Injection molding method for plate grids

A grid and mold cavity technology, which is applied in the field of battery processing, can solve problems such as poor fluidity, high surface tension of mixed materials, and unclear edges and corners of the grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below by means of specific embodiments:

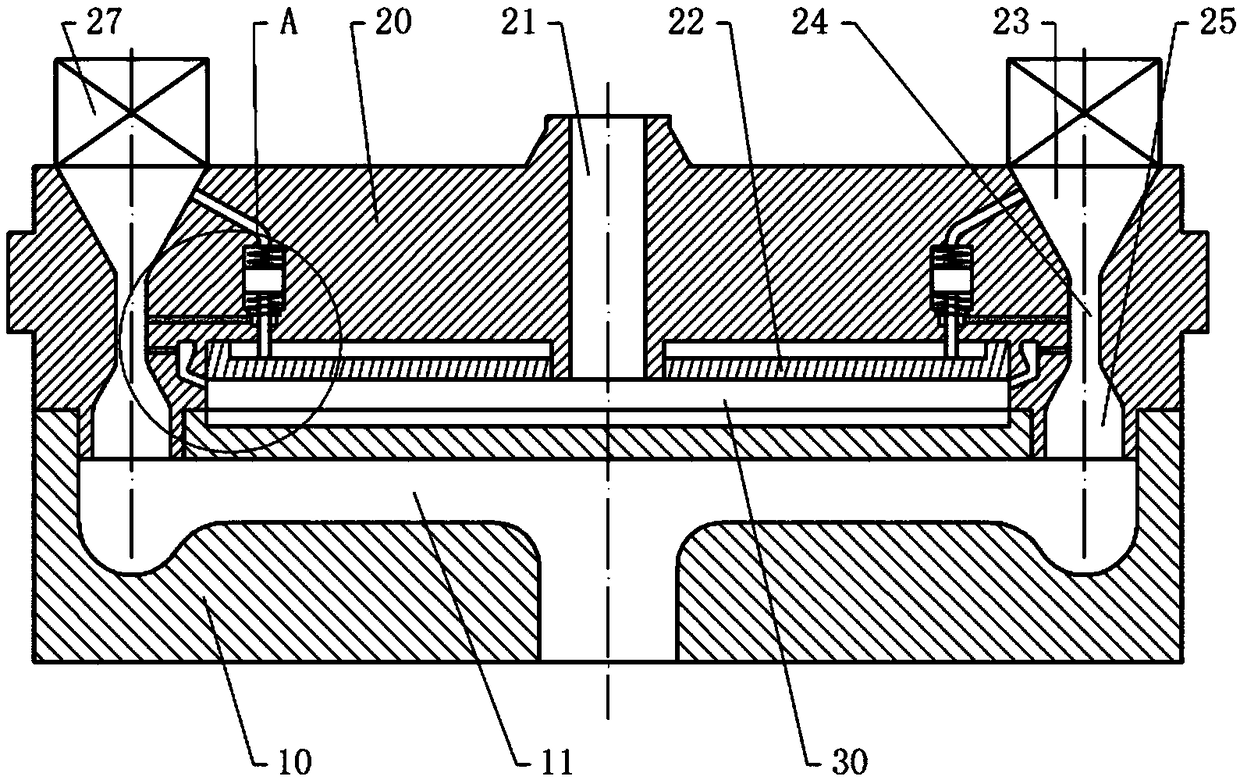

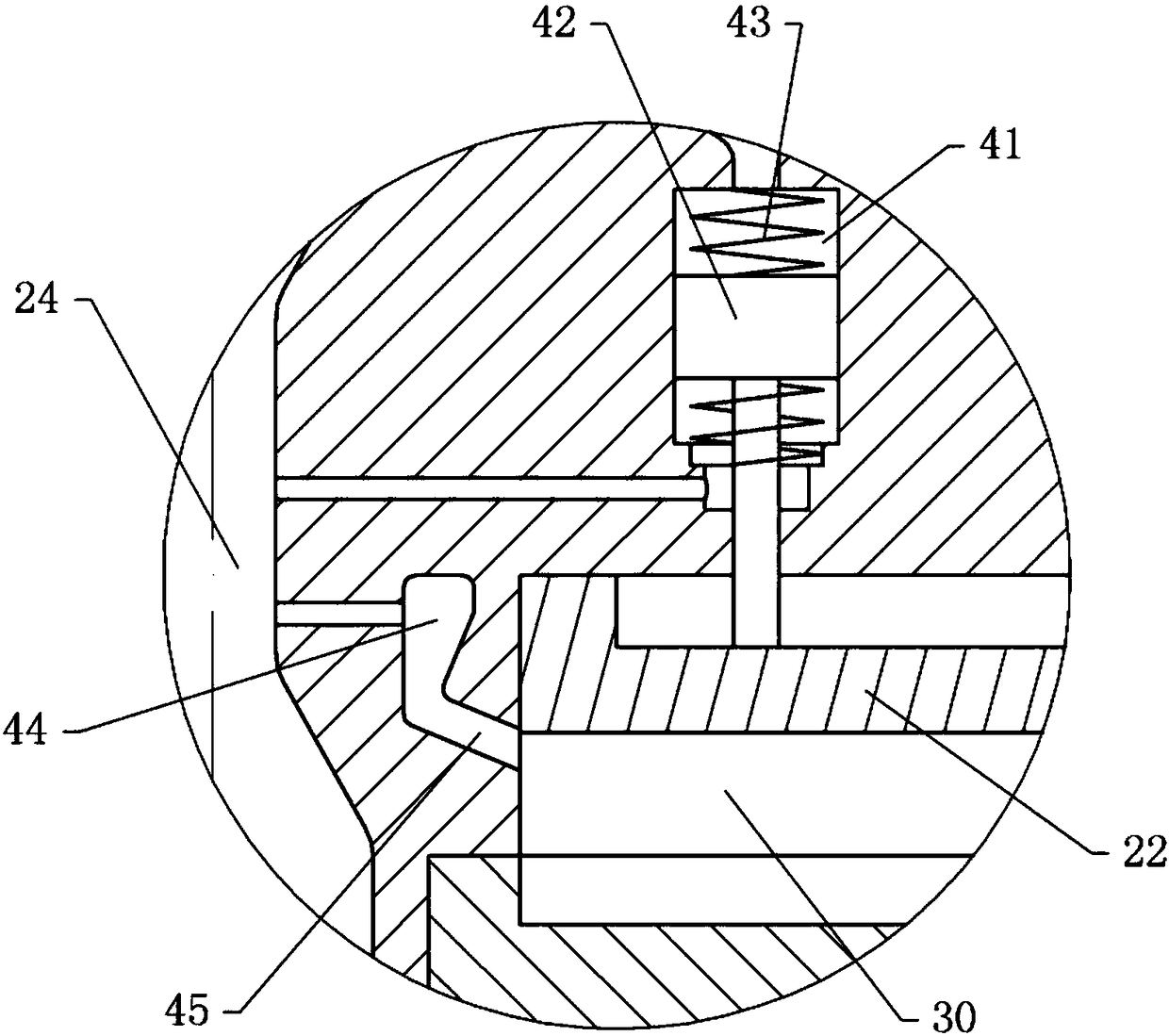

[0032] The reference signs in the drawings of the description include: lower mold 10, water flow cooling channel 11, upper mold 20, injection port 21, template 22, inlet section 23, throat 24, diffusion section 25, two-position two-way electromagnetic reversing valve 27. Die cavity 30, pressure chamber 41, piston 42, balance spring 43, residual material chamber 44, wedge mouth 45.

[0033] The injection molding method of the grid in this embodiment uses an injection molding device to inject the grid. like figure 1 , figure 2 As shown, the injection molding equipment includes an injection molding machine, an upper mold 20 and a lower mold 10, and the upper mold 20 and the lower mold 10 are fixed to each other by bolts, so that the upper mold 20 and the lower mold 10 are detachable. The upper mold 20 is provided with an air flow cooling passage, and the lower mold 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com