Method for extracting lithium in waste lithium ion phosphate anode material

A technology of waste lithium iron phosphate and cathode material, which is applied in the direction of waste collector recycling, recycling technology, electrochemical generator, etc., can solve the problems of slow leaching speed, high recovery cost, poor leaching selectivity, etc. The effect of high energy utilization and heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

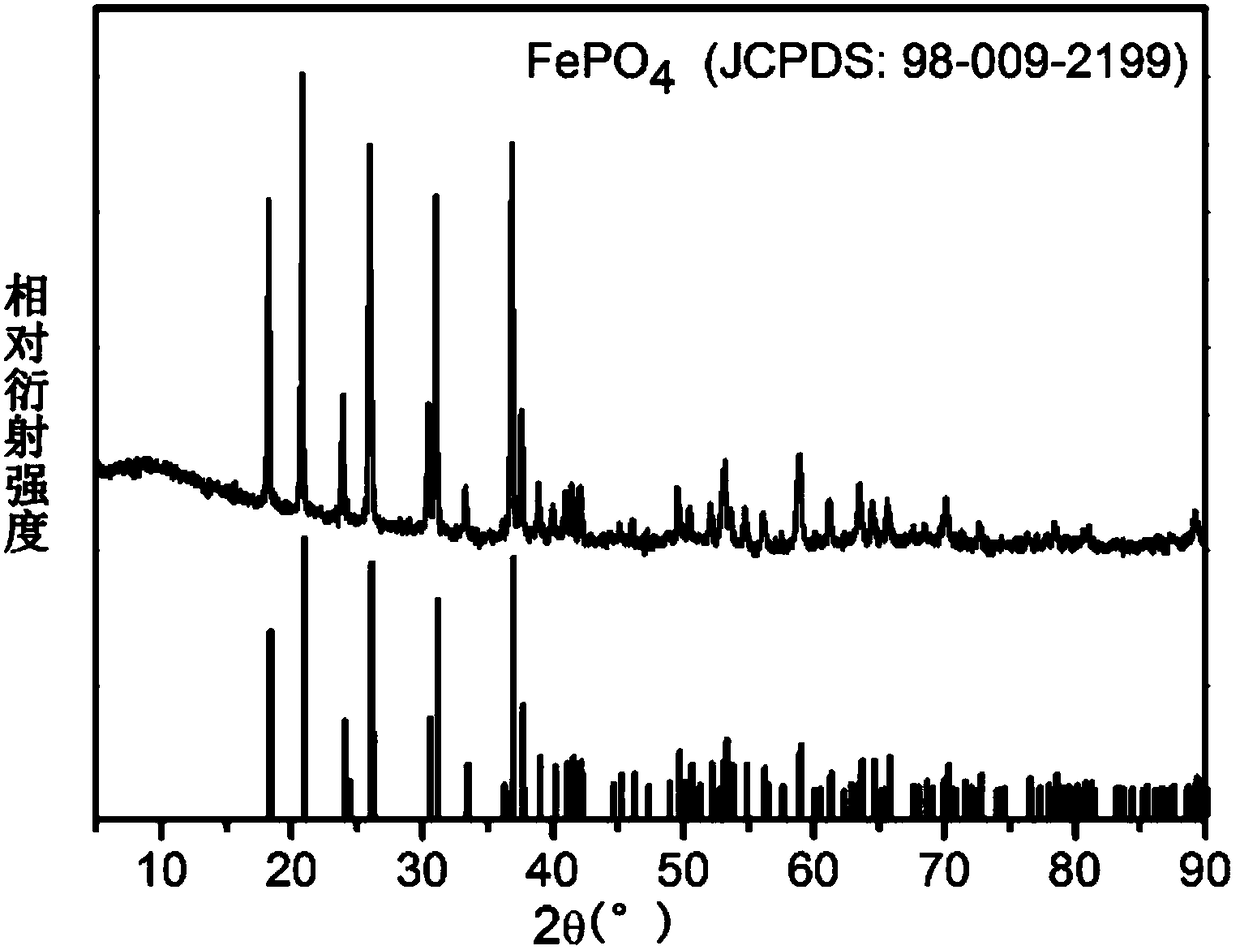

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for leaching lithium in waste lithium iron phosphate cathode material, the specific method is:

[0044] The raw material used in this example is waste lithium iron phosphate positive electrode production waste, which contains 3.7wt% of Li, 32.49wt% of Fe, 16.4wt% of P and 1.2wt% of Al in terms of weight percentage after mechanical crushing and pretreatment.

[0045] (1) Add the pretreated lithium iron phosphate positive electrode powder to the mixed solution of sulfuric acid and hydrogen peroxide for slurry adjustment (mix evenly) to obtain a mixed slurry, wherein the molar ratio of H / Li is 2, and the dosage of oxidant hydrogen peroxide is The molar ratio of the oxidant / Li is 3.0, and in the leaching reaction, the liquid-solid ratio of the volume of the leaching agent solution to the mass of the spent lithium iron phosphate positive electrode material is 1:1;

[0046] (2) Place the mixed slurry obtained after pulping in a microwave reac...

Embodiment 2

[0050] This embodiment provides a method for leaching lithium in waste lithium iron phosphate cathode material, the specific method is:

[0051] The raw material used in this example is waste lithium iron phosphate battery, and its main components are calculated by weight percentage after mechanical crushing and pretreatment, including Li 2.19%, Fe 26.51%, P 12.4%, Al 1.2%, Fe 2.10% and Cu 1.09%. .

[0052] (1) Add the pretreated lithium iron phosphate positive electrode powder into a mixed solution of acetic acid and sodium persulfate for slurry mixing (uniformly mixed) to obtain a mixed slurry, wherein the molar ratio of H / Li is 1.80, and the oxidizing agent is over The dosage of sodium sulfate is that the mol ratio of oxidant / Li is 1.0, and in the leaching reaction, the liquid-solid ratio of the volume of the leaching agent solution and the quality of the waste lithium iron phosphate cathode material is 10:1;

[0053] (2) Put the mixed slurry obtained after pulping in a mi...

Embodiment 3

[0056] This embodiment provides a method for leaching lithium in waste lithium iron phosphate cathode material, the specific method is:

[0057] The raw material used in this example is waste lithium iron phosphate battery, and its main components are calculated by weight percentage after mechanical crushing and pretreatment, including Li 2.19%, Fe 26.51%, P 12.4%, Al 1.2%, Fe 2.10% and Cu 1.09%. .

[0058] (1) Add the pretreated lithium iron phosphate positive electrode powder to the mixed solution of oxalic acid and hydrogen peroxide for slurry adjustment (mix evenly) to obtain a mixed slurry, wherein the molar ratio of H / Li is 1.0, and the dosage of oxidant hydrogen peroxide is The molar ratio of the oxidant / Li is 3.0, and in the leaching reaction, the liquid-solid ratio of the volume of the leaching agent solution to the mass of the spent lithium iron phosphate positive electrode material is 50:1;

[0059] (2) Put the mixed slurry obtained after pulping in a microwave rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com