Preparation method of composite ceramic coating for surface of carbon/carbon composite

A technology of carbon composite material and surface compounding, which is applied in the field of aerospace to achieve the effect of tight combination, simple preparation method, strong oxidation resistance and ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

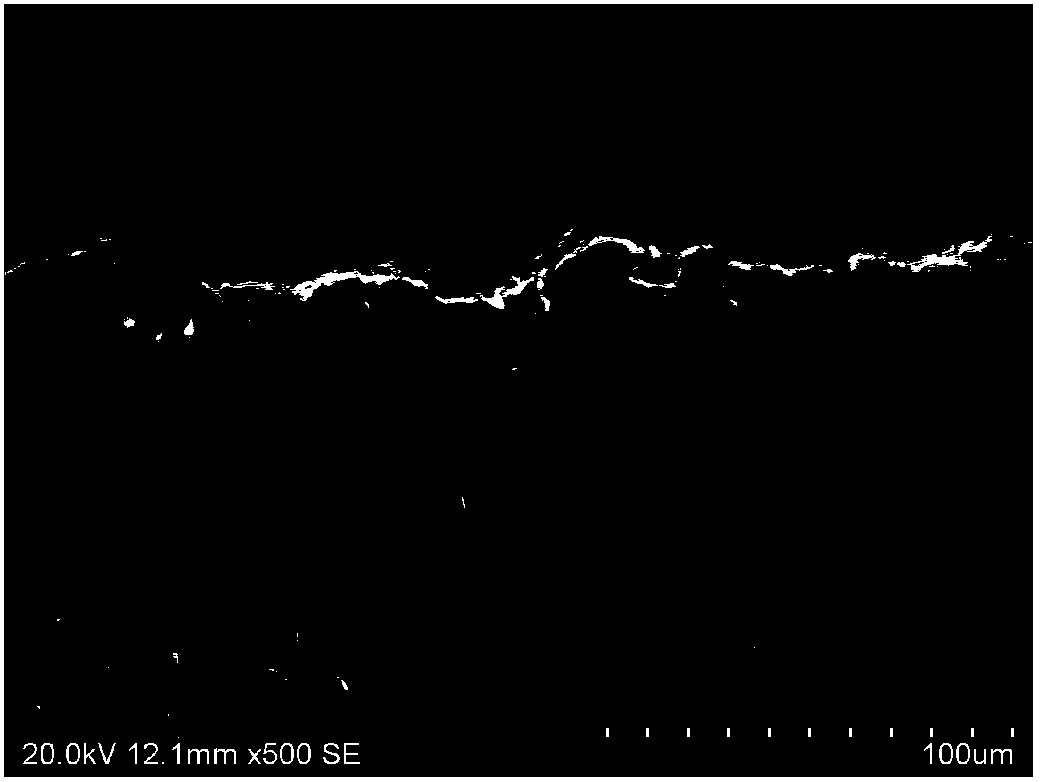

Image

Examples

Embodiment 1

[0062] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material includes the following steps:

[0063] Step 1, SiC-MoSi on the surface of carbon / carbon composite 2 Pre-coating preparation:

[0064] (1) Take 5g Si powder, 3.5g SiC powder and 13.5g MoSi according to the material ratio of 2:1:1 2 The powder is mixed to form the raw material powder, and polyvinyl alcohol-200 is added. The added amount of the polyvinyl alcohol-200 is 8.3% of the raw material powder according to the mass ratio. The raw material powder and the binder are ground for 30 minutes and mixed to form a mixture , Among them, Si powder, SiC powder and MoSi 2 The particle size of the powder is 75μm;

[0065] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.0g / mL. After standing for 20 minutes, stir again to evenly coat the suspension on the surface of the C / C composite material. Form a pre-coating with a thickness of 0.6mm;

...

Embodiment 2

[0072] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material includes the following steps:

[0073] Step 1, SiC-MoSi on the surface of carbon / carbon composite 2 Pre-coating preparation:

[0074] (1) Take 5.7g Si powder, 4.1g SiC powder and 15.5g MoSi according to the material ratio of 2:1:1 2 The powder is mixed to form the raw material powder, and polyvinyl alcohol-200 is added. The added amount of the polyvinyl alcohol-200 is 9.0% of the raw material powder according to the mass ratio. The raw material powder and the binder are ground for 30 minutes and mixed to form a mixture , Among them, Si powder, SiC powder and MoSi 2 The particle size of the powder is 100μm;

[0075] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.5g / mL, let it stand for 25 minutes and stir again to evenly coat the surface of the C / C composite material. Form a pre-coating layer with a thickness of 0.7mm;

[0076] S...

Embodiment 3

[0082] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material includes the following steps:

[0083] Step 1, SiC-MoSi on the surface of carbon / carbon composite 2 Pre-coating preparation:

[0084] (1) Take 6.4g Si powder, 4.5g SiC powder and 17.4g MoSi according to the material quantity ratio of 2:1:1 2 The powder is mixed to form the raw material powder, and polyvinyl alcohol-600 is added. The added amount of the polyvinyl alcohol-600 is 9.3% of the raw material powder according to the mass ratio. The raw material powder and the binder are ground for 30 minutes and mixed to form a mixture , Among them, Si powder, SiC powder and MoSi 2 The particle size of the powder is 120μm;

[0085] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.5g / mL, let it stand for 25 minutes and stir again to evenly coat the surface of the C / C composite material. Form a pre-coating layer with a thickness of 0.8mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com