A preparation method for realizing cu-doping of topological insulator bismuth selenide nanomaterials

A technology of topological insulators and nanomaterials, applied in nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems of inconvenience of topological superconductors, poor crystallinity of products, complicated processes, etc., and achieve low cost, high crystallinity, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

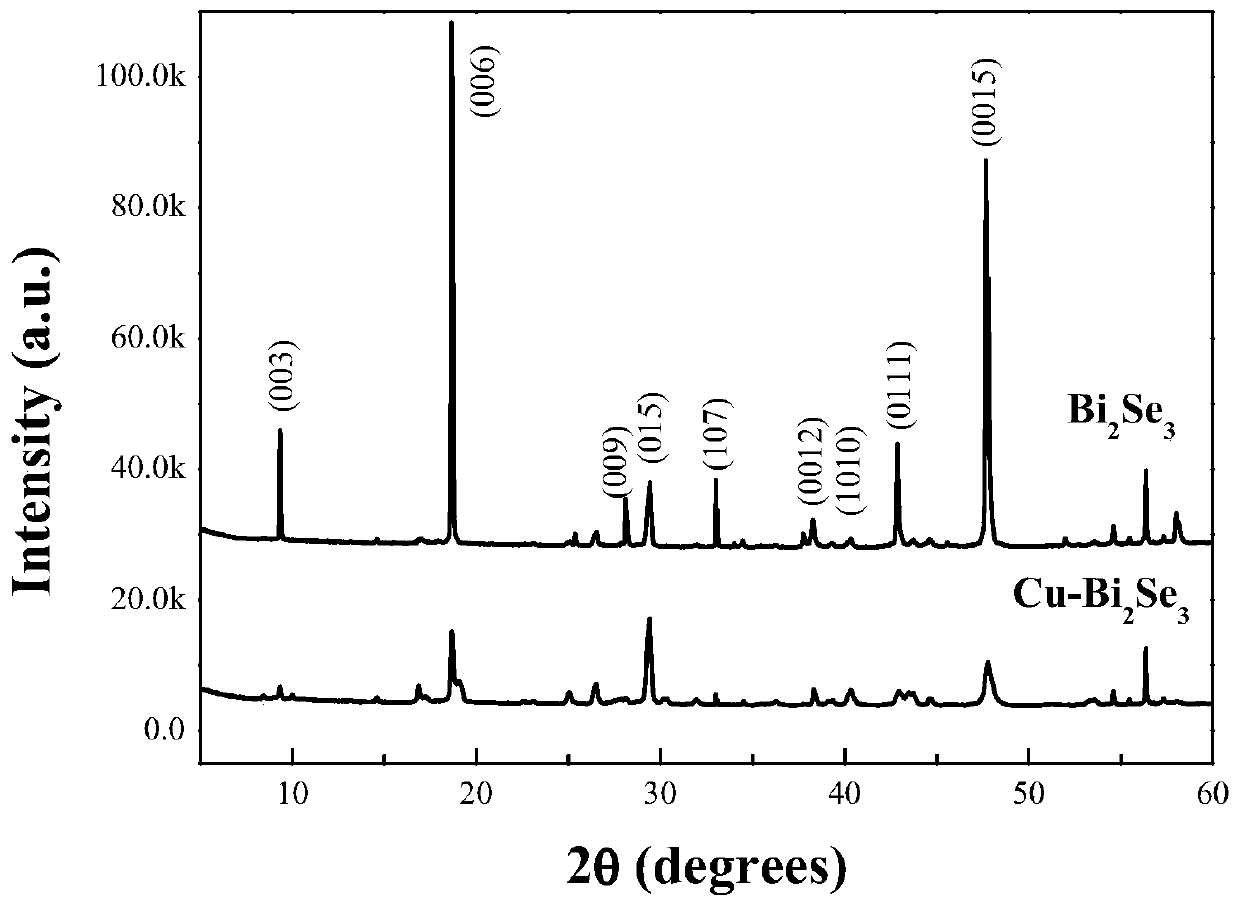

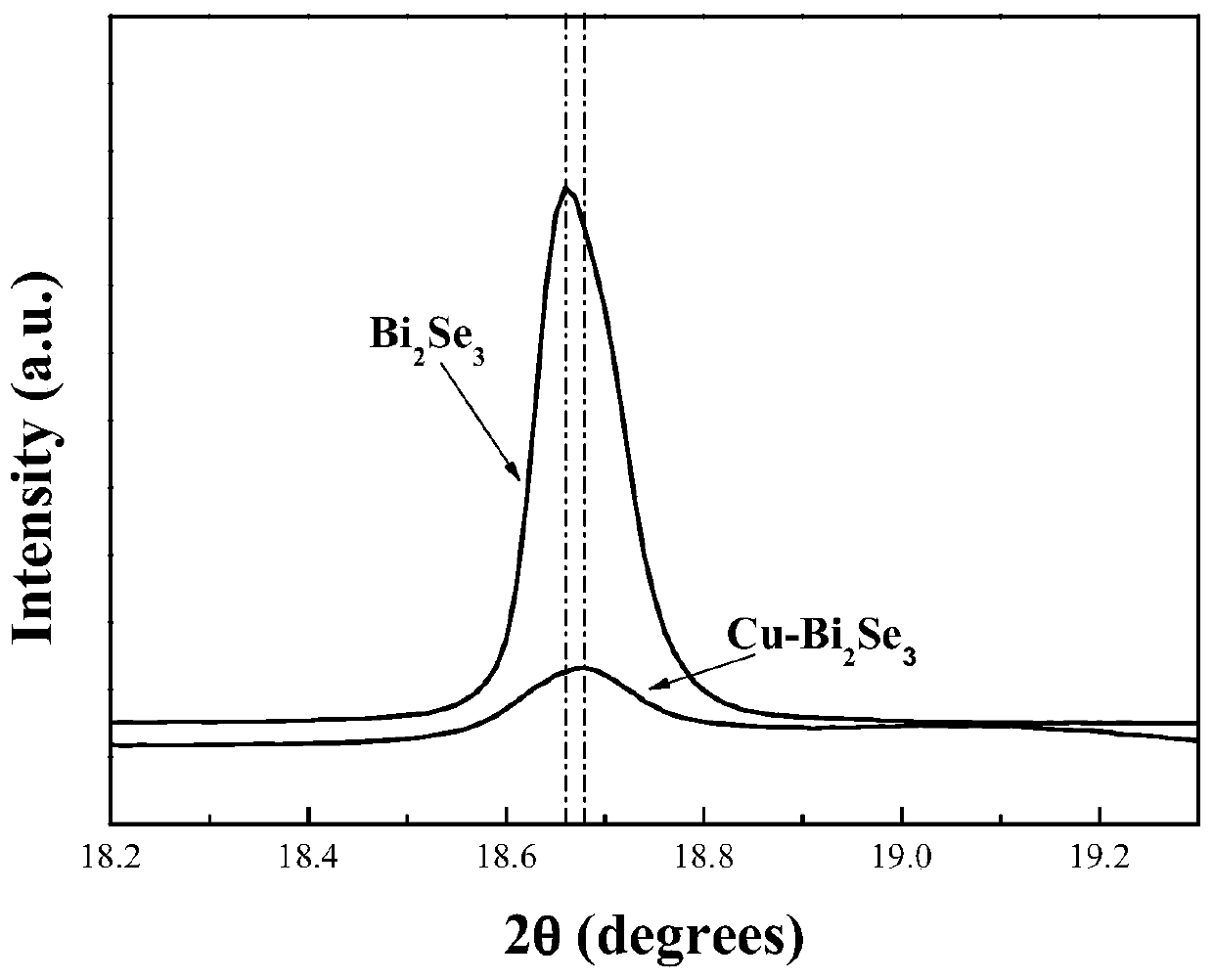

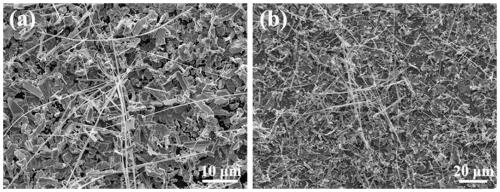

[0020] Prepare Cu-doped bismuth selenide nanomaterial according to the method provided by the invention, the steps are as follows:

[0021] (1) Clean SiO 2 / Si substrate, and use magnetron sputtering on SiO 2 Coating a layer of Cu film on the / Si substrate, and then coating a layer of Au film on the Cu film, the thickness of the Cu film and the Au film are both 10nm, as the Au / Cu catalyst;

[0022] (2) Place the cleaned quartz tube (with an inner diameter of 50 mm and a length of 1.5 m) horizontally in the tube furnace, and place bismuth selenide with a mass of 0.02 to 0.03 g and a weight ratio concentration of 99.999% at the heating center Powder (AlfaAsear), the SiO obtained in step (1) is placed at 8-14 cm away from the bismuth selenide powder in the downstream direction of the carrier gas 2 / Si substrate, sealed to the quartz tube, the sealing method is flange sealing, and vacuumized by a mechanical pump, the pressure is ≤130Pa;

[0023] (3) Heat the tube furnace in ste...

Embodiment 2

[0030] Prepare Cu-doped bismuth selenide nanomaterial according to the method provided by the invention, the steps are as follows:

[0031] (1) Clean SiO 2 / Si substrate, and use magnetron sputtering on SiO 2 Coating a layer of Cu film on the / Si substrate, and then coating a layer of Au film on the Cu film, the thickness of the Cu film and the Au film are both 10nm, as the Au / Cu catalyst;

[0032] (2) Place the cleaned quartz tube (with an inner diameter of 50 mm and a length of 1.5 m) horizontally in the tube furnace, and place bismuth selenide with a mass of 0.02 to 0.03 g and a weight ratio concentration of 99.999% at the heating center Powder (AlfaAsear), the SiO obtained in step (1) is placed at 8-14 cm away from the bismuth selenide powder in the downstream direction of the carrier gas 2 / Si substrate, sealed to the quartz tube, the sealing method is flange sealing, and vacuumized by a mechanical pump, the pressure is ≤130Pa;

[0033] (3) Heat the tube furnace in ste...

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the heating temperature in step (3) is set to 600° C., and the others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com