Plastic foam forming device

A molding equipment and plastic foam technology, applied in the field of plastic molding, can solve the problems of low energy utilization rate, achieve the effect of lowering the temperature and accelerating the discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

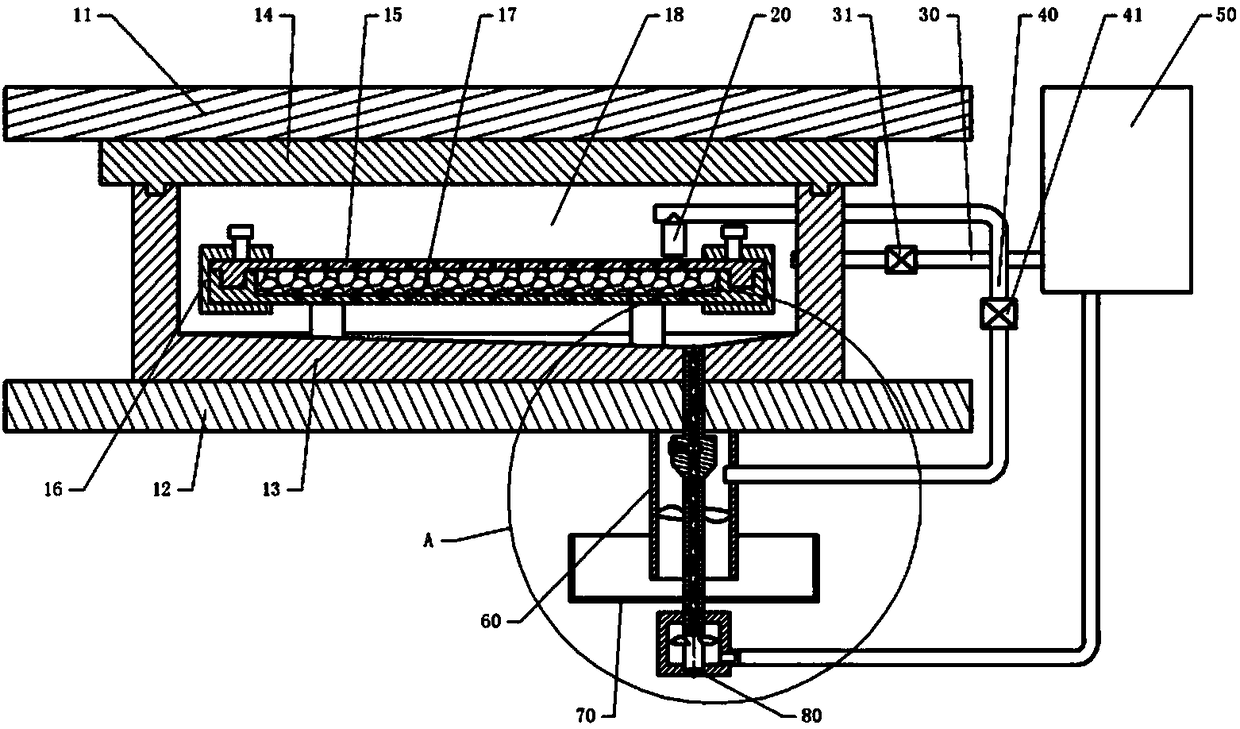

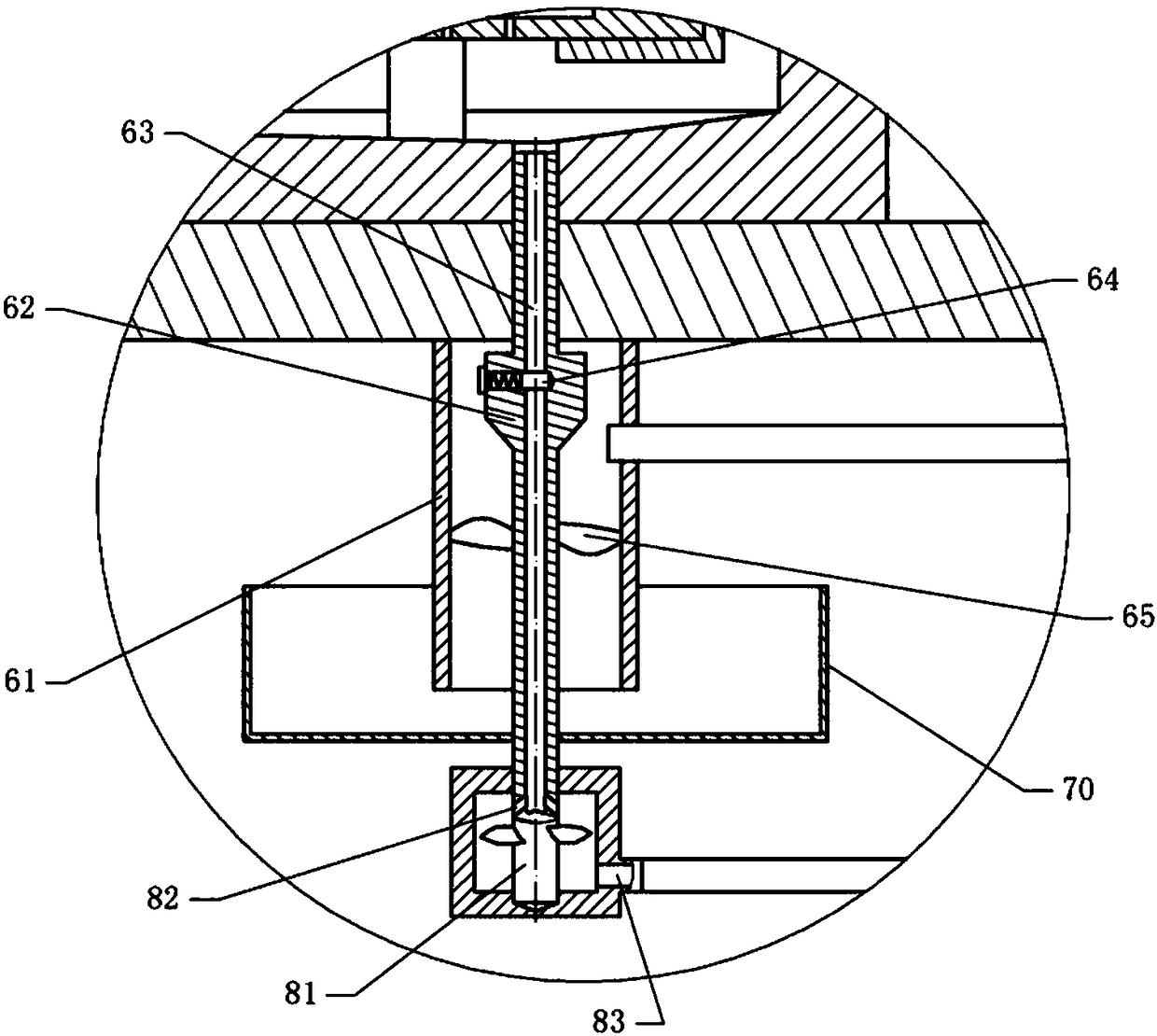

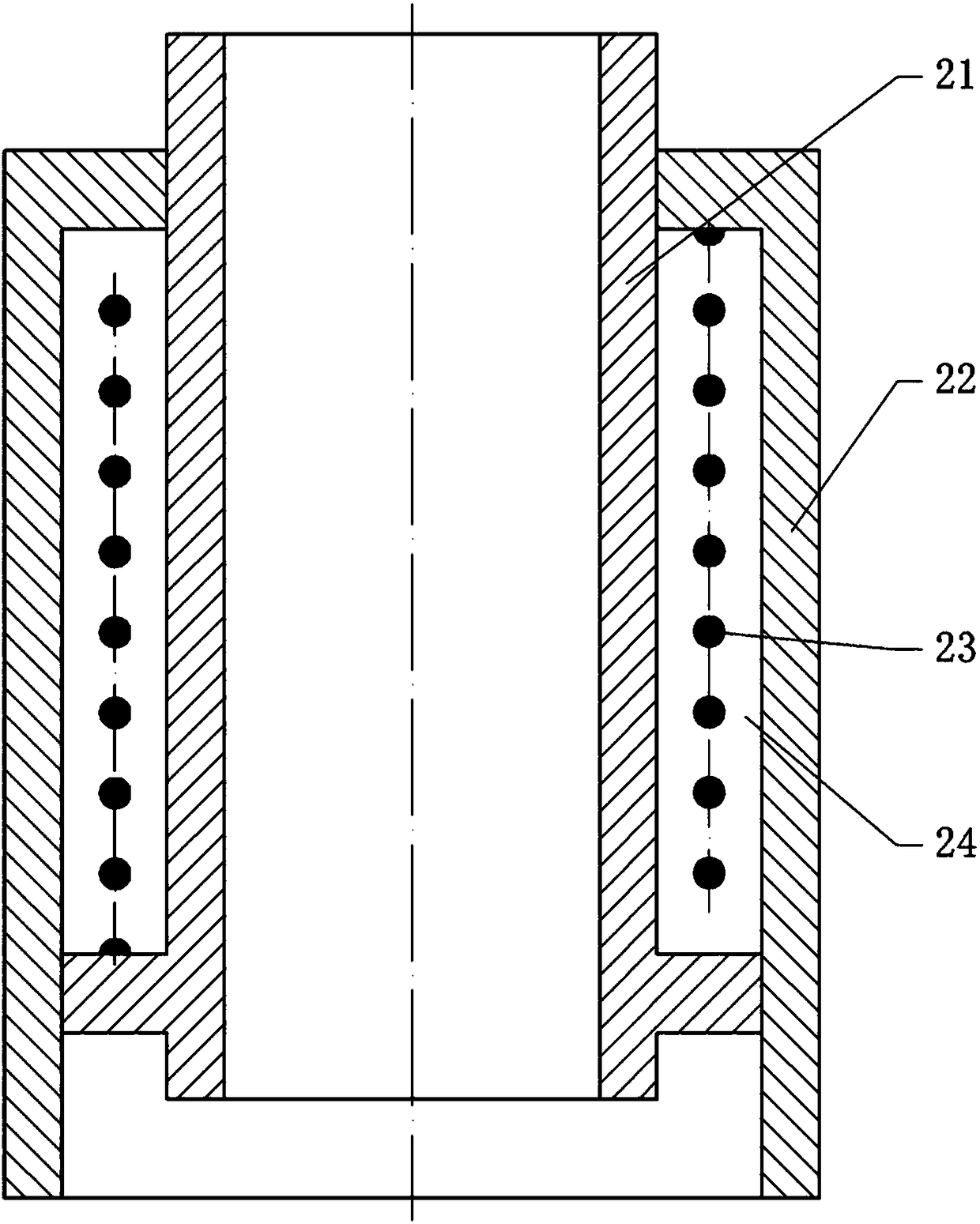

[0024] The reference signs in the accompanying drawings of the description include: upper hot pressing plate 11, lower hot pressing plate 12, water tank 13, cover plate 14, upper mold pressing plate 15, buckle 16, lower mold pressing groove 17, steam generator 18, Telescopic tube 20, inner tube 21, outer tube 22, extension spring 23, medium chamber 24, water inlet pipe 30, second stop valve 31, exhaust pipe 40, first stop valve 41, hot water tank 50, turbine mechanism 60, Pipe body 61, rotating shaft 62, guide channel 63, blocking block 64, turbine 65, cold water tank 70, pump body 80, input shaft 81, water inlet 82, water outlet 83.

[0025] The embodiment is basically as figure 1 , figure 2 and image 3 Shown:

[0026] The plastic foam molding equipment of the present embodiment comprises a two-layer hot press machine provided with an upper hot press plate 11 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com