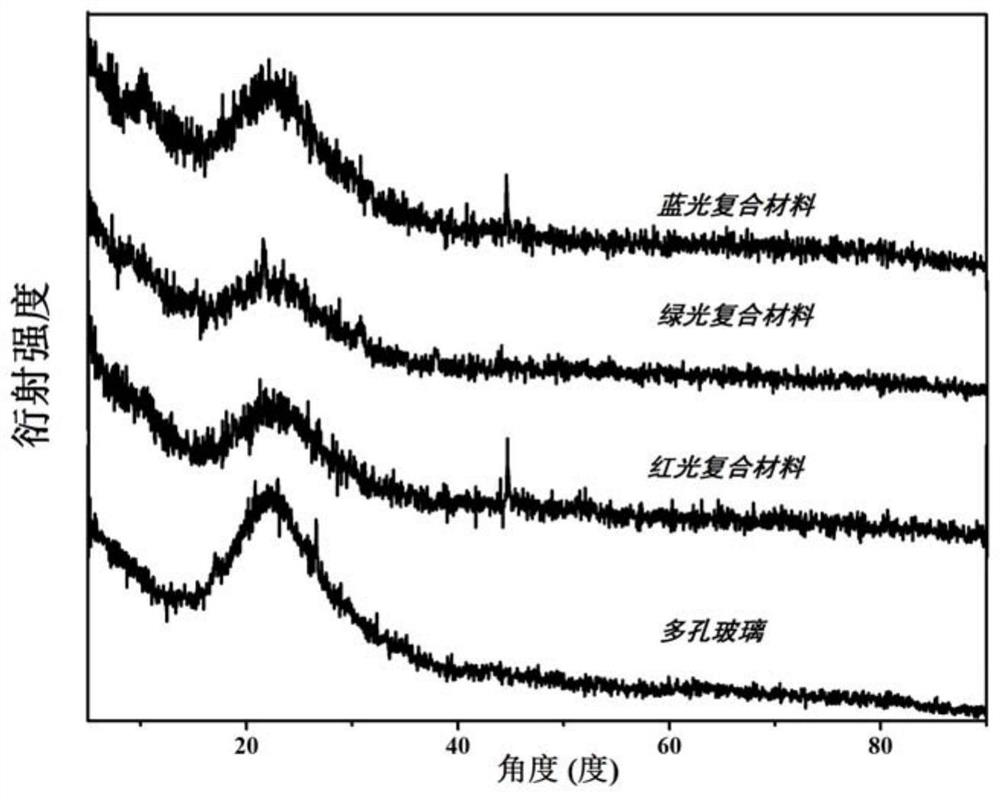

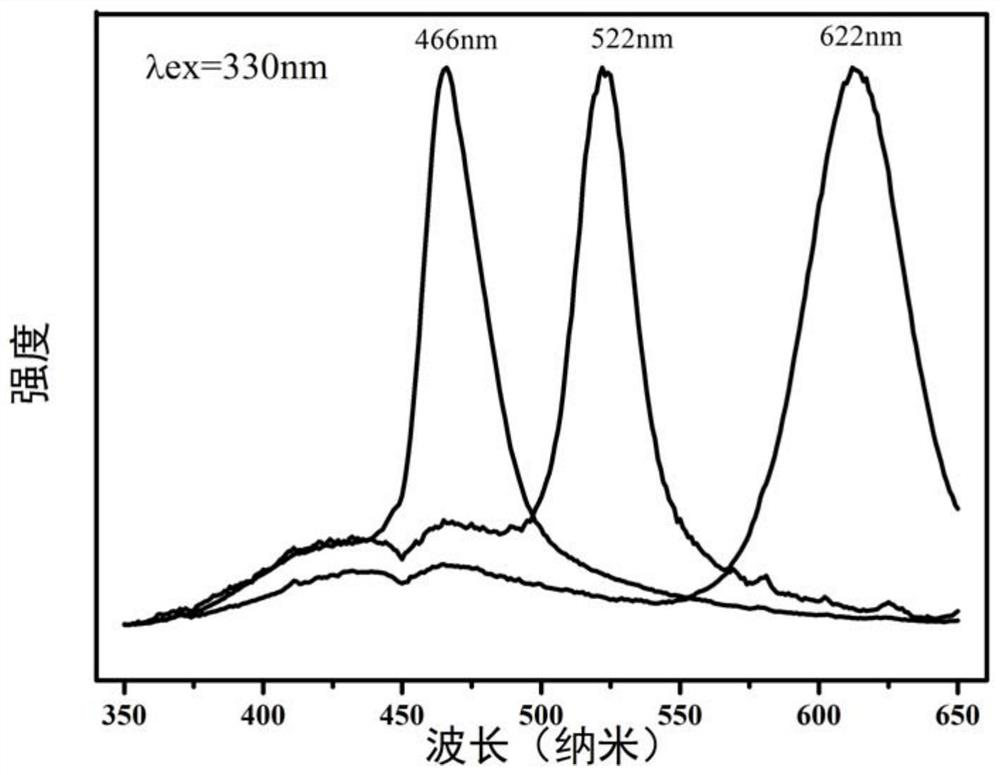

[0038] (1) Accurately weigh 5.2917gSiO 2 , 4.8860g H 3 BO 3 , 1.2110gNa 2 CO 3 , 0.3333gCaCO 3 , mix the above raw materials and grind them evenly in an agate mortar to obtain a precursor mixture. Put the precursor mixture in a crucible and heat it up to 1000°C at a rate of 8°C / min in a temperature-programmed box-type resistance furnace, then heat it up to 1550°C at a rate of 5°C / min and keep it for 2 hours, then pour it on a cooled iron plate The obtained glass is quickly transferred to an annealing furnace and kept at 450°C for 2 hours. Then the glass was ground, polished and placed in a muffle furnace at 590°C for 24 hours. Place the glass in 1mol / L NaOH solution for 15min and wash until neutral; put the glass in distilled water at 95°C for 12h; L of HCl solution and 1.5mol / L of NH 4 Cl solution in a mixed solution, and heated in a water bath at 95°C for 18 hours; put the acid-leached porous glass in distilled water again at 95°C for 24 hours, then wash it with dist...

Embodiment 3

[0043] (1) Accurately weigh 5.2065gSiO 2 , 5.0916g H 3 BO 3 , 0.9879gNa 2 CO 3 , 0.3333gCaCO 3 , mix the above raw materials and grind them evenly in an agate mortar to obtain a precursor mixture. Put the precursor mixture in a crucible and heat it up to 1000°C at a rate of 8°C / min in a temperature-programmed box-type resistance furnace, then heat it up to 1500°C at a rate of 5°C / min for 2 hours, then pour it on a cooled iron plate The obtained glass is quickly transferred to an annealing furnace and kept at 450°C for 2h. Then the glass was ground, polished and placed in a muffle furnace at 620°C for 24 hours. Place the glass in 1mol / L NaOH solution for 15min and wash until neutral; soak the glass in distilled water at 98°C for 12h; and place the pretreated glass in a 0.5mol / L ratio of 1:1 HCl solution and 0.5mol / L NH 4 Cl solution, and heated in a water bath at 98°C for 36 hours; soak the acid-leached porous glass in distilled water at 98°C for 24 hours, then wash wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com