Sludge crusher and method of crushing sludge with the same

A crusher and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as not easy to break, uneven particle size of sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the drawings herein are not drawn to scale in order to clearly show the contents, and that the same or similar reference numerals designate the same or similar parts or parts throughout the drawings. In addition, it should also be understood that any implementations described in this application and the technical features included in them can be combined with each other in an appropriate manner. It should be noted that in this application, the words "vertical" and "vertical direction" mean along the direction of gravity perpendicular to the ground, and the words "lateral", "horizontal" and "horizontal direction" all mean It means that the direction is perpendicular to the direction of gravity.

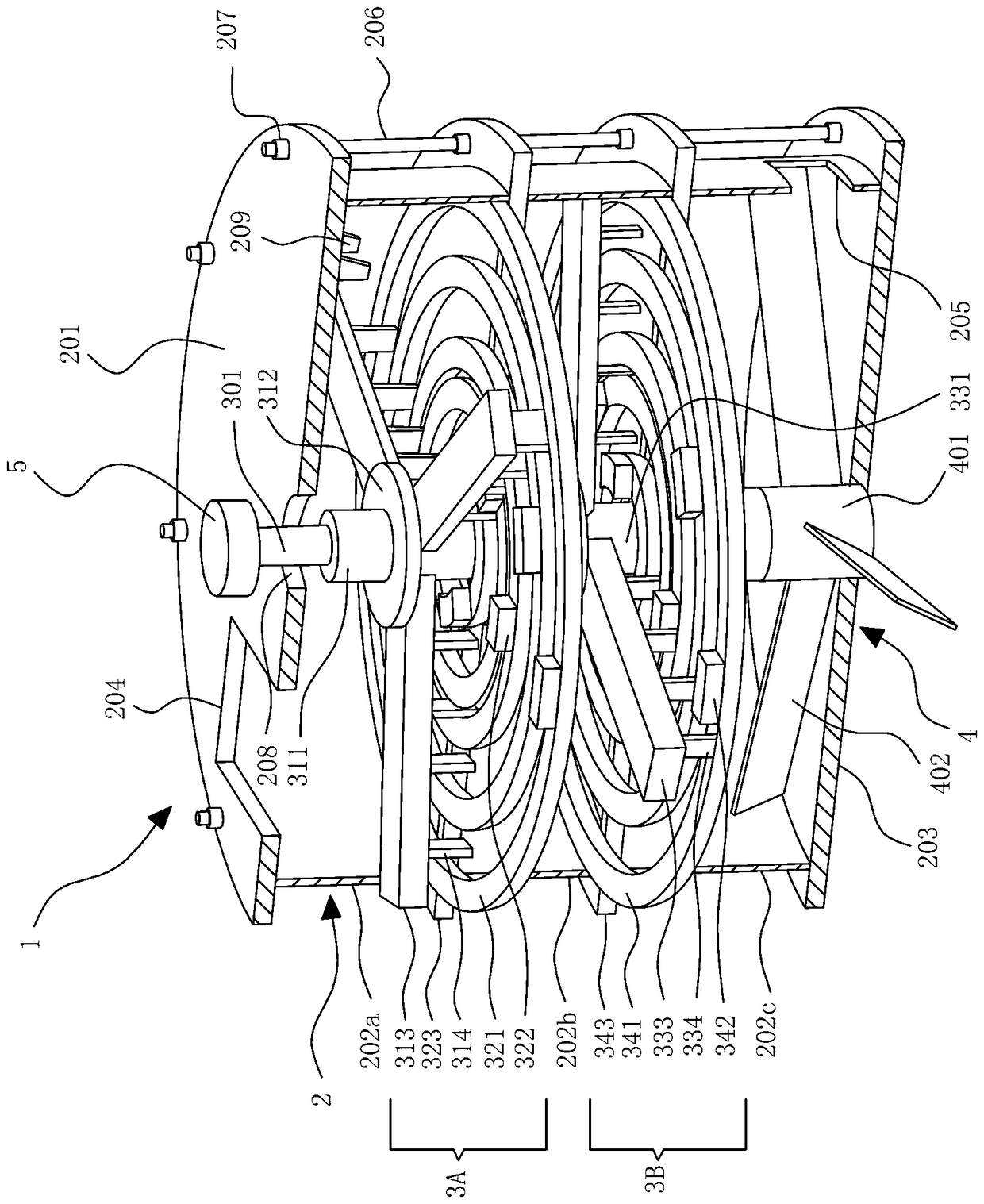

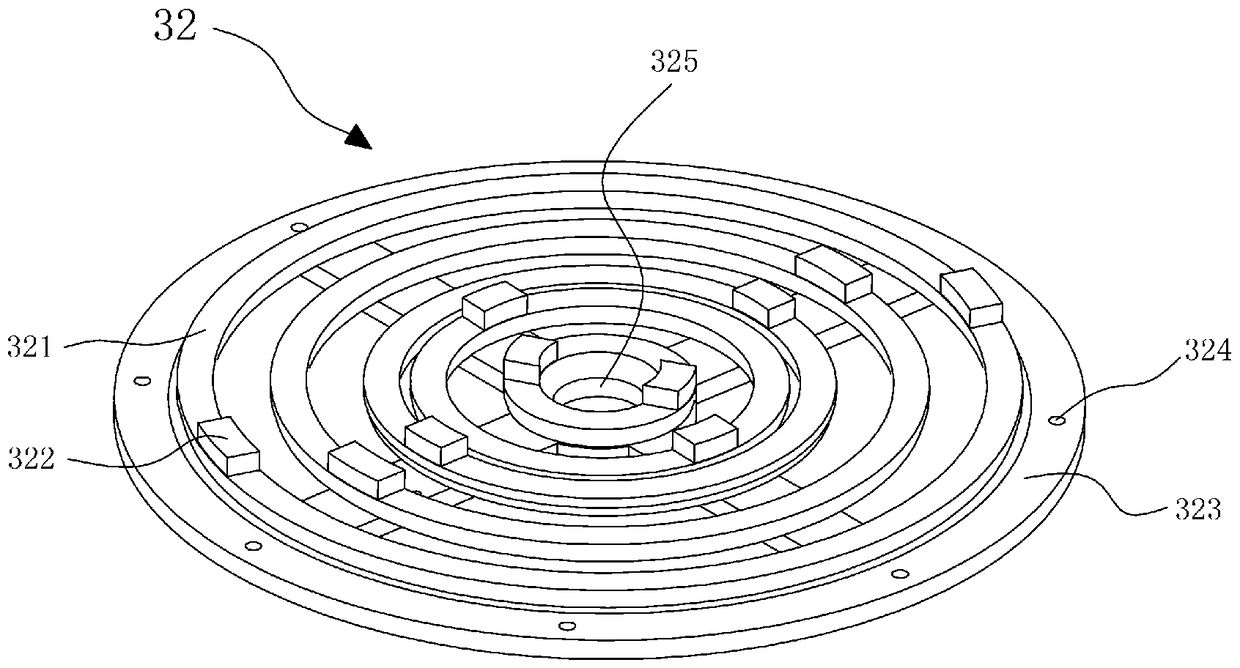

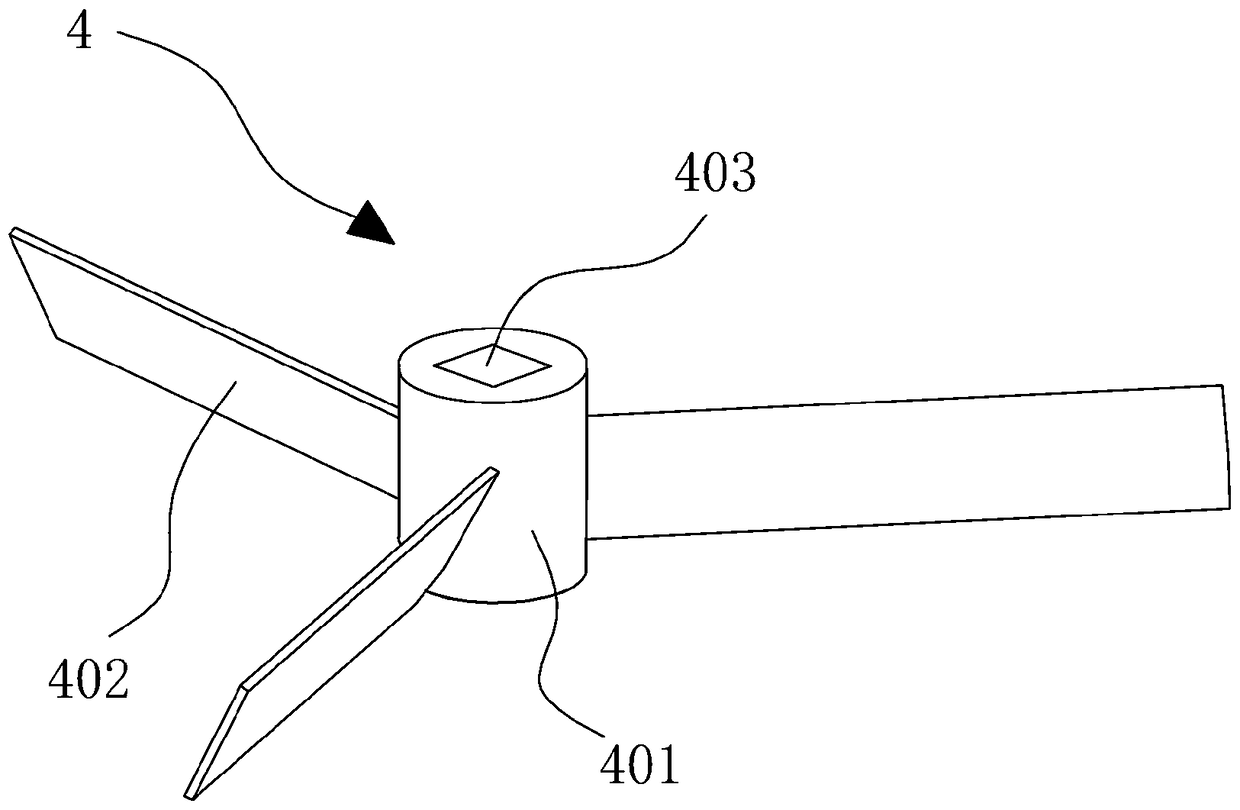

[0029] see now figure 1 and figure 2 ,in figure 1 An embodiment of the sludge breaker according to the present invention is shown in a perspective schematic view, figure 2 is figure 1 The three-dimensional schematic diagram of the sludge crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com