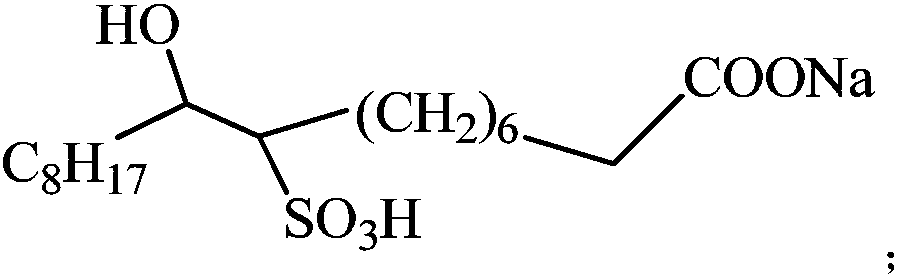

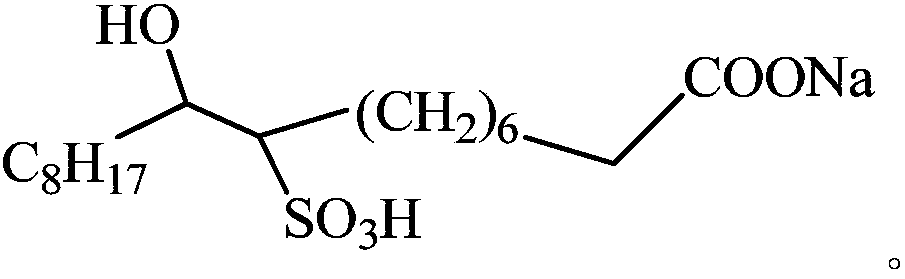

Hydroxy sulfo-group stearic acid soap collecting agent and preparing method thereof

A technology of hydroxysulfostearic acid and hydroxysulfostearin, which is applied in the field of collectors, can solve problems such as failure to meet collophosite beneficiation requirements, inability to transport beneficiation agents, increase in beneficiation production costs, etc. High beneficiation effect, good collection performance, and low beneficiation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

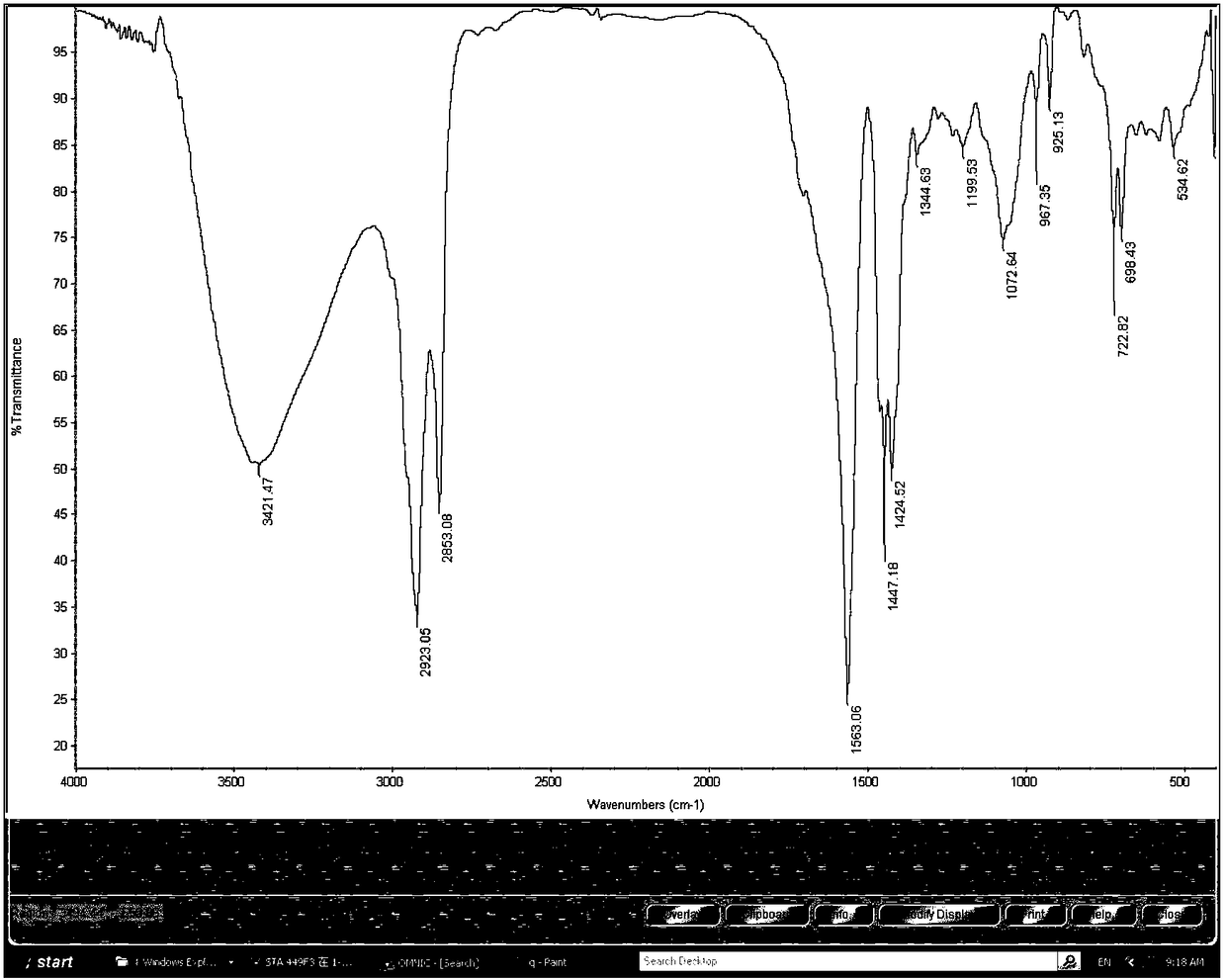

[0026] Preparation of hydroxysulfostearic acid soap collector, concrete steps are as follows:

[0027] Get 40g oleic acid in the beaker, slowly add the vitriol oil of 0.8g 98% and 3.20g acetic acid (99.5wt%), add 16.04g hydrogen peroxide (30wt%), stir and be warming up to 60 ℃ of reaction 4 hours, after reaction finishes, add The reaction solution was transferred to a separatory funnel, and the aqueous solution of the lower floor was separated, and the organic phase was washed several times with water to obtain epoxy stearic acid.

[0028] Take 45g of the above-prepared epoxy stearic acid in the reactor, add 9g of sodium bisulfite and 18g of water, stir and raise the temperature at 65°C for 4 hours, separate the water phase after standing, and wash the organic phase with water several times to obtain hydroxysulfonate base stearic acid.

[0029] Weigh 50g of the above-prepared hydroxysulfostearic acid, 10g of sodium hydroxide, 39g of water and 1g of diethyl phthalate into a fl...

Embodiment 2

[0033] Preparation of hydroxysulfostearic acid soap collector, concrete steps are as follows:

[0034] Get 200g of oleic acid in a beaker, slowly add 4.0g of 98% concentrated sulfuric acid and 16g of acetic acid (99.5wt%), add 80.2g of hydrogen peroxide (30wt%), stir and heat up to 60 ° C for 4 hours, and then react Liquid is transferred in the separatory funnel, separates lower floor aqueous solution, and organic phase is washed several times with water, obtains epoxy stearic acid.

[0035] Take 230g of the above-prepared epoxy stearic acid in the reactor, add 45g of sodium bisulfite and 90g of water, stir and raise the temperature at 65°C for 4 hours, separate the water phase after standing, and wash the organic phase with water several times to obtain hydroxysulfonate base stearic acid.

[0036] Weigh 250g of the hydroxysulfostearic acid prepared above, 50g of sodium hydroxide, 195g of water and 5g of diethyl phthalate (diethyl phthalate, the mixture of diethyl terephthala...

Embodiment 3

[0038] The hydroxysulfostearate saponite collector prepared in Example 1 and Example 2 is used as the collector respectively, and the collided phosphate rock provided by Guizhou Batian Phosphorus Chemical Co., Ltd. is carried out by reverse flotation process , the chemical composition of the main elements of the glenite is shown in Table 1:

[0039] Table 1

[0040]

[0041] The specific flotation method is as follows: Grind the collophosite until the mass fraction of the grinding fineness -0.074mm reaches 85-90%, pour it into the flotation tank, add water to obtain a pulp with a mass concentration of 33.3%, and use 10% dilute sulfuric acid Adjust the pH value of the pulp to 4-5, and add phosphorus inhibitor (phosphoric acid), and then add the collector to the pulp, the addition amount is 1.56kg / t collophosite (the cost of the collector is about 9.36 yuan / t ore ), fully stirred evenly, and then the dolomite was floated out in the flotation cell by a rough and two-sweep pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com