PMSM (permanent magnet synchronous motor) control device and method based on single current sensor

A technology of permanent magnet synchronous motor and control device, which is applied in the direction of motor generator control, electronic commutation motor control, motor control, etc., can solve the problems of high cost of control device, complicated control method, and large number of sensors, and achieve volume and The effect of cost reduction, avoiding disturbance and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

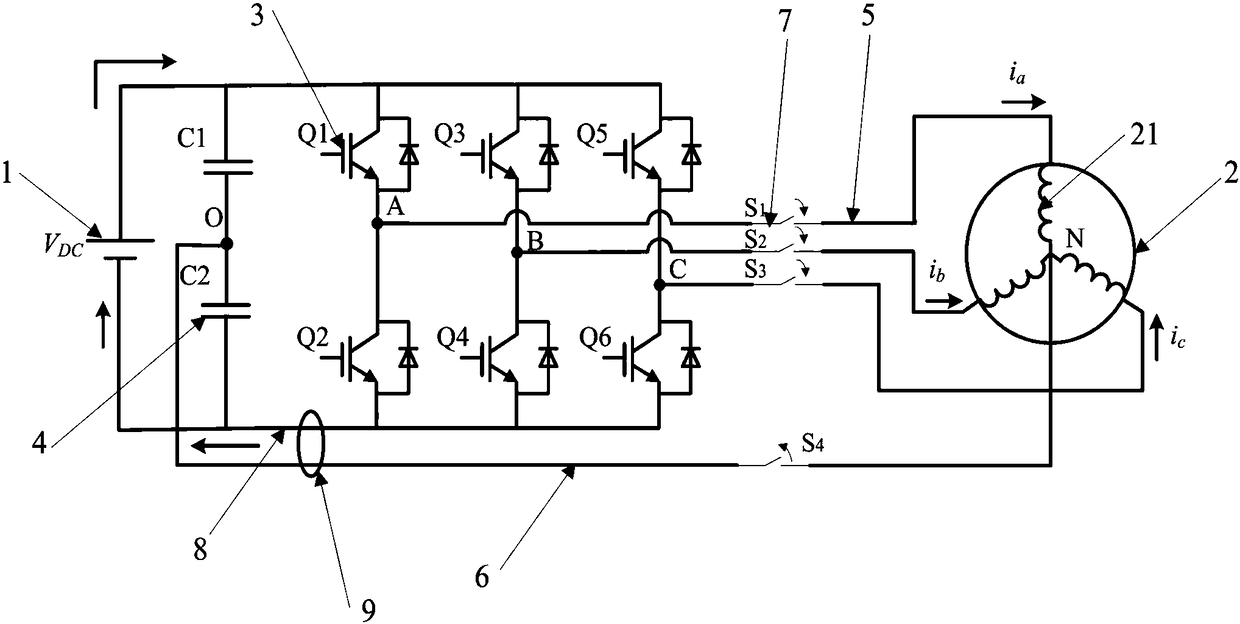

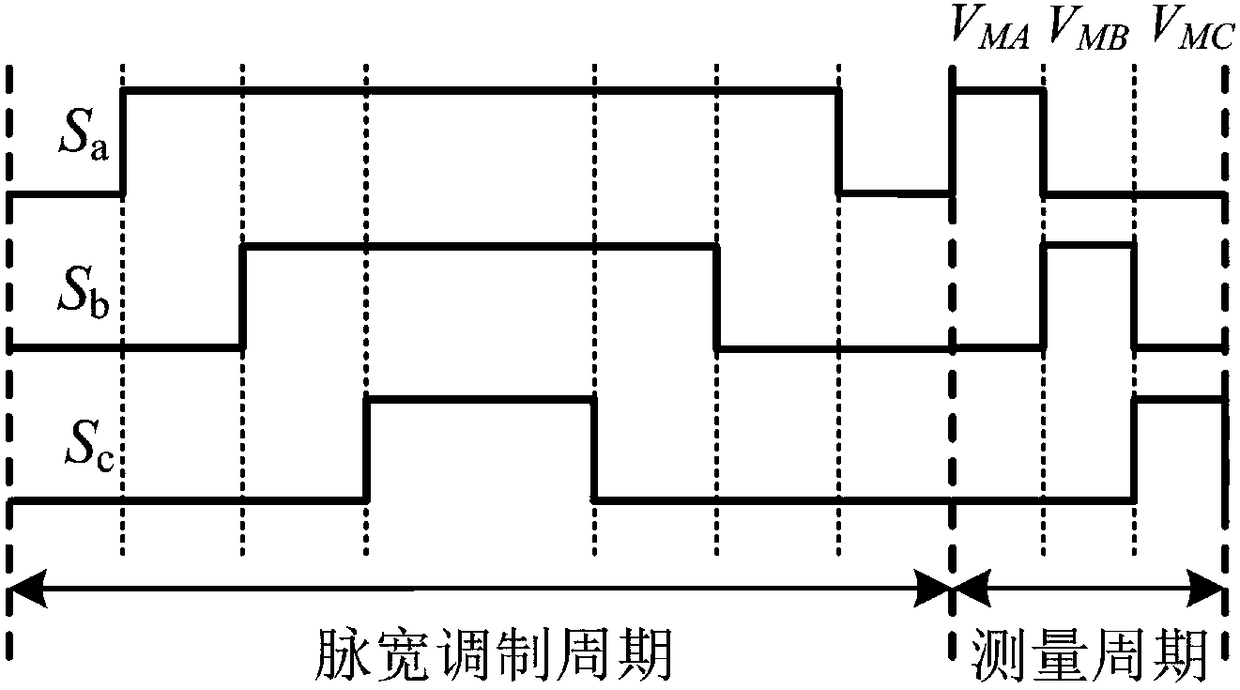

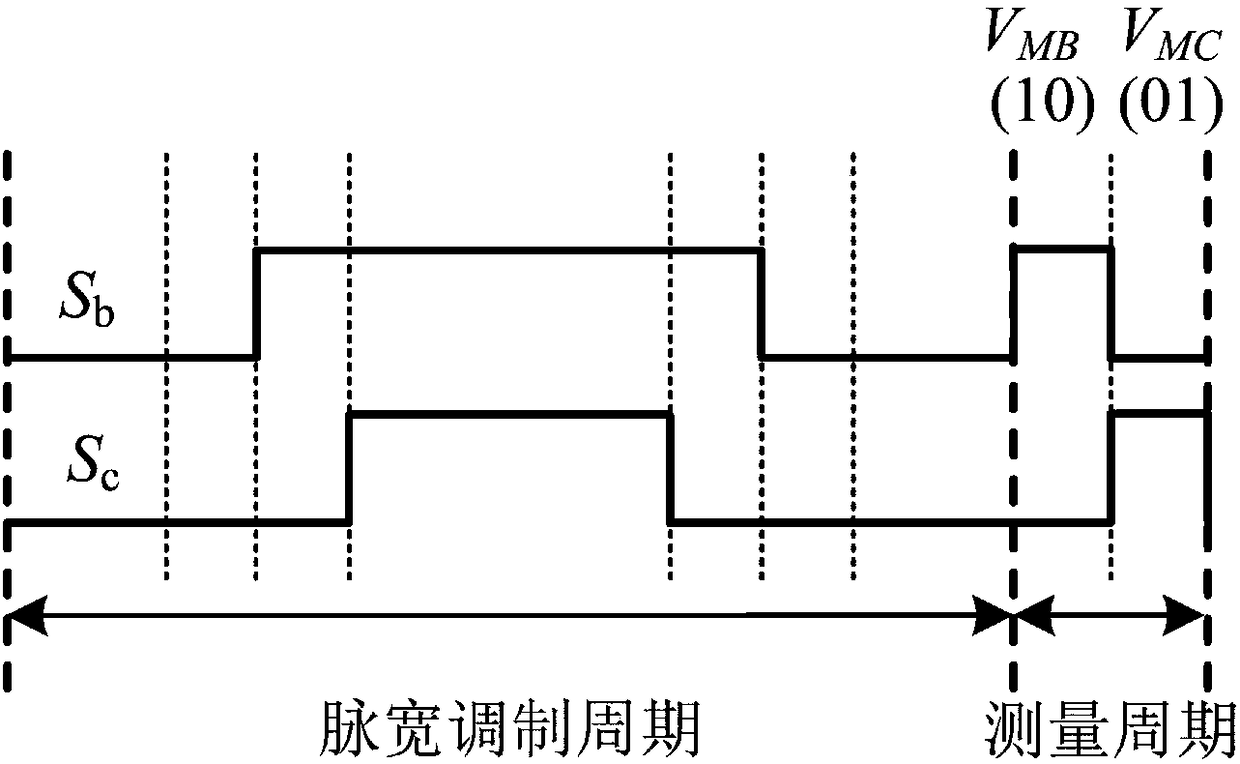

[0027] Such as Figures 1 to 10 As shown, a permanent magnet synchronous motor control device based on a single current sensor includes a permanent magnet synchronous motor 2 connected to a power source 1. The permanent magnet synchronous motor is provided with three-phase windings, which are A phase, B phase and C phase in turn. One end of the three-phase winding intersects at a point N, which is the center point of the three-phase winding 21; outside the power supply, there are four "mouth-shaped" branches in sequence from left to right, and one end of each branch is connected to the power supply 1 connected to the positive pole of the power supply, and the other end is connected to the negative pole of the power supply; the four branches are the voltage dividing branch and the three phase-splitting branches of A phase, B phase and C phase in turn. Two capacitors 4 are provided with inverter switching tubes 3 on each phase-splitting branch of the three-phase branch; each pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com