Air flow assisting handheld portable electrostatic spinning device and application thereof

An electrospinning, portable technology, applied in the field of hand-held portable electrospinning equipment, can solve the problems of use and product size and shape restrictions, inaccurate coating, large volume, etc., to avoid environmental problems, high degree of integration, The effect of the small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

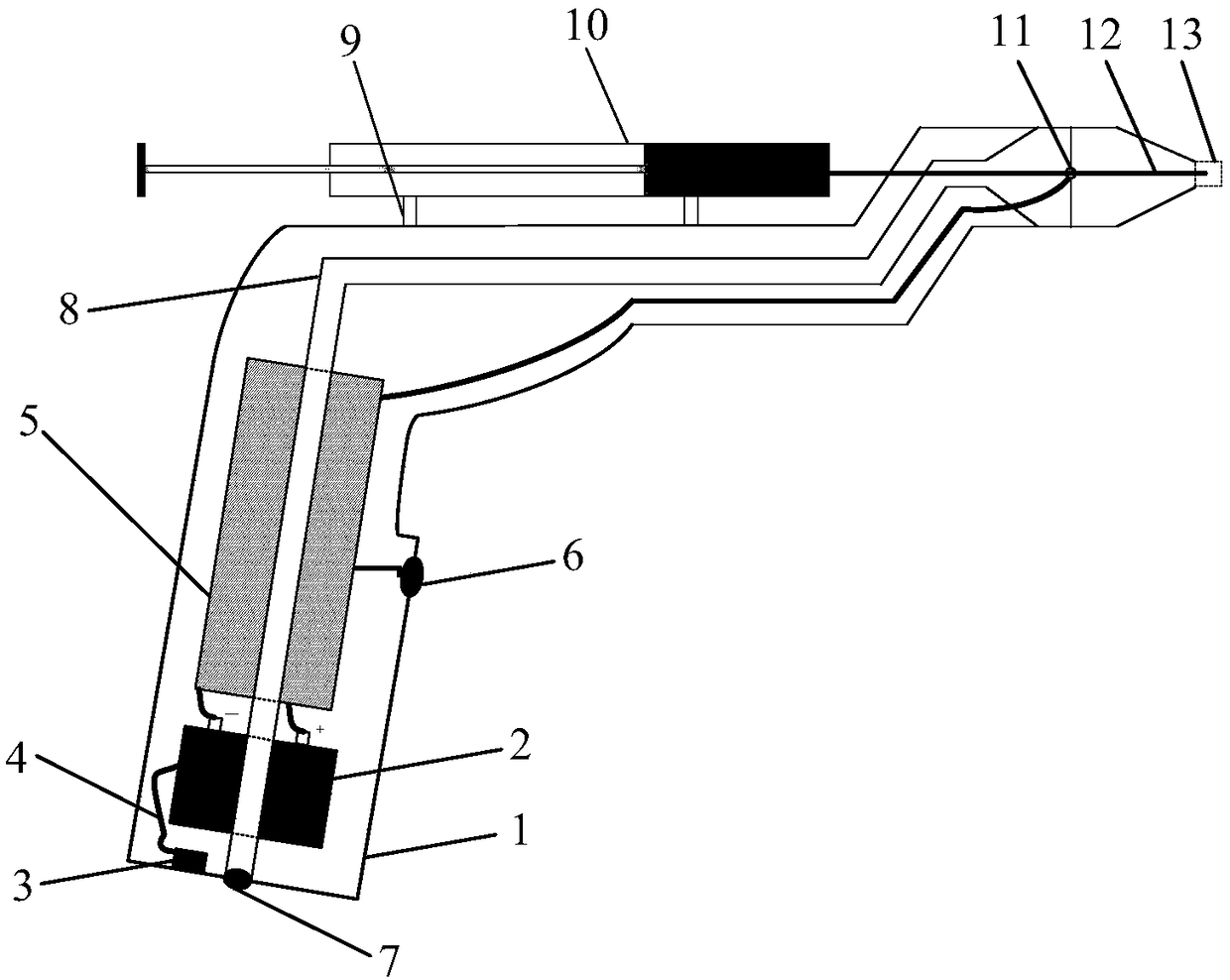

[0022] Such as figure 1 As shown, an airflow-assisted handheld portable electrospinning device according to the present invention includes an insulating shell 1, a large-capacity secondary battery 2, a charging jack 3, a high-voltage wire 4, a high-voltage static electricity generating unit 5, and a high-voltage static electricity generating switch 6 , airflow conduit connector 7, airflow conduit 8, syringe fixing bracket 9, disposable syringe 10, needle fixing bracket 11, stainless steel needle 12, airflow directional cover 13; the handle part of the insulating shell 1 is provided with a detachable insulating cover The large-capacity secondary battery 2 is connected to the high-voltage static electricity generation unit 5 and the charging jack 3 through the high-voltage wire 4; the high-voltage static electricity generation unit 5 is connected to the high-voltage static electricity generation switch 6 through the high-voltage wire 4; The inner side of the handle; the airflow ...

Embodiment 2

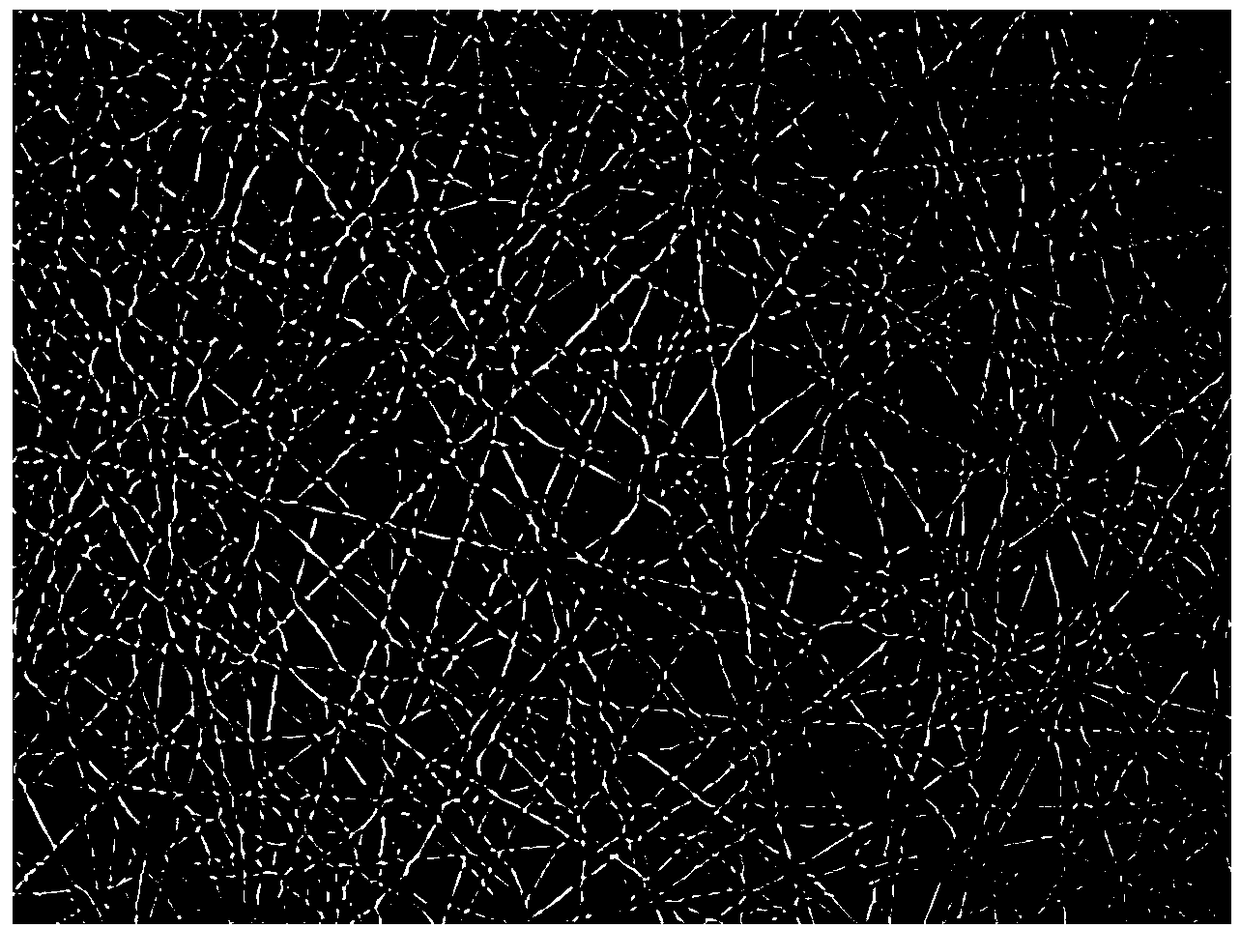

[0025]Weigh 2.0 g of polyethylene glycol and mix it with 8.0 g of deionized water, and stir it magnetically in a water bath at 40° C. for 5 hours to completely dissolve the polyethylene glycol to obtain a uniform and transparent spinning solution. Use a disposable syringe 10 to draw an appropriate amount of spinning solution, install it on the syringe fixing bracket 9, adjust the position of the stainless steel needle 12 so that its top is 5 mm away from the front opening of the airflow directional cover 13; connect the electrospinning equipment through the airflow conduit The device 7 is externally connected to an airflow generator, and the gas flow rate in the airflow conduit is 5 L / min; point the front end of the electrospinning equipment vertically to the collector, and the distance from the collector is 11 cm; press the high-voltage static electricity generation switch 6 with the index finger to make the high-voltage static electricity generation unit 5 The generated high-...

Embodiment 3

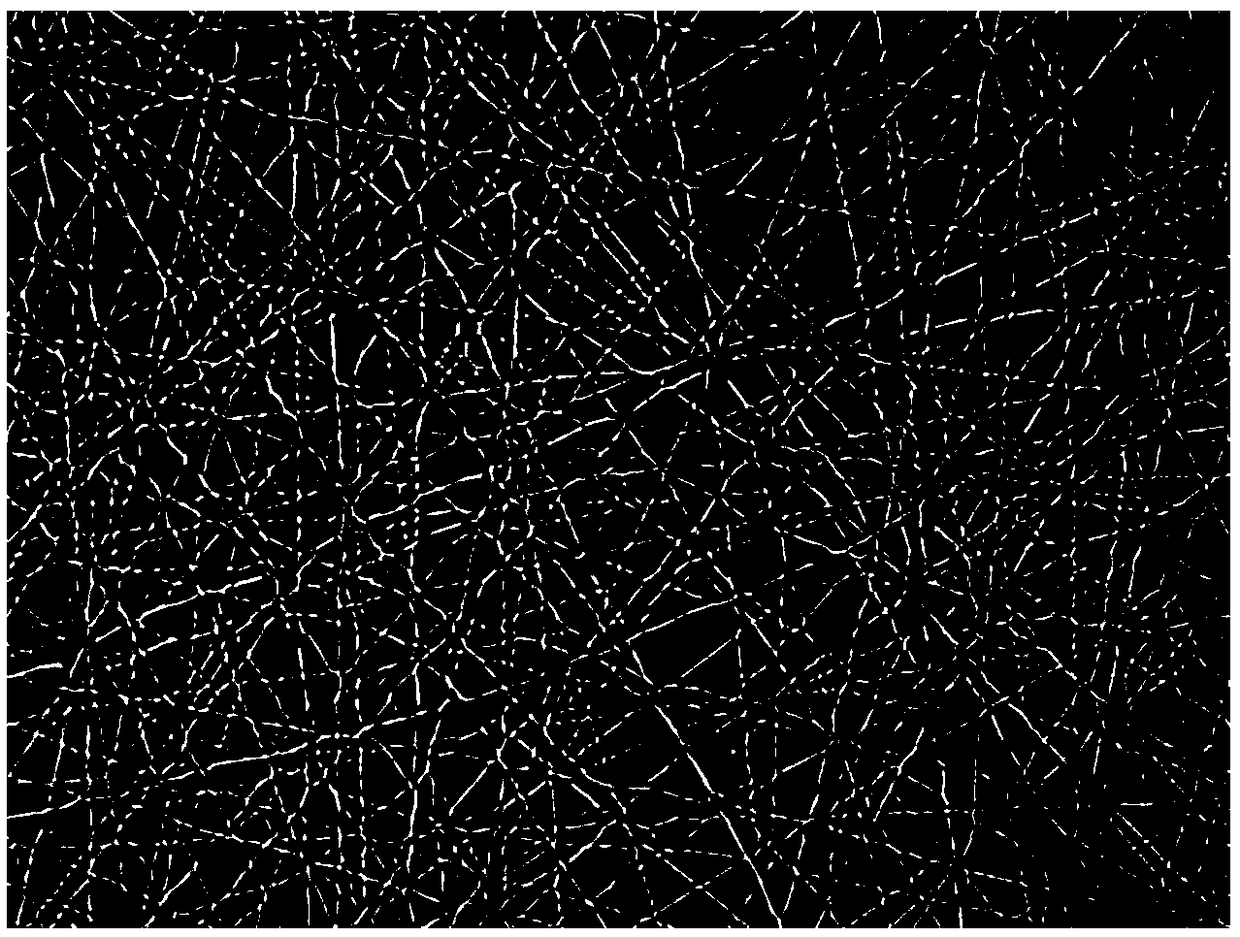

[0027] 1.0 g of polyvinylpyrrolidone (PVP) was weighed and mixed with 9.0 g of absolute ethanol, and magnetically stirred for 3 hours at room temperature to completely dissolve the PVP to obtain a uniform and transparent spinning solution. Use a disposable syringe 10 to draw an appropriate amount of spinning solution, install it on the syringe fixing bracket 9, adjust the position of the stainless steel needle 12 so that the top is 4 mm away from the front opening of the airflow directional cover 13; connect the electrospinning equipment through the airflow conduit The device 7 is externally connected to an airflow generator, and the gas flow rate in the airflow conduit is 6L / min; point the front end of the electrospinning equipment vertically to the collecting pole, and the distance from the collecting pole is 8 cm; press the high-voltage static electricity generating switch 6 with the index finger to make the high-voltage static electricity generating unit 5 The generated hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com