Crab apple enzyme and preparation method thereof

A technology of sand fruit and enzyme is applied in the direction of bacteria, yeast-containing food ingredients, food ingredients used in food preparation as taste improvers, etc., which can solve problems such as unfavorable and reasonable diet, inability to fully extract and release natural active ingredients, etc. The effect of body immunity, regulating human intestinal balance, regulating intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

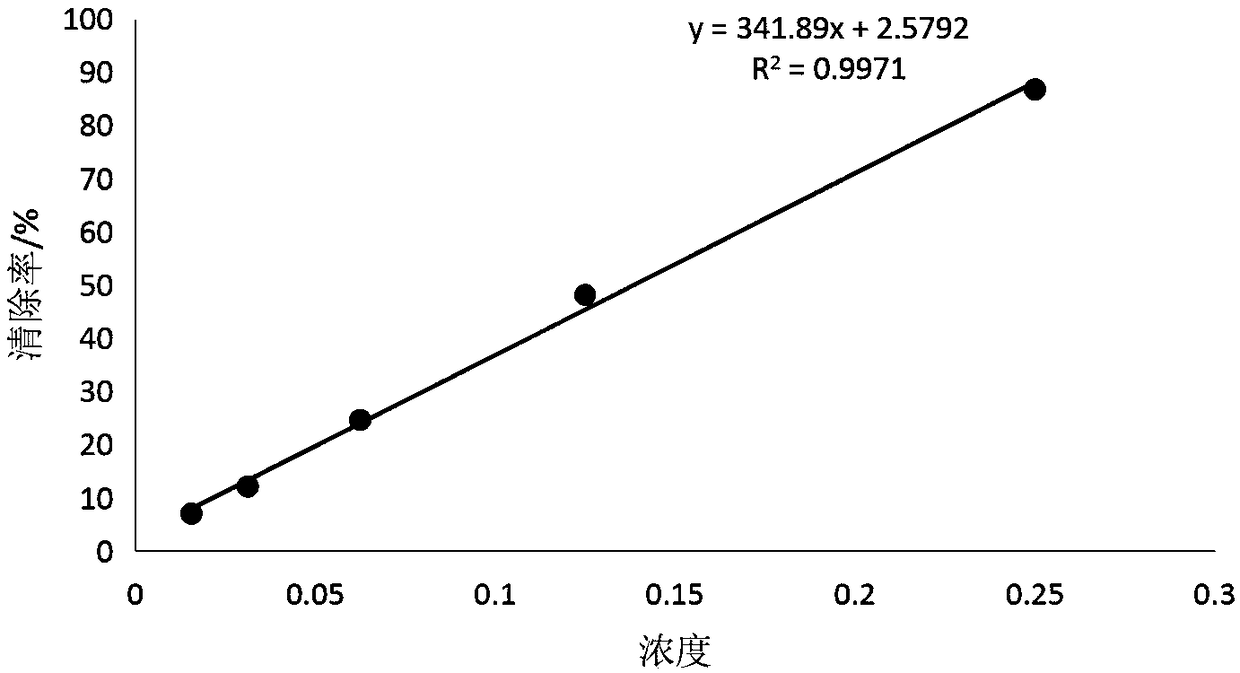

Image

Examples

preparation example Construction

[0034] This embodiment discloses a kind of sand fruit enzyme and a kind of preparation method of sand fruit enzyme, and the preparation method comprises the following steps:

[0035] S101: After the fruit pretreatment, the fruit pulp is prepared, and the fruit pulp is enzymatically hydrolyzed with pectinase to obtain an enzymatic solution; because fruit contains more pectin, the fruit pulp is subjected to pectinase Enzymatic hydrolysis; the pretreatment steps of sand fruit: wash the picked sand fruit with pure water, and dry at 30-50°C. The step of preparing sago pulp: take the pretreated sago, crush and beat it with a juice extractor. Adding pectinase is 1-5‰ of the weight of the sand fruit pulp; the sand fruit pulp is enzymatically hydrolyzed by pectinase method: 30-50°C, 100-200rpm stirring, pH3.5-5.5, enzymolysis time 2-4h The sand fruit selected for use is not damaged and rotten, fully ripe, and the fruit skin is red sand fruit.

[0036] Choose sand fruit as the main ra...

Embodiment 1

[0046] In terms of mass percentage, the Shaguo enzyme is composed of the following raw materials: 92% of Shaguo, 6% of fermentation auxiliary materials and 2% of functional sugar.

[0047] Preparation:

[0048] Fruit pretreatment. Take pure water to wash the picked sand fruits, and dry them at 40°C.

[0049] Preparation of sand fruit pulp. Take the sand fruit of step (1), and use a juice extractor to crush and make a pulp.

[0050] enzymolysis. Shaguo pulp was stirred at 150rpm for 5‰ pectinase enzymolysis at a temperature of 30°C, pH 4.0, and enzymolysis time of 2h.

[0051] Treatment before fermentation. Add fermented adjuvant in Shaguo pulp as follows in weight percentage:

[0053] Food grade soybean flour 2%

[0054] Shaguo pulp is adjusted to a pH value of 5.5 after adding fermentation auxiliary materials.

[0055] Sterilize. Take the Shaguo pulp from step (4) and sterilize at 80°C for 20 minutes.

[0056] Probiotic fermentation....

Embodiment 2

[0065] In terms of mass percentage, the Shaguo enzyme is composed of the following raw materials: 90% of Shaguo, 8% of fermentation auxiliary materials, and 2% of functional sugar.

[0066] Preparation:

[0067] Fruit pretreatment. Take pure water to wash the picked sand fruits, and dry them at 30°C.

[0068] Preparation of sand fruit pulp. Take the sand fruit of step (1), and use a juice extractor to crush and make a pulp.

[0069] enzymolysis. Shaguo pulp was stirred at 100 rpm for 3‰ pectinase enzymatic hydrolysis at a temperature of 50°C, pH 5.0, and enzymatic hydrolysis time of 2 hours.

[0070] Treatment before fermentation. Add fermented adjuvant in Shaguo pulp as follows in weight percentage:

[0071] Food Grade Peptone 8%

[0072] Shaguo pulp is adjusted to a pH value of 6.0 after adding fermentation auxiliary materials.

[0073] Sterilize. Take the Shaguo pulp from step (4) and sterilize at 100°C for 10 minutes.

[0074] Probiotic fermentation. The sterili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com