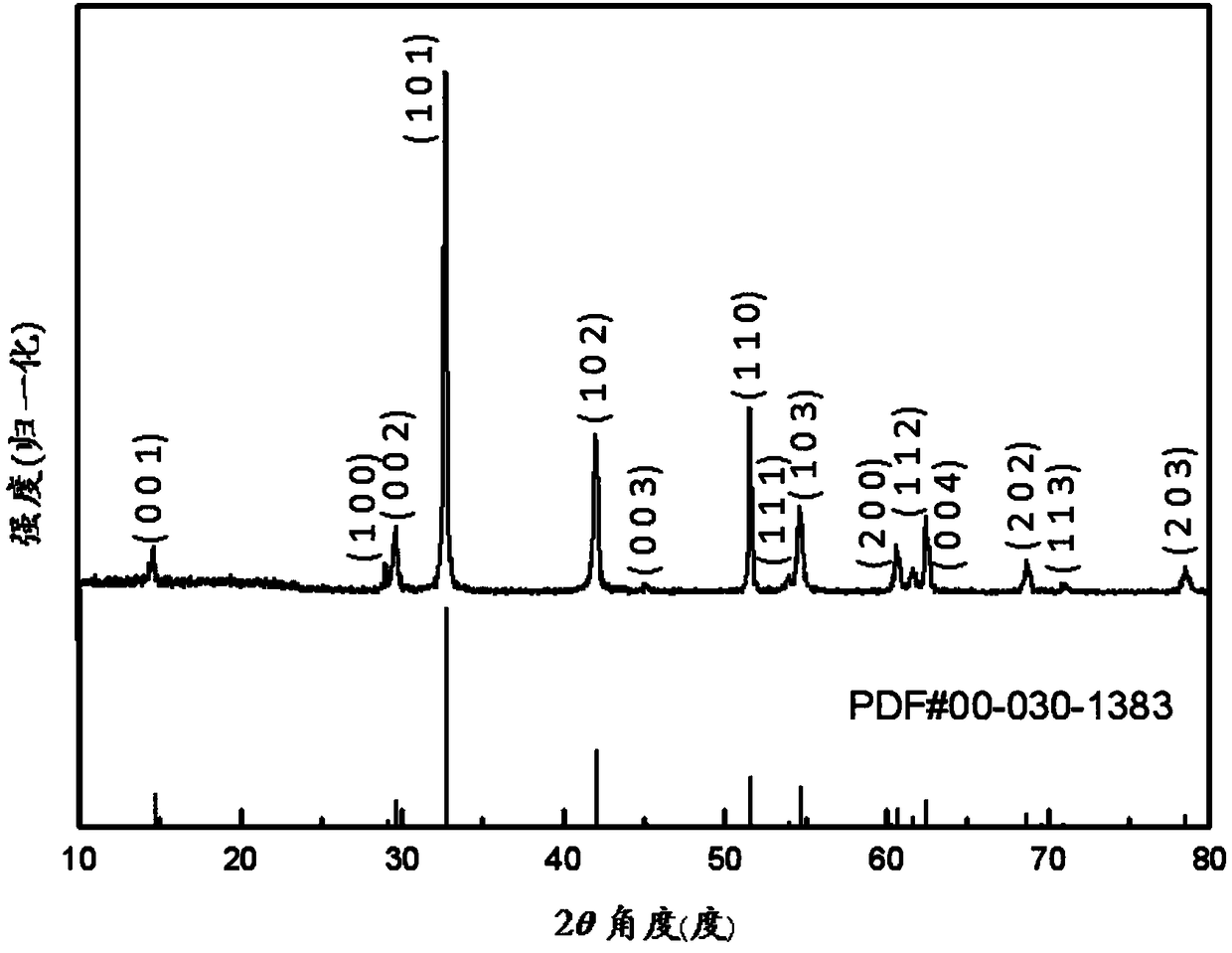

Single-phase titanium diselenium nano-sheet prepared by solution method and method and application of nano-sheet

A titanium diselenide and nanosheet technology, applied in the field of nanomaterials, can solve the problems of environmental pollution, skin burns, differences in sample components, etc., and achieve the effects of high operational accessibility, short reaction time, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] First, in a 50 mL two-necked bottle, inject 5 mL of oleylamine and 7 mL of octadecene, and disperse the selenium powder in the mixed solvent to obtain the precursor A of the selenium source. Then, high-purity nitrogen gas was introduced, the mixed solution A was stirred, and a mechanical pump was used to pump air, and at the same time, the temperature was raised to 115° C., and the temperature was kept for 35 minutes. After cooling down to room temperature, repeated gas scrubbing several times to obtain an oxygen-free and water-vapour-free environment. Subsequently, 10 mmol TiCl was added 4 , so that TiCl 4 : The molar ratio of Se is 1:0.4. Under continuous stirring and a protective atmosphere, the temperature was raised to 260° C. and kept for 30 minutes to complete the growth of nanocrystals, then the heating was stopped, and the reaction system was cooled to room temperature. Then, after centrifugation at 9500r / min, wash with ethanol and cyclohexane three times, p...

Embodiment 2

[0055] First, in a 50 mL two-necked bottle, inject 5 mL of oleylamine and 7 mL of octadecene, and disperse the selenium powder in the mixed solvent to obtain the precursor A of the selenium source. Then, high-purity nitrogen gas was introduced to stir the mixed solution A, and a mechanical pump was used to pump air. At the same time, the temperature was raised to 120 ° C, kept for 20 minutes, and repeated several times to obtain an oxygen-free and water-vapour-free environment. After cooling down to room temperature, add 10mmol TiCl 4 , so that TiCl 4 : The molar ratio of Se is 1:0.7. Under continuous stirring and a protective atmosphere, the temperature was raised to 300° C. and kept for 35 minutes to complete the growth of nanocrystals, then the heating was stopped, and the reaction system was cooled to room temperature. Then, after centrifugation at 8000r / min, wash with ethanol and cyclohexane three times, pour off the solution, and dry at 70°C for 15min to obtain a dark ...

Embodiment 3

[0059] First, in a 50 mL two-necked bottle, inject 5 mL of oleylamine and 7 mL of octadecene, and disperse the selenium powder in the mixed solvent to obtain the precursor A of the selenium source. Then, high-purity nitrogen gas was introduced to stir the mixed solution A, and a mechanical pump was used to pump air. At the same time, the temperature was raised to 130 ° C, kept for 30 minutes, and repeated several times to obtain an oxygen-free and water-vapour-free environment. After cooling down to room temperature, add 5mmol TiCl 4 , so that TiCl 4 : The molar ratio of Se is 1:2. Under continuous stirring and a protective atmosphere, the temperature was raised to 240° C. and kept for 60 minutes to complete the growth of nanocrystals, then the heating was stopped, and the reaction system was cooled to room temperature. Then, after centrifugation at 9000r / min, wash with ethanol and cyclohexane three times, pour off the solution, and dry at 75°C for 15min to obtain a dark bro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com