Method for preparing pore-size-controllable silicon carbide ceramic by means of three dimensional (3D) molding

A technology of silicon carbide ceramics and silicon carbide powder, applied in the field of 3D printing, can solve the problem of uncontrollable pore size, achieve the effect of narrow pore size distribution and ensure molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] The target product is a honeycomb silicon carbide porous ceramic tube. The macroscopic dimensions of the ceramic tube are as follows: the outer diameter is 25.4mm (1 inch), with 19 honeycomb holes, and the diameter of the honeycomb holes is 4.5mm; the filter hole diameter is expected to be 5.5μm. Its detailed preparation steps are as follows:

[0115] 1) Prepare silicon carbide raw material powder

[0116] The specific method of the first step is to use commercially available abrasive grade green silicon carbide as the primary raw material. According to the provisions of "GB / T 2480-2008 Ordinary Abrasive Silicon Carbide" and "GB / T 2481.2-2009 Detection and Marking of Abrasive Grain Size Composition for Bonded Abrasive Tools Part 2: Micropowder", the particle size numbers of purchased silicon carbide are respectively For: #1200 (coarse powder) and #6000 (fine powder). The chemical composition index of the purchased silicon carbide powder has reached the purity required...

Embodiment 2

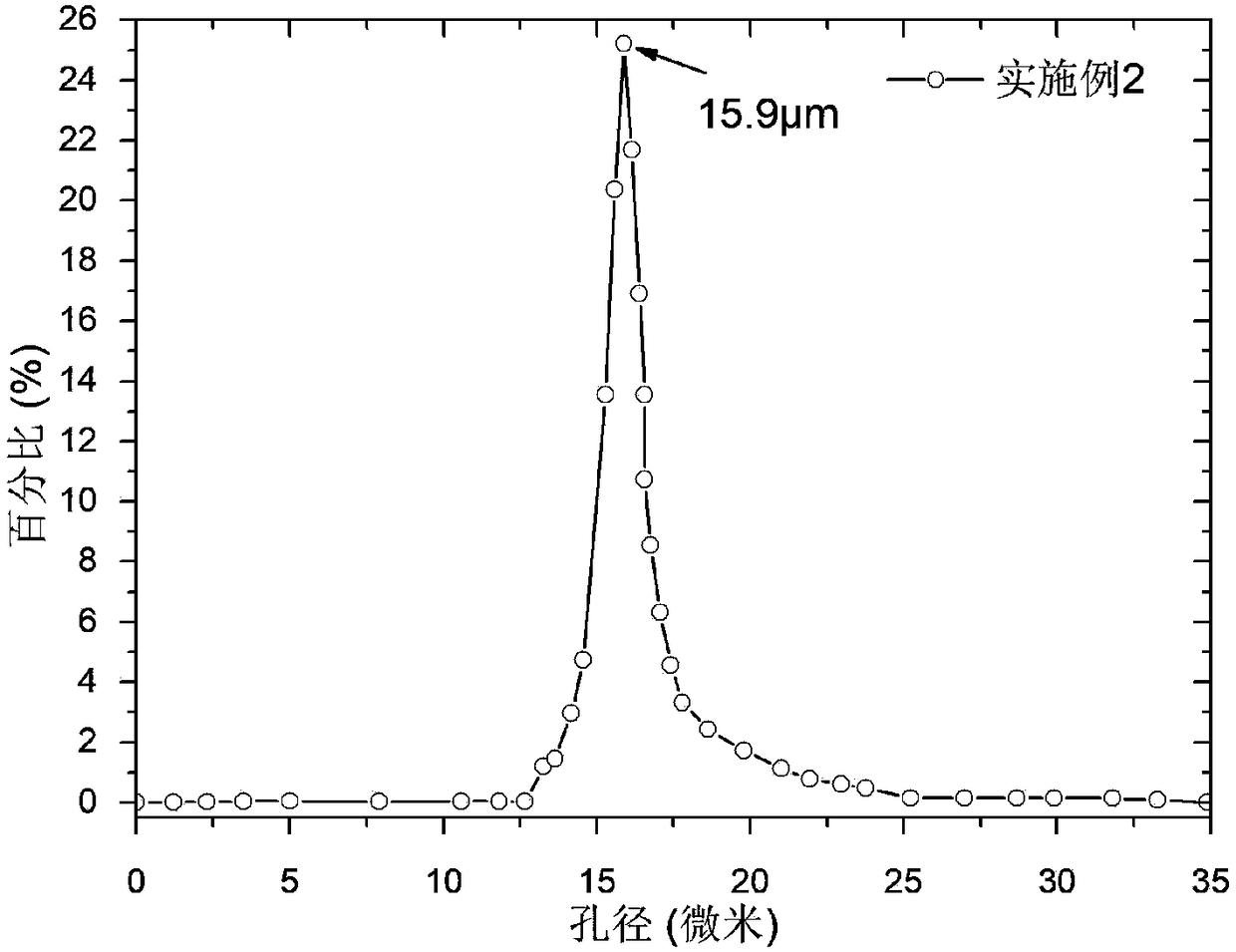

[0134] The target product is a honeycomb silicon carbide porous ceramic tube, the macroscopic shape and size of which are the same as in Example 1, and the filter pore size is expected to be 16.0 μm. Its specific implementation steps are also consistent with Example 1 except that some parameters are different. Its main parameter that is different from embodiment 1 is as follows:

[0135] 1) Prepare raw material powder

[0136] The particle size numbers of the two green silicon carbide abrasives selected as primary raw materials are #360 and #3000 respectively, and their chemical composition and density are the same as in Example 1. The sphericity, median diameter D 50 , D representing the width of the particle size distribution 95 、D 5 All have reached the requirements of the present invention for the raw material powder, and the specific values are listed in Table 2-1. Table 2-1 also lists the D 50细 / D 50粗 Value, this ratio has also reached the requirement of the pre...

Embodiment 3

[0152] Example 3 is also the preparation of a honeycomb silicon carbide porous ceramic tube, the macroscopic shape and size of which are the same as those of Example 1, and the filter pore size is expected to be 24.0 μm. Its specific implementation steps are also consistent with Example 1 except that some parameters are different. Its main parameter that is different from embodiment 1 is as follows:

[0153] 1) Prepare raw material powder

[0154] The particle size numbers of the two green silicon carbide abrasives selected as primary raw materials are #700 and #3000 respectively, and their chemical composition and density are the same as in Example 1. The sphericity, median diameter D 50 , D representing the width of the particle size distribution 95 、D 5 All have reached the requirements of the present invention for raw material powder, and the specific values are listed in Table 3-1. Table 3-1 also lists D 50细 / D 50粗 Value, this ratio has also reached the requireme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com