Short-circuit compensation control method of four-phase permanent-magnetic fault-tolerant motor

A permanent magnet fault-tolerant and consistent technology, applied in the direction of AC motor control, single motor speed/torque control, control system, etc., can solve problems such as difficult software programming and complex algorithms, and achieve the effect of short-circuit fault fault-tolerant control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

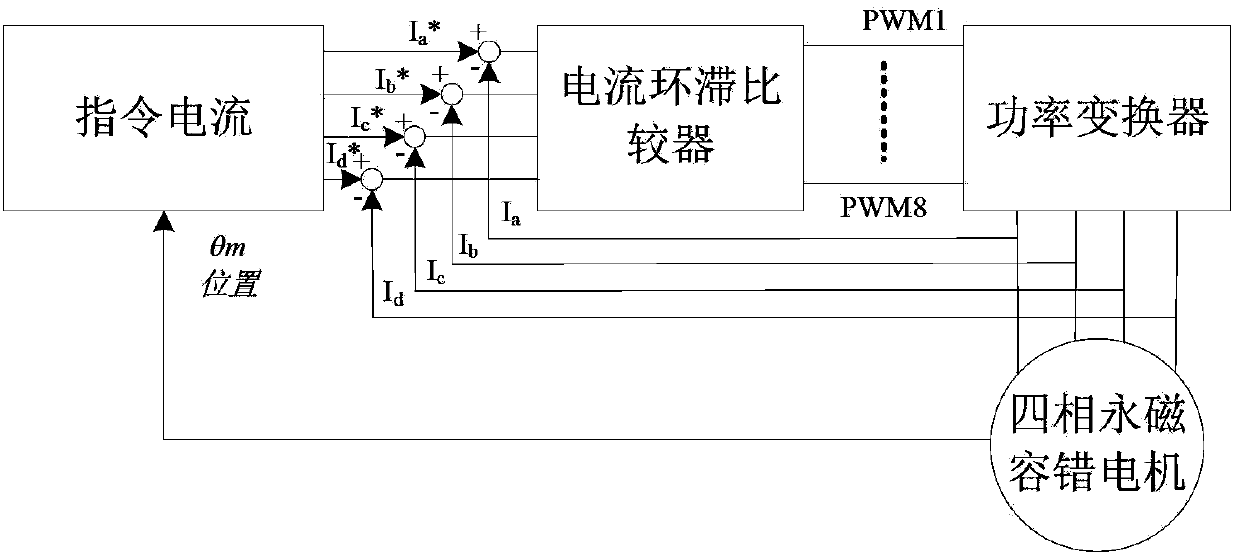

[0026] like figure 1 Shown, the system block diagram of the fault-tolerant control system of the present invention, i a * i b * i c * i d * are command currents of A, B, C, and D phases respectively, i a i b i c i d are the actual currents of A, B, C, and D phases detected by the Hall current sensor respectively, and the i can be obtained by the adder * The value of -i is used as the input of the current hysteresis comparator, and the power device is turned on and off through the output of the current hysteresis comparator.

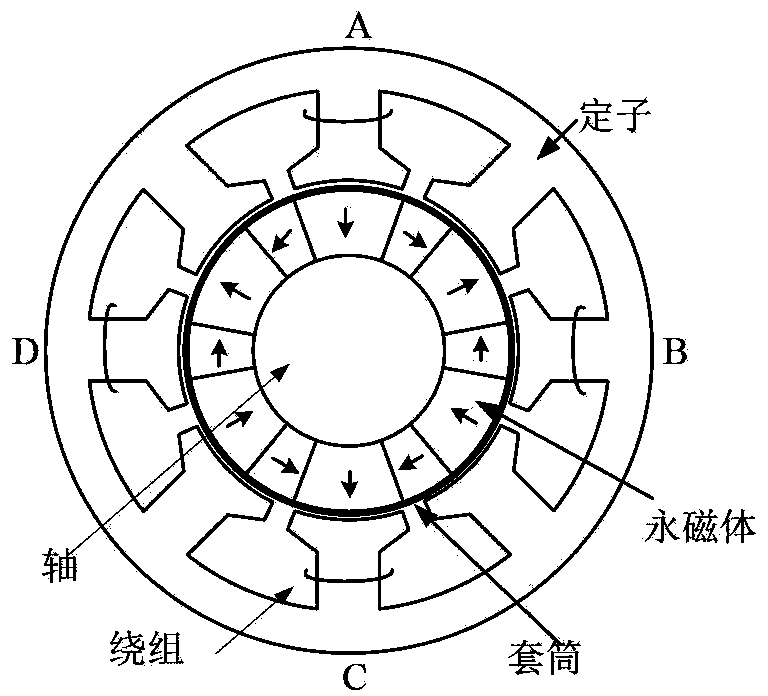

[0027] like figure 2 As shown, the stator of the four-phase permanent magnet fault-tolerant motor involved in the present invention adopts concentrated windings, and the radially opposite stator poles in space are connected in series to form a phase, and the phases are independent (this independence includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com