A polyionic liquid-based heteropolyacid catalyst for olefin epoxidation, preparation method and application thereof

A technology of polyionic liquid and epoxidation reaction, which is applied in the direction of physical/chemical process catalyst, catalytic reaction, organic compound/hydride/coordination complex catalyst, etc. It can solve the problems of low utilization rate and difficulty in catalytic recovery, etc. Achieve high utilization rate, mild reaction conditions, and realize the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

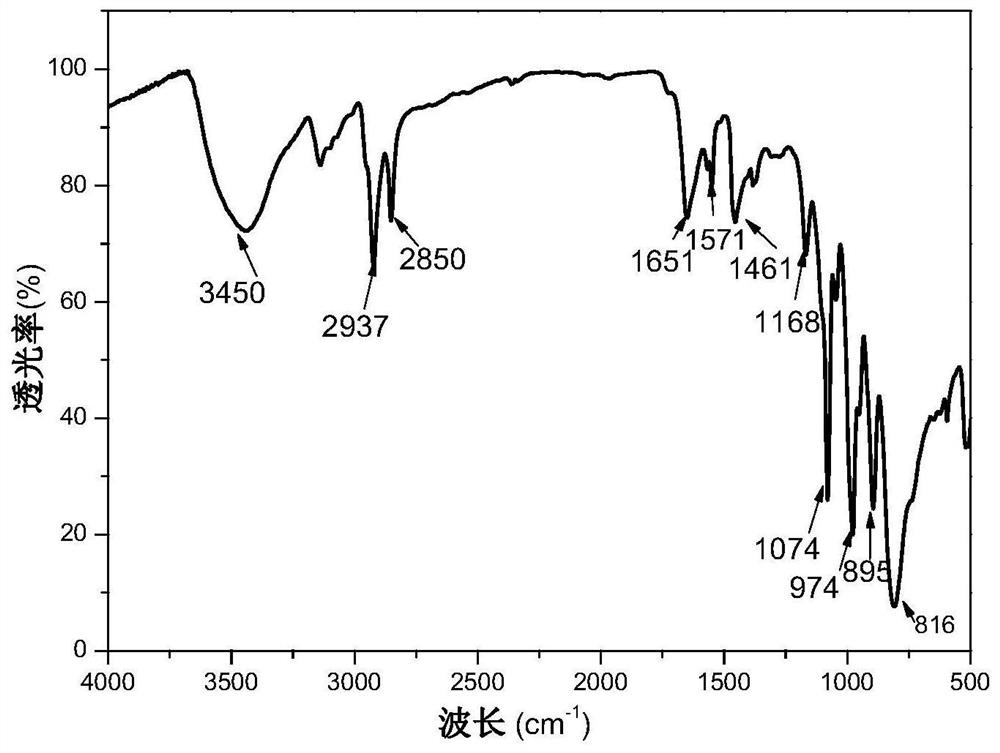

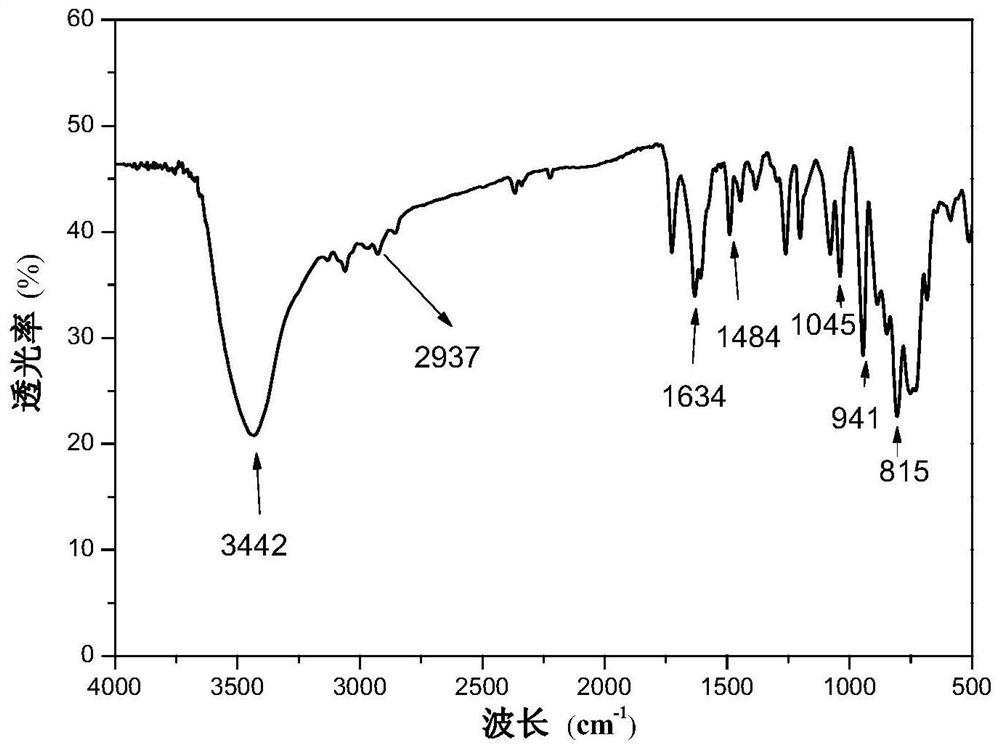

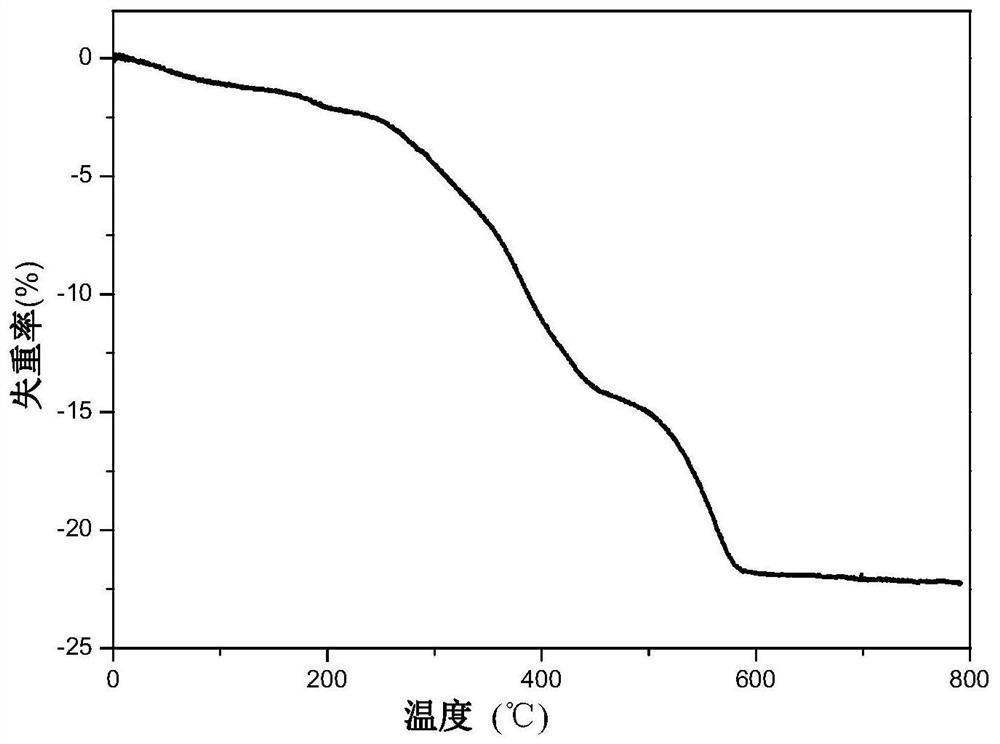

[0032] 1. Preparation of polyionic liquid-based heteropolyacid catalysts

[0033] (1) Preparation of piperidine functionalized ionic liquid

[0034] Weigh 9.89g of 1-vinylimidazole and 18.40g of N-(2-chloroethyl)piperidine hydrochloride respectively, add them to a 150ml flask, add 40ml of absolute ethanol, mix well, reflux under nitrogen and stir for 48h, After the reaction, it was cooled to room temperature to precipitate a white solid, which was filtered off with suction, washed with dichloromethane for 2-3 times, and dried at 80° C. for 2 hours to obtain white powdery solid particles of IMPD.

[0035] (2) Preparation of dodecane functionalized ionic liquid

[0036] Weigh 4.7592g (0.05mol) of 1-vinylimidazole and 12.5529g (0.05mol) of bromododecane, respectively, and add them to a 100ml round-bottomed flask, add 40ml of absolute ethanol, mix well, and reflux and stir under nitrogen protection. After 24 h, the solvent was evaporated by rotary evaporation to obtain a light y...

Embodiment 2

[0044] According to the application of the polyionic liquid-based heteropolyacid catalyst in Example 1, the reactants were changed, and the concrete method was as follows:

[0045] Weigh 1.08g of 10mmol of cyclooctene, 10ml of acetonitrile, and 0.1g of catalyst IMPD-IMDO-PW into a 25ml round-bottomed flask, place it in a 75°C water bath with a temperature controller, stir with a magnetic stirrer, and add it to the reaction system. Slowly add 8 mmol of hydrogen peroxide dropwise, and the dropwise addition ends the reaction for 5 h. After the reaction is completed, the mixture is centrifuged, the upper layer solution is taken to analyze its composition by gas chromatography, and the lower layer solid can be used for the next reaction after recovery. The catalyst recovery rate was 86%, the cyclohexene conversion rate was 100%, and the selectivity was 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com